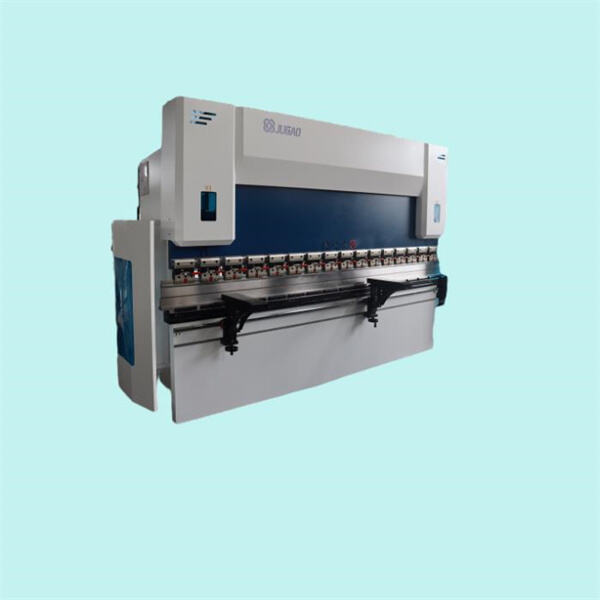

CNC press brake bending tools are powerful tools for shaping and bending sheet metal. These machines rely on a sophisticated process called computer numerical control (CNC) to ensure that the angles and bends in the metal are exact. JUGAO is popular for their sales of CNC press brake machines. They’re known for building well-made machines that function.

CNC press brake machines are able to produce accurate angles due to their intelligent technology and meticulous programming. The CNC system enables workers to input the angle and size they prefer into the machine. Then, it uses hydraulic power to bend the sheet metal just so. This ensures that each bend is precise and consistent, as well as ensuring that the end products will be high quality.

Bending of metal stronger and faster with the help of CNC press brake bending technology The machine can also bend metal sheets fast and with virtually no waste. It’s what helps metalworking companies work better and save time. It also lowers expenses due to wasted materials, making CNC press brake machines an excellent investment for businesses.

There are several reasons to use CNC press brake machines in metalcrafft work. One major reason is that it is easy to produce complex bends and shapes. The machine is able to do this, because of its precise programming and control. Additionally, cnc press brake machines can handle varied materials and thicknesses. This gives you a broader range of metalworking projects.

CNC press brake machines can be used in a wide range of businesses. They can produce custom sheet metal parts for cars or parts for construction projects. Their capacity of bending metal to various angles and shapes is what makes them a valuable tool for any metalworking task.

The better the technology, the better the CNC press brake machines. And new features and ideas are constantly being added, to make them work better, be more accurate, and easier to use. With cutting edge CNC press brake technology from JUGAO, sheet metal fabrication has become faster, more precision metalwork can happen, this results in less wastage, and ultimately products that adhere to industry standards.