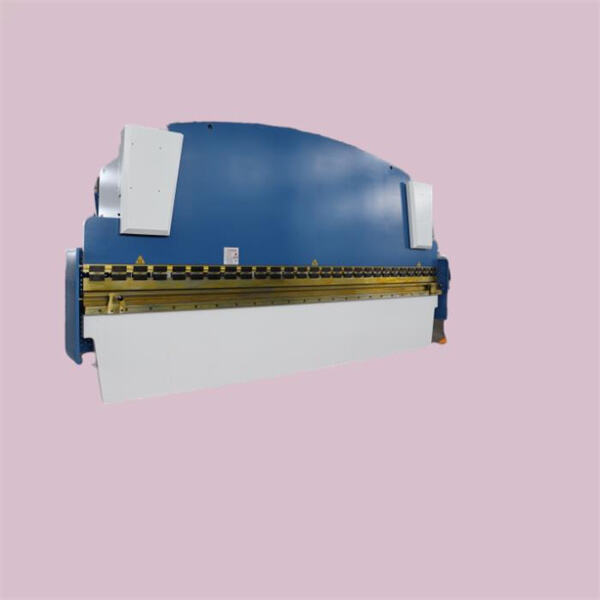

What is An Electric Press Brake An electric press brake is a machine that is very useful in metalworking in order to bend and shape metal sheets. It does this by pressurizing the metal with electric force, which can then be bent into different shapes. A flat bed on which the metal sheet is placed and a large, strong press are parts integral to the machine and are used to apply the force required to bend the metal. The automatic press brake operates a computer system to guarantee that bends are always equal.

One of the best benefits of the JUGAO electric press brake is the fact that it is efficient. While traditional press brakes need to be operated by hand, a big press brake can be programmed to make multiple bends on its own. This saves a large amount of time and labor for the execution of a project, providing a higher yield and faster turnout. Moreover, computer-controlled bending also means that every bend is identical and perfect, and the finished products are of superior quality.

There are some advantages of an electric press brake in whip up industry. one of its greatest benefits is its flexibility. Electric press brake can also bend a variety of materials, such as steel, aluminum, and copper, and the machine can be used for multiple applications. They also provide quicker setup times and faster cycle times than a cheap press brake, which gives you the ability to increase production and decrease lead times. Electric press brakes are also more environmentally friendly and more energy efficient electric versus hydraulic press brakes offer safer, green manufacturing solution energy efficient to the manufacturer.

There are a number of elements to take into account when you are selecting an electric press brake for your business. Start by figuring out the dimensions and thickness of the metal sheets you plan to handle, which can guide you in choosing a JUGAO press brake capacity. Also take into account what you will be bending and how accurate the bends need to be. Lastly, consider the physical space in your venue and any particular needs or special requirements. Cautious consideration of these considerations will allow you to pick the right electric press brake for your production.

When working with a JUGAO best press brake machine, safety is the primary concern. For safety of you and others, always use personal protective equipment including gloves and safety glasses when using the equipment. Also read and follow the manufacturer's operating instructions and procedures for equipment. Keep the workplace clean and tidy and not move any material to use as a space. Even you can not move the material to work when the machine is working. By adhering to these guidelines and using common sense, you could reduce the risk of accidents when operating an electric power press brake machine.

Electric press brake Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

Electric press brake accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy Electric press brake experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.

Rolling Machines specialize metal sheet forming production quality. Pipe Bending Machines offer flexible solutions pipe Electric press brake. product range focused efficiency, precision, stability help customers improve production efficiency quality products.