Single phase press brakes are unique tools in the metal bending and shaping industry. They are extremely renounced for wishing requirements of low pressure mould cleaning to high hydraulics pressing These C Type Power Press have been most usually found with much eco friendly Option With Pro ECO Model. In this article, we will know about single phase press brakes, their advantages and how to use them for creating varied metal products.

Single phase press brakes can be phenomenally efficient for smaller factories. The most notable benefit is that they are very convenient to use. There is a low barrier to entry in terms of operating these machines, with novices or first-time press brake operators easily learning how to use them. The latter are also light; therefore, they can be easily transported from one room to the other which is advantageous in huge factory environment.

Single phase press brakes are also ideal for the production of small parts. This is particularly the case for small factories, where producing large and complex component parts would be unnecessary. So as a result, they are good at making smaller things in larger amounts with more efficiency. On top of that fact, another reason single phase press brakes are great for small businesses because they run at a cheaper cost than other types so you will never over pay from the price and still get quality equipment.

There are a few key points to remember in order to optimize safety and efficiency when using our single phase press brakes. The first thing is to avoid using the wrong tools for the job. The tools are designed to work together since they are the parts of the machine that interact with and form (bend) metal sheets. Incorrect tools can not only spoil the machine, but also lead to the fact that metal is bent in an incorrect way - this is a waste of money and time.

Not only that, the metal plate also needs to be fixed in grip effectively (but most properly you should do this before the bending operation). This is crucial in aiding the positioning and preventing movement of metal while being formed. Careful adherence to the manufacturer's instructions is also very important. This will protect you while on the device and it gives life to the machine so we can still use this effectively.

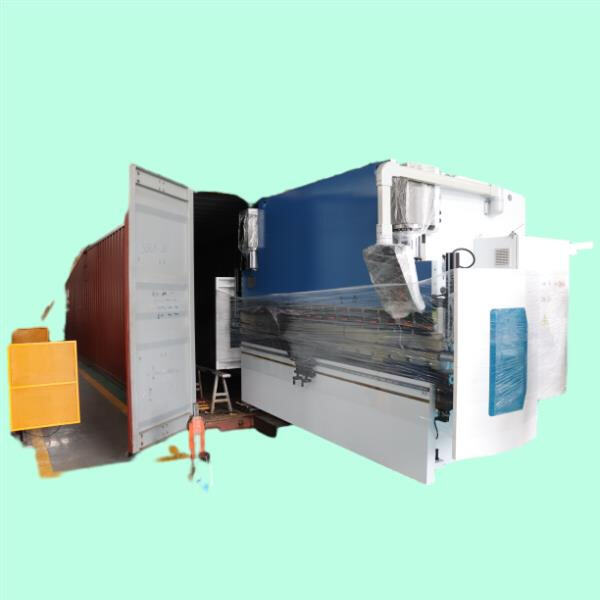

The single phase press brakes are of the following types and they include manual, hydraulic, etc. There are manual press brakes that operate by hand, and there are also hydraulic press brakes which utilize special hydraulic pressure for this purpose. This is the reason it can make accurate bends for utilization which requires accuracy, hydraulic press brakes are normally better.

One of the greatest inventions to aid a worker in working metal is single phase press brakes. This is because they are simple to use, thus helping workers bend sheets of metals into various shapes for the needs in their projects. On the other hand, they are good for small business because it is cheaper than any kinds of press brakes so that you can purchase a machine but keep some capital to make your industry bigger.

Single phase press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

Single phase press brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Quality Single phase press brake Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.

Single phase press brake accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.