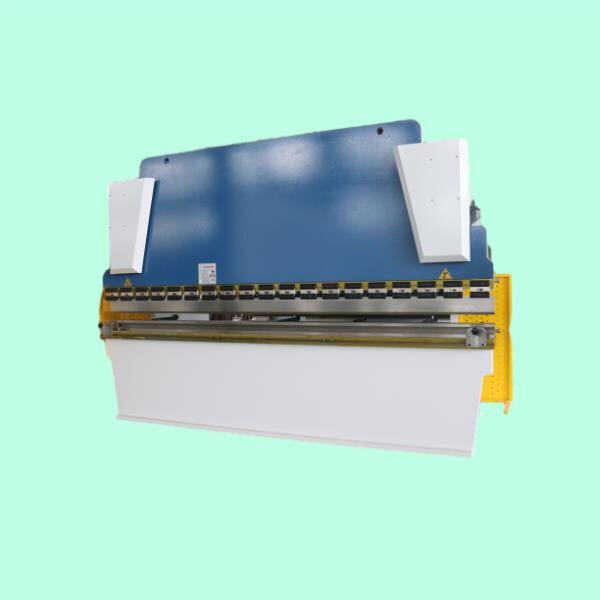

Operating a 100 ton press brake might seem to be overwhelming at first. With a little guidance and practice, however, you will also be able to use this powerful machine. Press brakes are employed in factories to bend and shape metal. A 60t press brake, such as the ones from JUGAO, is a fantastic piece of machinery that saves a lot of time and effort.

An interesting thing about the 60 ton press brake is that you can bend sheets of metals up to 6 feet long and 1/4 inch thick. This means it has a wide range of metal projects it can perform, from small pieces to large ones. Special shapes and designs can be easily formed by varying the bend angle and depth for the outside and inside bends. The bending is always right since the hydraulic system ensures that it is so.

Now just to be competitive, you’ll have to understand a 60 ton press brake in different way. They need to be instructed on how to use the machine safely and properly by rules and regulations and steps. With the proper understanding of how to operate a press brake, workers can produce high-quality parts for a wide range of industries.

Speeding Up Production with a 60 Ton Press Brake If you want to make your production faster using a 60 ton press brake, you need to start with good planning. Workers can ensure each bend is exact by sketching out detailed blueprints. The right tools and methods, such as tooling and back gauges, advance the bending process and reduce waste.

There are a lot of different things you can do with a 1000 ton press brake in metalworking. From straightforward bends to more complex forms, it can handle a diverse array of tasks with ease. Workers can create different bends and angles to their specifications by swapping out tools and adjusting settings.

60 The press brake allows companies to save time and money by improving the speed and precision of work. Faster production, better parts Companies can better meet customer needs and compete in the market.