Hydraulic press brakes are powerful equipment used to bend and mould metal with hydraulic pressure. They’re commonly employed in factories to form various metal products, such as parts for cars, appliances and furniture. So now I am going to explain you about hydraulic press brakes and importance in forming the metal.

Once upon a time, it was quite challenging to work with metal and required a significant amount of manual labour. With 350 ton hydraulic press, though, things have changed significantly regarding manufacturing. With these machines, you can bend metal fast and it also provides the precision and this makes your manufacturing process a heck of a lot easier.

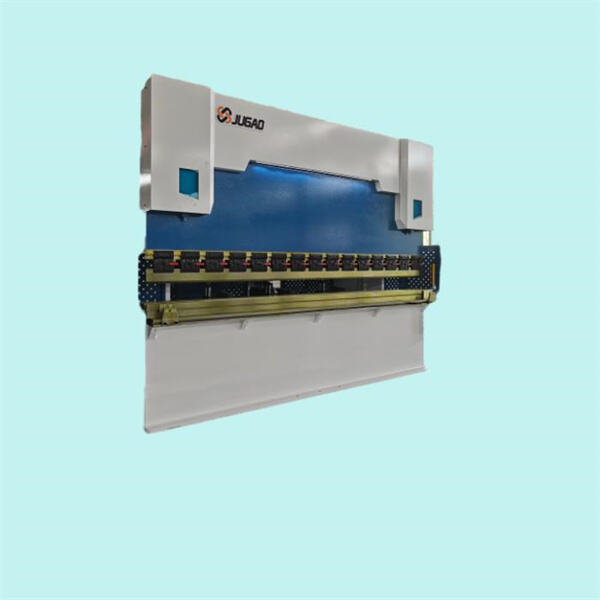

The main components of a hydraulic press brake include a Hydraulic cylinder, a ram, and a die. The hydraulic cylinder creates the force required to bend the metal. The ram is the bending part of the machine. The die is a special tool used to shape the metal into the desired shape.

A major advantage of hydraulic press brakes is that they enable factories to work faster. These machines are able to quickly and accurately bend metal so that companies can produce multiple products in less time. This is how businesses make more money.

Hydraulic press brakes are extremely versatile machineries that can produce a variety of products. These machines are capable of much more than basic bends. Their adaptability is why they’re becoming increasingly useful tools in areas such as car making, aerospace and construction.

recognize importance service sales hydraulic press brakes advancement. laser cutting machines, rolling machines, pipe bending machines, products, provide full range after-sales assistance includes Spanish after-sales services, ensure customers worry-free use. continue invest product development upgrade using latest technologies. helps meet evolving customer requirements keep top position market.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe hydraulic press brakes. product range focused efficiency, precision, stability help customers improve production efficiency quality products.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; hydraulic press brakes, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain hydraulic press brakes advantages.