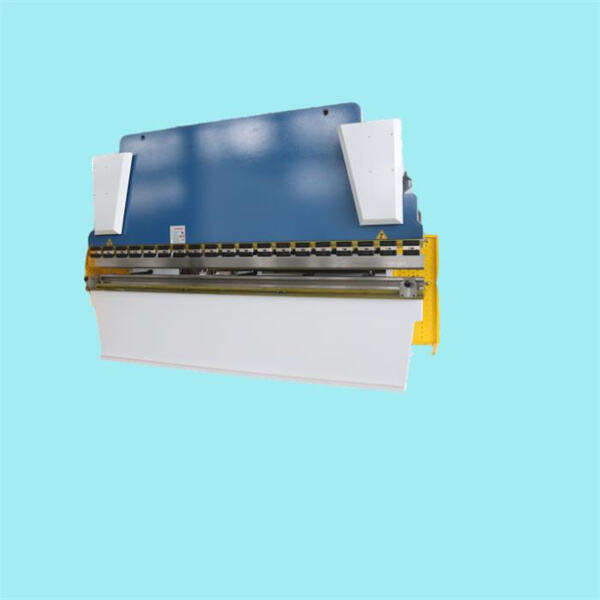

An industrial press brake yields the best level of accuracy when it comes to bending metal. These are precision metal benders that use hydraulic force to bend sheet materials into the desired shape. Correct machine setup and sheet position are critical to achieve the desired bend.

One of the most crucial factors to take into account when choosing an industrial press brake is the thickness and type of metal it will be formed. At least you get a choice between mechanical and hydraulic (the latter is needed with the higher-capacity bending force). This is especially true for hydraulic press brakes, which have always been praised as some of the fastest and most precise bending solutions onthe market.

When it comes to metal bending tasks, efficiency is the key. The industrial press brake configuration is the most critical for productivity. Before Every UseKeep the machine clean and properly maintained to get high performance each time you use it. Moreover, the accurate choice and usage of tools reduce human errors when bending.

Industrial Press Brakes are the latest in technology to bend metal properly and this means, it can be shaped more accurately than human hand. In this method, the hydraulic press brakes help reduce physical stress while bending a metal sheet particularly when there is large thickness. This is useful for manufacturing complex and strong metal shapes

Metal bending in the world of industrial press brakes can be as complicated-construction or large-architectural pieces, to metal art-installations with intricate, straight lines. In addition to this, these devices are furnished for bending a range of metals such as aluminium and stainless steel sheets.

To sum up, the industrial press brakes is an important solution to carry out bending of metal both in terms of precision and efficiency. They can be used to maneuver different types of metal and all shapes. Take the power of an industrial press brake into your own hands today and start making incredible metal works!

Industrial press brake Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

Press brakes ideal Industrial press brake tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

recognize importance after-sales service RD advancement. press brakes, laser cutting machines, rolling machines, pipe bending machines, other products, provide entire range support after sales includes Spanish after-sales service, make sure customers enjoy Industrial press brake experience. same time, continue make investments research development encourage latest technology product development meet ever-changing needs customers, assist customers maintain position market.

Quality Industrial press brake Trust. We a passion sheet metal machines ensure every machine par standards industry. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease customers' worries.Rapid Market Response: leveraging effective supply chain production management, promptly respond market needs. delivery time can cut one week we ample inventory. enables quick equipment acquisitions well as an advantage competition.