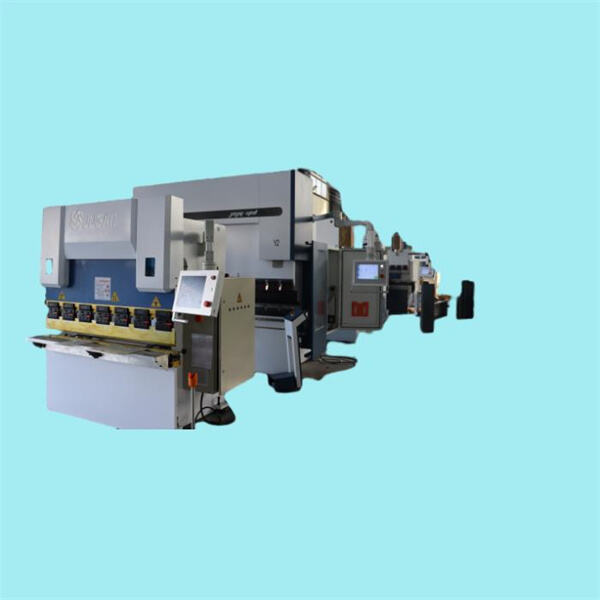

A metal press and bend is a metalworking machine of heavy caliber used to bend and modify metal accurately. We at JUGAO really take pride in our metal press bender and all that it can do. Let’s delve deeper into how this awesome machine operates and how it is revolutionizing manufacturing.

The metal press bender at JUGAO is a large machine that uses a hydraulic system to press down on metal sheets, so that they bend. It has a durable frame and a robust motor that gives it the strength it needs to bend even heavy metal sheets. The one certainty in the manufacturing process is the skill required to operate the machine and ensure each bend measures up.

Just like any material, bending metal correctly takes practice and skill. At JUGAO, our workers are trained to use the metal press bender correctly. They discover how to fix the machine, tweak the pressure and even form exacting corners to produce high quality metal products.

At JUGAO we have a metal press bender that can bend metal into different shapes and angles. It can bend sharp corners, smooth curves, as well as complex shapes. This equipment is designed for bending variety of metals such as steel, aluminum and copper. Its possibilities are boundless, an essential instrument in industry.

With the metal press bender, manufacturers can produce a wide variety of metal products as fast as you please. The machine is in place to save time and money, with the ability to automatically perform bending. It also ensures the results are uniform, resulting in quality metal parts that can comply with industry guidelines.

Metal press benders have revolutionized the manufacturing world – offering a faster, more efficient way to bend metal all employment opportunities naturally advertise the same job because make, model and shape of the machine are readily available; however, the sensitivity and efficiency are maintained. They make metal products more quickly — resulting in faster production rates and lower costs. Press benders for metal also provide higher quality of metal parts due to the level of precision that press benders can deliver and to the accuracy of the bends and forms. Thanks to that, industrialists can manufacture metal-based products of higher quality in shorter time frames, enabling them to stay competitive on the market.

precision efficiency, metal press bender cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe metal press bender. product range focused efficiency, precision, stability help customers improve production efficiency quality products.

recognize importance service sales metal press bender advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Quality metal press bender Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.