- Overview

- Inquiry

- Related Products

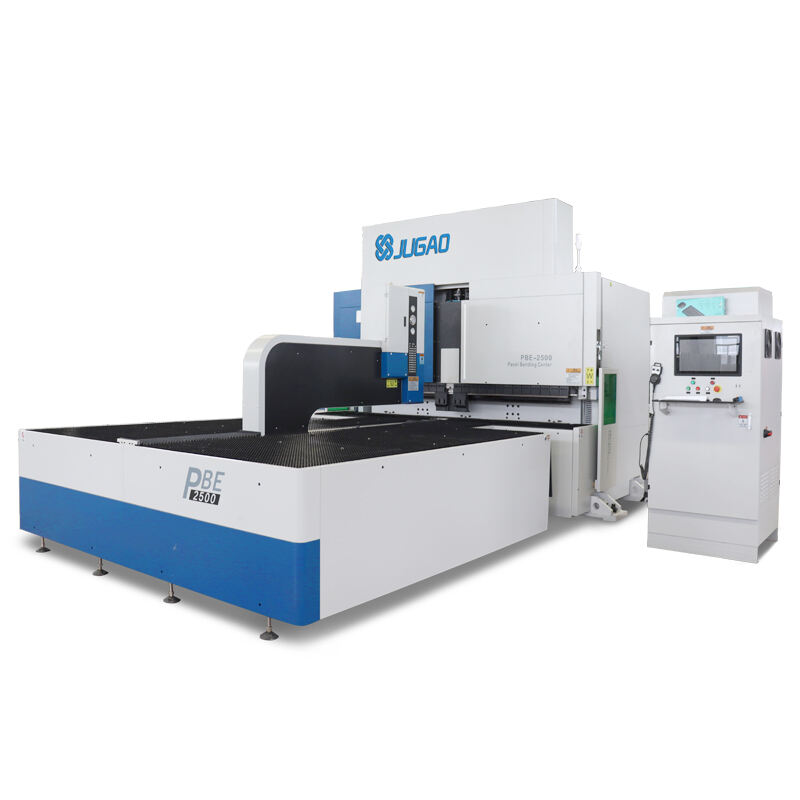

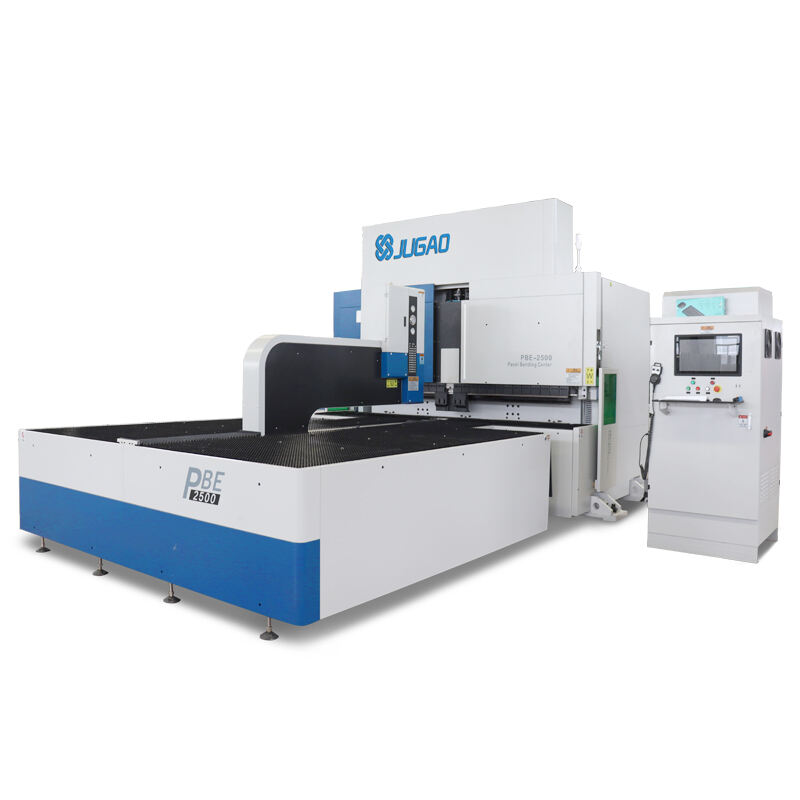

Panel Bending Center is a new generation of fully automatic multi-sided bending center. It is a benchmark product for the sheet metal manufacturing industry to enter automated production. The product not only saves manpower to a large extent, but also has a bending speed that is three times that of a CNC bending machine, reaching 0.3S/time. Full servo control closed-loop bus.

Product Features

• Fully automatic folding, high efficiency, energy saving, and environmental protection

• Bus control, can be directly connected to the Internet of Things for remote control and grid-connected monitoring

• Special high-load-bearing screw and guide rail structure, imported bearing installation

• High load-bearing capacity, high positioning accuracy, and long life

• Fully automatic lubrication system, automatic centralized lubrication of the whole machine, maintenance-free

Models above 2000 have double servo rotation up and down, and the automatic pressing structure presses down quickly, the pressure is adjustable, and the rotation positioning accuracy is high.

Technical parameters

| Name | Unit | PBE-3000 | PBE-2500 | PBE-2000 | PBE-1400 | ||||

| Maximum bending length | mm | 3000 | 2500 | 2000 | 1400 | ||||

| Maximum bending width | mm | 1250 | 1250 | 1250 | 1400 | ||||

| Maximum bending height | mm | 170 | 170 | 170 | 170 | ||||

| Minimum bending height | mm | Ball head*2 + plate thickness | Ball head*2+plate thickness | Ball head*2+plate thickness | Ball head*2+plate thickness | ||||

| Maximum rotation diameter | mm | 3250 | 2800 | 2360 | 1780 | ||||

| Minimum positioning width | mm | 200 | 200 | 200 | 200 | ||||

| Maximum positioning width | mm | 3020 | 2520 | 2020 | 1420 | ||||

| Minimum forming size of opposite sides | mm | 200 | 200 | 200 | 200 | ||||

| Minimum forming size of one side | mm | 170 | 170 | 170 | 170 | ||||

| Maximum positioning width | mm | 3020 | 2520 | 2020 | 1420 | ||||

| Bending angle | ° | Positive and negative 0-180 | Positive and negative 0-180 | Positive and negative 0-180 | Positive and negative 0-180 | ||||

| Model | Standard | Heavy duty | Standard | Heavy duty | Standard | Heavy duty | Standard | Heavy duty | |

| Maximum pressing force | T | 115 | 155 | 80 | 115 | 38 | 53 | 28 | 38 |

| Bending thickness - stainless steel | mm | 1.2 | 1.5 | 1.2 | 1.5 | 1.2 | 1.5 | 1.2 | 1.5 |

| Bending thickness - aluminum plate | mm | 2 | 3 | 2 | 3 | 2 | 3 | 2 | 3 |

| Bending thickness - cold plate | mm | 1.5 | 2 | 1.5 | 2 | 1.5 | 2 | 1.5 | 2 |

| Minimum bending thickness | mm | 0.35 | |||||||

| Host power | Kw | 88 | 100 | 60 | 70.5 | 49 | 56 | 40 | 44 |

| Average energy consumption | KWH | 4.2 | 4.8 | 2.9 | 3.4 | 2.4 | 2.7 | 1.9 | 2.1 |

| Voltage frequency |

380V 50/60HZ 3-phase 5-wire |

380V 50/60HZ 3-phase 5-wire |

380V 50/60HZ 3-phase 5-wire |

380V 50/60HZ 3-phase 5-wire |

|||||