Did it ever cross your mind how CNC bending work amazingly? It is really interesting to see how this approach can generate intricate metal shapes utilized everywhere from fabricating auto parts to sculpting amazing art. In this article, we are going to take in-depth look at CNC bending and learn more about the advantages and disadvantages of using it.

CNC bending is an advanced process that uses CNC (computer numerically controlled) machines to shape metal in specific ways. And it is thisi acronym which makes the magic (-or far more mundane-) happen, purely because of these three letters: CNC (Computer Numerical Control). This technical wonder allows the expert engineerto input precise figures for each parameter in order to make this machine form any sheet of steel at one swift, sure stroke. This gives a very tiny margin of error and hence shapes achieved were accurate to the perfect mm.

Air bending is one of the core repertoire techniques in CNC bending. In this method, the machine employs a series of dies to exert pressure on the metal and coax it slowly into shape. The amazing part is that the dies never touch the metal, giving you control of how much bend angle you want by using those distances from 1 die to another. With careful control of this distance and how hard the hammer is being hit on both sides, a technician can create fine levels of detail within some pretty specific shapes with ease.

The second important factor is the design software that CNC bending machinery uses. Metal is put through the bending process after a designer with experience draws from it and creates an advanced blueprint of what the shape should look like. This software in turn creates the commands that CNC machine will use to bend metal. Superior design software is also key; you want your end product to be consistent and accurate every time.

CNC bending is a modern technology, but it has already started its way to change the face of production. Its unique accuracy is perfect for producing parts in machinery, cars and countless other mechanical components. For a long time these were all handmade, an ancient process that took forever and resulted in parts slightly different not just each year but sometimes with every batch.

In a CNC bending operation, where only one angle change itself takes 10 minutes of down time for the setup crew and will take about another half hour to run in production mode (assuming you want two parts per minute) without pressing that stop button once. This not just saves time yet also reduces the odds of blunders and flaws. In addition to this, the efficiency extends beyond just having more hands on deck it stretches over increase productivity which allows factories to produce additional material with fewer employees that in turn saves costs and progresses operational efficacy.

On the other end of its long industrial applications list, we see CNC bending stepping into creative that it has never been before. This technique is being employed by artists who are creating some truly stunning metal works, and fashion designers using this technology to produce custom-designed jewelry and accessories. The opportunities look endless, and it goes to prove the flexibility of CNC bending across diverse industries.

Then how does CNC bending make the magic wand? The first step is to design a blueprint of the final shape you want, then use specific capable software. Once the design has been approved, a technician places your metal sheet onto one of our CNC bending machines.

This smart device is two main parts, which are upper and lower dies. The technician then programs the machine to apply force along this die, bending the metal sheet (between both dies) into shape. The technician can adjust these bend angles and radii depending upon the required bending by changing the die-to-die distance or applying a certain amount of force.

As soon as the metal has been bent, it is extracted from the machine and carefully checked for notches or difference between tha actual size and desing. If all the test criteria are met, that part is considered to be qualified for its intended purpose.

The Pros And Cons Of CNC Bending For Industrial Use cases into the open

As we have seen, enough advantages in industrial CNC Bending applications. Not only does its precision, consistency and efficiency save time / money but it also lifts product quality. Secondly the CNC bending is a very versatile process, it allows manufacturers to create components that are designed for their specific needs.

However, however there are some limitations in the process. An important limitation is that bad bending can only be used in sheet metal. Alternatively, for any part that requires a cumulative angle(s) and must be curved there may have to look at alternative manufacturing processes. The tooling costs of CNC bending also be high, which may prevent smaller enterprises or individuals from taking advantage.

Nonetheless, with these constraints in place CNC bending remains a powerful asset for many modern manufacturing and metalworking processes. With how fast technology progresses, it is only a matter of time before we see evolutions of the product that improve its overall experience. For example, the use of lasers to direct the bending process is being investigated by some companies as a means of achieving accuracy at unmatched levels.

Following best practices can help manufacturers achieve the most out of CNC bending. The technology utilized to develop the best Swiss movement replica watches includes high-end materials, fine-tuned machineries, and regular inspections or maintenance checks to guarantee functionality.

In the end, CNC bending is an exciting process from many perspectives. CNC bending offers so many possibilities for us, if we are an artist who wants to create masterpieces in the form of sculptures or a fashion house that develops tailor made accesories or also its used by some mechanical engineers printing very complex components This full-fledged guide is designed to give a better understanding of CNC bending and its various usages.

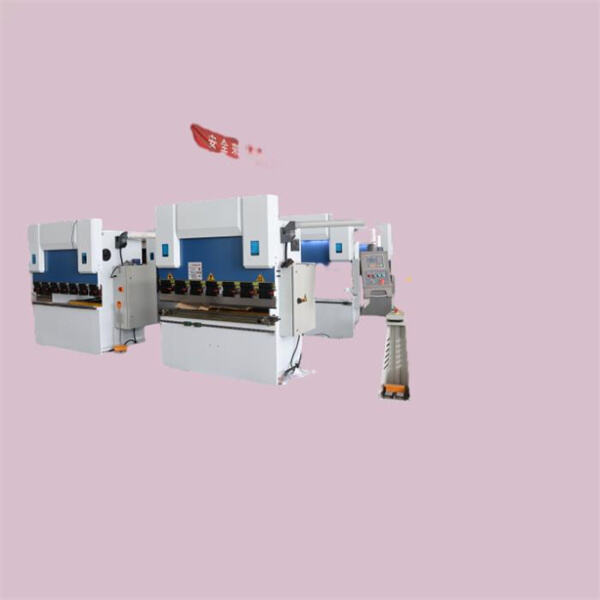

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Cnc bending capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Cnc bending aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Quality Builds Trust: Cnc bending sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

Rolling Machines Cnc bending metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.