Cut presses are some of the shiniest equipment in steel work market. These high-precision machines bend metal into complex shapes with amazing precision, thanks to state-of-the-art accuracy technology. A break press is used to bend sheet metal, and it takes a skilled operator with the ability to adjust the machine so that you can get your square piece of iron bent at just whatever weird angle our aerospace engineers conjured up; thus we have humans augmenting technology.

Unquestionably, break presses are the most flexible piece to work withanding among them is container. These types of devices may be used to develop a numerous diverse shapes and portions made from steel, through single angle-brackets each senseless prop aircraft features. This adaptability is what makes the break press versatile, as you can pick and attach different tools to it in order to give your pieces any desired angle/cure/etc.

Break presses provide an important service to the industrial manufacturing world. Replacing the traditional labor-intensive and time-demanding metal bending methods, break presses have revolutionized efficiency and productivity in the industry. Due to the speed and accuracy at which breaks presses operate, larger volumes of products can be produced much quicker; hence businesses also gain productivity here on a large scale.

Between the growing sector of metalworking, break presses have become a one-of-a-kind alteration in how production works. They proved effective and efficient which raised the temptation for huge manufacturing companies to use them, thus cutting down on time and costs. Now with break presses, businesses are able to produce a greater quantity of good quality products at an increased pace=growing profitability and their competitive position within the global market place.

In short, profile rolling machinery is an outstanding device in the metalworking sector as it helps in fast and accurate shape-changing of metals. More versatility and efficiency has made them the major disruptors of the manufacturing world; helping users significantly improve productivity breaking free to a whole new level. The future of metalworking has never shone so bright, with break presses taking the lead.

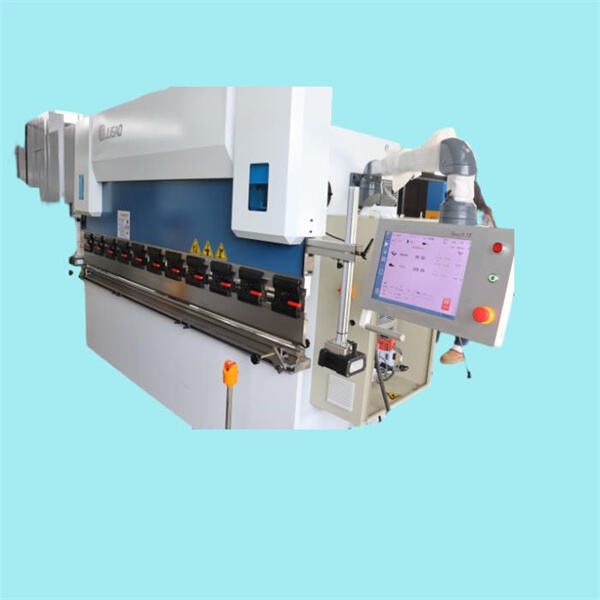

Rolling Machines Break press metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.

Quality Builds Trust: Break press sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Break press capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Break press.