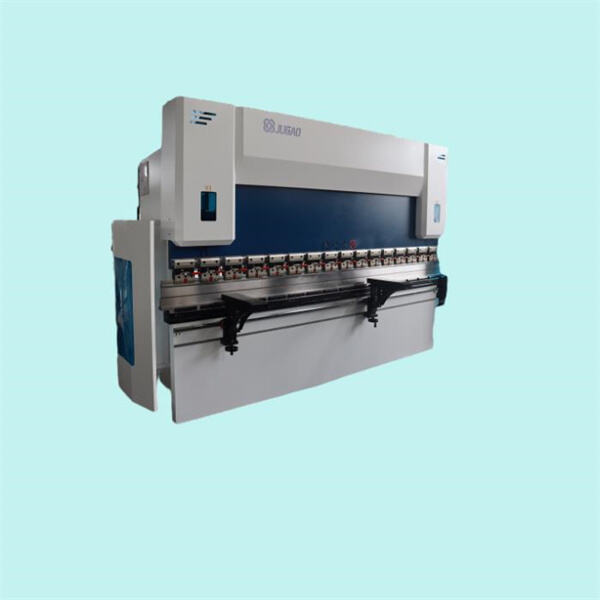

Friend if you want to know how metal things become all shapes, sizes and items then here is your answer The CNC press brake bending machine is one of the vital tools created and used in achieving this. Machine - The machine is one-of-a- kind and this reduces metal press working time significantly due to processing of larger number of sheet metals suitable for bending and reshaping at a given period. So today we will be discussing the functions of a CNC press brake bending machine with more depth for you.

One characteristic of the CNC press brake bending machine that is hard to beat are with regard to its capacity for immeasurable accuracy and efficiency in metal sheet bending. It is, however, achievable by the programming of the machine and creating instructions on which way to bend. These instructions are painstakingly written on a computer and saved to memory card. The operator subsequently inserts this memory card into the machine and starts the bending procedure that leads to a precise and swift outcome.

The arrival of the CNC press brake bending machine has transformed and simplified various procedures in the Steel fabrication industry. Before this ground-breaking innovation, metal fabrication had been a backbreaking manual job that was involves many mistakes and required time. It has raised bar of metal object production which allows rarely any leakages, with the scale making possible to fabricate at fast rate by CNC press brake. This technological improvement now allows metal fabrication organizations to fulfill customer requirements more efficiently and maintain high quality standards across departments.

Safety priorities in the designing of how to improve productivity and protect operator, so siftware it self bring several safety option like guards or sensors.... When in operation, the machine is designed to have guards protecting it and preventing an operator from accessing a bending area. In addition, light barriers are used to determine defects already during the bending operation (automatically stopping the machine in this case) that contribute both to avoid accidents and create a safe working environment.

A CNC wood press brake bending machine, with it is capable of doing a large assortment of features rendering it an essential tool for specific metallic twisting jobs. This thing is able to bend metal sheets of various weights in many lengths, and this machine can be very accurate. But we have to recognize the machine limitations like it will neither bend too thick or long sheets of metal. Understanding what the limitations and capabilities are of a CNC press brake bending machine is also important to get maximize use out of it.

Conclusion - The CNC press brake bending machine is for sure the backbone of this metal fabrication industry, highly precise and efficient with an excellent safety protective system. An in-depth understanding of how the machine operates, and through this sensitivity to what it can accomplish (and its limitations), users are able to exploit all that the metal bending application has got going for them.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Cnc press brake bending machine.

Press Brakes known reliability precision Cnc press brake bending machine various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor each machine's quality ensure conforms industry standards. laser cutters rolling pipe bending machines, strive top-notch products ease anxiety customers.respond rapidly Cnc press brake bending machine demands through efficient production supply-chain management. time deliver can reduced week ample inventory. enables rapid equipment purchases competitive advantage.

Cnc press brake bending machine efficiency precision, laser cutting machines handle wide range different materials. Rolling machines, outstanding forming capabilities speedy production meet demands many clients. Pipe bending machines utilized mass production due versatility stability. embody essence latest industrial technology enable manufacturing sector adapt various challenges quickly, precisely high degree flexibility.