Metal press fabrication is a process of manufacturing. What this means is it a method of manufacturing parts that will work in many applications. For this, it employs special machines that are used to shape and cut metal into the desired shapes. The JUGAO process can be used across a diverse range of metals which allows for it to produce metal parts utilised in cars, furniture such as tables and chairs or even components inside structures. It is said that no work shall commence before the production of a drawing or detailed sketch. Built In this often refers to as a blueprint When the design is finished, they create a piece of true metal with a metal press machine that we can see and touch.

Worker follow special steps during metal press fabrication process. The metal press and bend first thing they do is to model the object that needs to be produced in a computer programme. This is a very helpful computer program as it prepares the complete digital blueprint. This blueprint is similar to a map, which tells the metal press machine how it should be shaped by pressing.

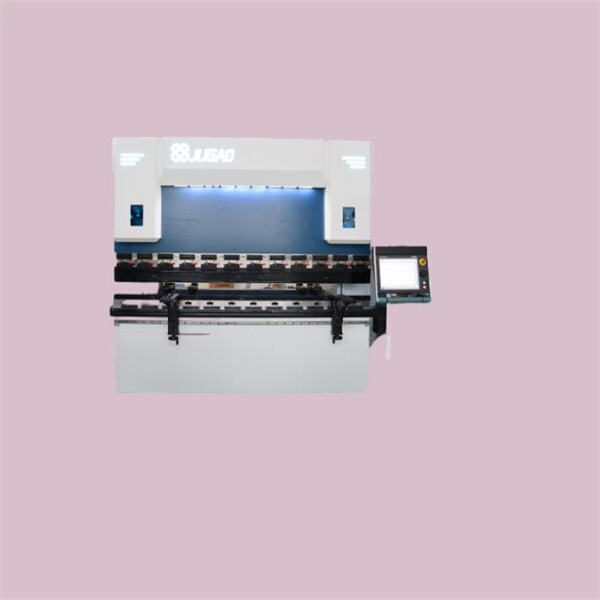

After selecting the appropriate metal, workers will use a punch press machine to form and cut out process using Object. A metal press machine is immensely robust and exerts a large amount of force to bend, fold or cut the pieces metallic sheets. This is why workers need to be very careful and pay attention when working with this machine.

Last but not least, when the metal has been properly shaped and cut to size, it may undergo additional tools to give that final touch. One final step that may be taken is finishing the metal, which JUGAO can include applying a coating to protect it from rusting (rust happens with untreated metals when they get wet). They metal press bender could include other adornments to make the object prettier as well.

Press Metal Fabrication is a crucial procedure for multiple sectors. Car makers use this technique to produce just about everything you see on a car -doors, hoods and even engine parts are made with metal press fabrication. Furniture makers also make use of this metal press brake process to manufacture strong metal parts such as chairs, tables and other furniture articles. It is interesting that even in the medical field, metal press fabrication will be used when creating significant components of various life-saving devices like tools or similar - equipment which then helps doctors to save lives. This JUGAO is a sign of how important he metal press fabrication are in our everyday lives,

Metal press fabrications are crucial, which is why this step alone in Press metal fabrication ensures a better quality control. This means that when fabricators are making metal parts, they have to make sure everything is up to a certain standard. Item standard dimensions i. e. size and shape, its strength etc This metal press brake for sale is what happens when workers do not assess the metal for quality; a metallic object could become harmful or non-functional.

As with most other forms of manufacturing, new tools and technology are altering how sheet metal press fabrication functions. Brand new computer programs are aiding workers design metal objects much more quickly. In addition new machines that sculpt metal objects with more accuracy and detail are being designed. This Punching Machine allows for faster manufacturing of metal objects than ever before.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed Metal press fabrication cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

Metal press fabrication importance RD support after-sales. press brakes, laser cutting machines, rolling machines pipe bending equipment items, offer extensive range after-sales support includes Spanish after-sales service, ensure customers able use product without worry. continuing invest product development upgrade technology innovation. allows us meet evolving customer requirements keep leadership position market.

Quality Builds Metal press fabrication: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Metal press fabrication, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.