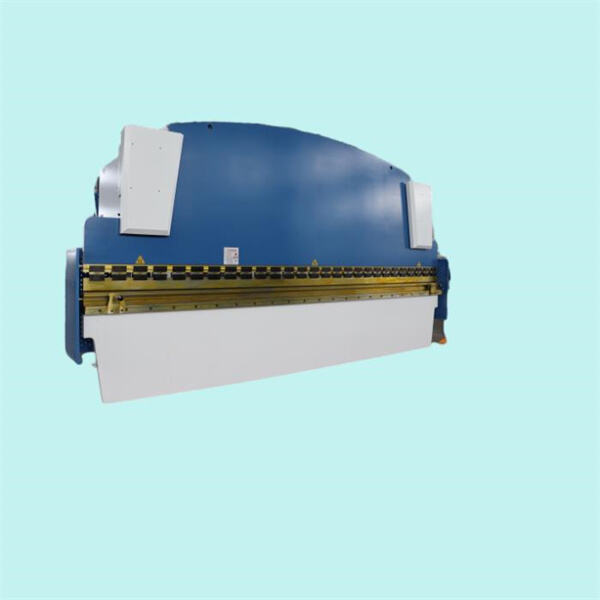

A brake is a tool you use to bend and shape metal sheets. It has a flat part, called a bed, on which the metal rests. There is also a clamping bar that secures the metal. A press beam pushes it down to bend the metal the way we want.

Precision is being very accurate. Very useful when it comes to bending metal. If it’s just off a little bit, the metal may not bend right, and that will make a poor product. So technically, we measure using instruments we call calipers and rulers. Moreover, it is necessary to position the metal right and apply exact strength.

New technology has rendered brake systems more efficient and precise. These CNC (Computer Numerical Controls) machines can be programmed to very accurately bend metal. Hydraulic systems aid by providing a constant pressure, so the bends are consistent every time.

Brake machines require maintenance to stay healthy. That includes cleaning the machine regularly and looking for loose or worn parts and oiling moving parts. If something is wrong, we can fix it in a hurry before more damage is done. Some common ones are ineffective bending, unusual noises and slow speed.

Brake machines also require the use of safety precautions. Workers should be appropriately dressed in protection gear such as gloves and safety glasses to protect themselves from injuries. And you should adhere to machine’s rules and not discount safety features. In case of emergency, workers need to know where the emergency stop buttons are located and how to use them.