Ever just stopped once to appreciate the geometries of metal parts? How they are made is quite interesting, right? Thanks to the magic of CNC brake technology metal sheet can have this shape.

In this article we will look in more detail at CNC brake technology. CNC - Computer Numerical Control; basically means the computers control what happens with the machines. The brake, a machine that is imperative in this process, serves its purpose as you can see metal sheets be bent with exact precision. CNC Department: We use his technology in the CNC brake such that each of these sheets is bent with perfect accuracy, and are properly controlled by how bendy we want them to be.

The machining of metal parts is a complex task and includes many difficult steps. Producing these parts with precision and sustainability takes a lot of time for someone who has experience in shaping them properly. And this is exactly how the CNC braking technology comes into play, changing our perspective of fabricating metal parts.

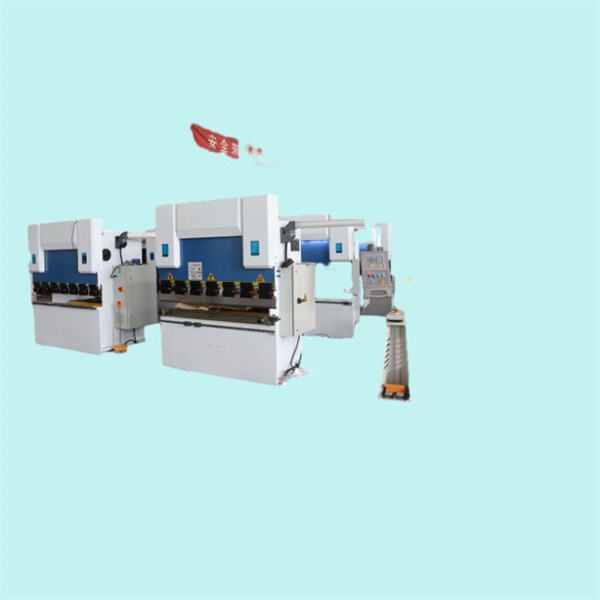

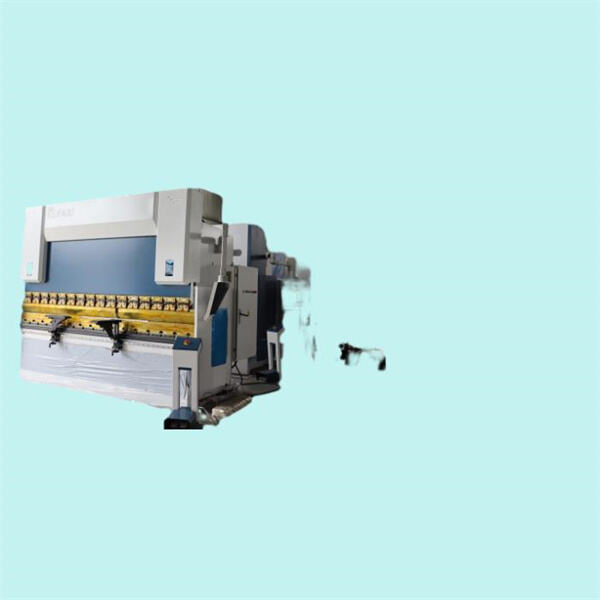

Using CNC presses these metal roller procedures turned out to be progressively more proficient. They can make the exact same bend over and over with pinpoint accuracy which will drive down production times, labor costs. In addition, they ensure that the parts are made to correct configurations and sizes by excluding any mistakes which can happen through manual metal bending techniques.

Next up, advanced software technology to improve CNC brake performance. If you are interested in using the best digital software to improve machine control, CNC brake technology is for you. You can take your machine to the next level and improve its accuracy by integrating software into the process.

One example of this can be found with the designing of a part shape, which you would use CAD (Computer-Aided Design) software in order to do so. After this, you can use CAM (Computer-Aided Manufacturing) software to create a program that will automate the CNC brake process. This software allows you to control complicated variables like the bend angle and bend depth, material length-, or which way it's bending.

Truly, the effect of CNC brake technology on the metal-forming backbone is amazing. It completely changes the paradigm of how we produce parts, allowing us to manufacture complex metal components in an incredibly short space of time. The difficult days of considerable time that workers had to spend in the manual cutting and bending metal in endless hours, are left behind. This is very beneficial as parts can be produced more efficiently, accurately and quickly making it possible for manufacturers to produce a large number of components while maintaining quality.

aware importance after-sales service RD innovation. provide array after-sales solutions such Cnc brakeg after-sales press brakes, various products. same time, continue invest research development, support improvements products using latest technologies meet evolving needs customers help customers maintain leading position marketplace.

Rolling Machines Cnc brake metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Cnc brake capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Quality Builds Cnc brake: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.