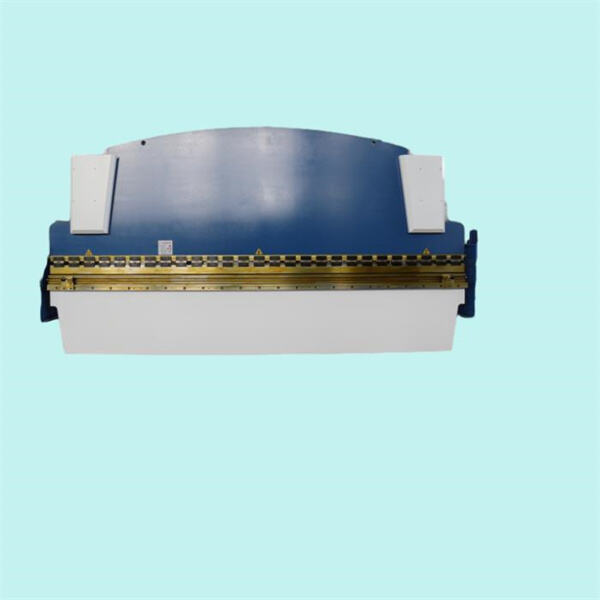

Are you in need of a robust bending machine that can cater for all of your tasks and which has been space constricted? In this situation, a JUGAO tandem press brake may be a feasible solution. A compact press brake can quickly bend any material along the same structure that one would find in most machines, but it has a very high yield use of the total square footage. That is the reason why it is ideal for small to medium work stations or any other area that has been space limited. A small press brake might be just the ticket for the gains you desire to make in the efficiency of the entire manufacturing processes.

Compact press brakes are incredibly useful as they can bend your tool in a fraction of the time to save weeks on other machines. By the same token, and hardly less than full-size press brakes, they would require power-hungry that is low enough to deliver energy-efficient and cost-effective solutions for the users.

The companies that have strategies to innovate their manufacturing processes and make the best use of a limited resource, need compact Press Brake. It's compact (sounds silly) so it fits in with other devices, making work flow more efficient.

Furthermore the JUGAO tandem press brake machine comprise an enlargement feature in the regions that created the bends easily. Various models available, some come with a CNC (computer numerical control) system to help automate the bending process and hence reduce manual labor as well.

Get The Most Accurate Bending From A Compact Press Brake

If you need more precise shaping then a small press brake, sometimes called a simple or box-and-pan brake will get the job done. These JUGAO brake for press are far more accurate than other bending equipment and ensure that the bends made can be adjusted quickly according to what is required. In addition, a small press brake is able to work on different materials like aluminum or stainless steel and ensure what you want in the end.

In Conclusion

Buying a small press brake might be the right decision for you for all sorts of reasons - whether your job is based on metal work and are using it professionally, own or run industry; Or in simpler terms domestic users of these tools. It gives the freedom to save space, increase productivity as well as quality of your end products. Moreover, you can personalize the device with accessories and that makes it a little more stylish based on your requirements.

So why delay? If you are indeed driven to mechanize your manufacturing feat and provide higher quality products, a compact press brake will be of great help. The perfect win-win for your bottom line.

A streamlined press brake might be exactly what you need if your goal is to make improvements in the way that manufacturing processes are carried out. This effectiveness allows for a reduction in production times, higher productivity and to produce high-quality finished goods.

The healthy press brake also considers the compact category that is normally small size companies. As a folding back story, it is powerful enough to manage almost all of your bending duties but small an the space where they adapt. Plus, there are a range of compatible accessories on offer which enable you to customize it for tailor-made operational requirements.

A large number of benefits comes with using compact press brakes in your manufacturing and production operations. The most obvious benefit is they are extremely versatile, being able to produce anything from simple bends to complex shapes. They are also very accurate which ensures that your products meet the exact product dimensions.

One of the best parts about compact press brakes is their efficiency since they can bend your tool in less time to save weeks on alternative machines. At the same time, just as less in size to full-time press brakes (./.), they will need power-consuming that is reduced enough of providing energy-efficient and cost-effective results for users.

For the companies wanted to optimize their manufacturing processes and get best out of a limited resource, having a compact Press Brake will be blessing. Compact-fits in with other devices, streamlining processes.

In addition they consist of progress features which created the bending very easy. A number of models are available, some with a CNC (computer numerical control) system to automate the bending process and reducing manual labor as well.

How A Compact Press Brake Provides For Accurate Bending

If molding and bending is required to be more specific in shape then a compact press brake, also sometimes called a simple or small shop press brake will probably do the job for you. These machines have increased tremendously in accuracy when compared to other bending equipment, and facilitate quick adjustments as per the needs of bends. On top of that, a small press brake can process multiple materials such as aluminum or stainless steel to guarantee the end results are according with your requirements.

There are many reasons why purchasing a small press brake could be the best decision for you - both if you work with metal as a professional, running or owning your own business; and simples domestic users of these tools. This allows you to save space, improve productivity and increase the quality of your end products. In addition, you can customize the machine with accessories that are most appropriate for your needs and this gives it a bit more flare.

So why delay? If you are on the lookout to automate your manufacturing operations and deliver premium-grade products, make sure to get yourself a compact press brake today. This is a win-win for your bottom line.

Compact press brake brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market Compact press brake using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

recognize significance RD Compact press brake. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

Compact press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.