How to Select The Right 60 Ton Press Brake for Your Steel Fabrication Business

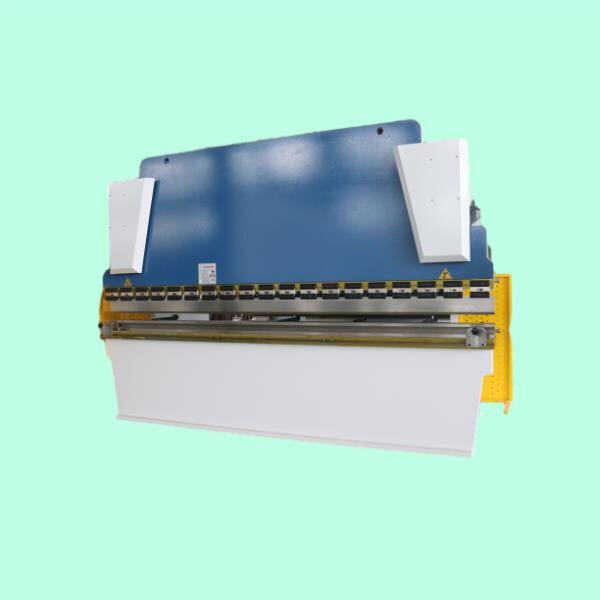

Press Brake is an Important Tool in the Realm of Metal Fabrication While there are many makes and models to choose from, one of the more popular options is the 60 ton press brake. For instance, if you are planning to buy a 60 ton press brake for your metal fabrication business, this is an extensive guide that will help in making the right selection.

Capacity is the first thing you need to look for in a 60 ton press brake. The “ton” in the press brake means how much force they can use to bend the metal. In this application a 60 ton press brake means the machine is able to apply up to 60 tons of pressure, perfect for thicker type materials. On the other hand, if your projects involve thinner metals you may select a press brake with lower capacity.

Another crucial element to consider is the height of press brakes. However, 60 ton press brakes come in all different sizes and you will want to pick the one that fits your materials. It is better to use a compact press brake that occupies less space for lighter materials. Similarly, when working with more substantial materials - a larger press brake is necessary to support the size and weight of your workpieces.

It also comes down to the kind of press brake you are using a 60 ton model. There are really three main kinds of press brakes available on the market: hydraulic, mechanical and pneumatic. Hydraulic press brakes are preferred for their precision and mechanical control, while a more economical option is to go with a mechanical means that requires higher maintenance. Pneumatic press brakes, meanwhile have more simplified applications for the lower price of hydraulic and mechanical versions.

In the world of press brakes, brand does matter also. Branding powerhouses like Trumpf, Amada and Accurpress have left their mark. Factors such as brand, reputation,product quality and customer service should be considered while choosing a product to promote Reviews and suggestions from other metal fabricators can also help you know the best brands out there.

Operating Tips to Keep Everyone Safe and Your Unit Running Great

Understanding how to use a 60 ton press brake is important if you are just entering in the industry and need one. Best Practices to Boost Operational Efficiency

Before pressing: Read your manual properly to completely understand the working procedures and guidelines that are used for preventing damage of press brake.

Put on Appropriate Dress: Before using the press brake, we must wear long-sleeved clothes pants and safety shoes to ensure no risks.

Examine the Machine: Channel a detailed inspection of each component suitable for this press brake, verifying signs of wear or damage and guaranteeing adequate performance.

They simply need to make necessary alignment of the press brake, including settings for back gauge and die opening with respect to material specifications that are being worked upon.

Use Proper Tooling: Use the correct punch and die to get an accurate bend angle and a radius you need for your project so that every time you will have perfect results in sheet metal folding

Speeding Up a 60 Ton Press Brake By Unlocking Versatility

Conclusion:The 60 ton press brake this type model has very extensive uses in the metal fabrication industry, which includes:

Sheet Metal Bending - Best for precise bend of thicker sheet metal sheets.

Angular bending: Used with arrays of tooling to create different angles.

Box Bending - Used to create parts made of metal that look like boxes, often used in fields such as automotive industry and aerospace.

Improved Accurate through Innovative Features

When looking for a 60 ton press brake designed specifically to serve the precision metalworking market, look out for these advanced capabilities that enhance bend accuracy and repeatability:

CNC Control: The application of CNC control technology makes the bending more accurate and errors minimised.

Auto tooling: Automated tool sets allow for fast and easy changes, which are less disruptive to the process of metal pressing.

Precision Material Back Gauge: To obtain the accurate folds in automatic metal folding, it is a nobody but to have precision back gauge that not only acts as an adjustable plate support system but also quickly adjusts automatically during facilitation of loading.

Chapter 3 How to Choose the Right Press Brake for Your Industry

A 60 ton press brake is serious investment for a metal fabrication business. Evaluate the aforementioned factors and make an informed decision in order to comply with your industry needs.

Tonnage: Choose a 60 ton press brake which suits your metal fabrication operations - thick material with powerful capacity.

Press brake type: Choose a press-brake (hydraulic, mechanical or pneumatic) that fits your budget expectations and at the same time meets application requirements / precision standards.

Brand: Reliability and customer service ratings of the brand are required to be high Research online and garner feedback from other professionals in the industry to help you with your decision-making.

100 Ton Press Brake, then this information will be useful to you beach and if your looking for the best 200 ton press brake. During the selection, if you consider about capacity and size. type & brand to decide your best one (also cost vs benefit) withcare of safety protocols, itwill also save lots while exploring many unseen features in this equipment which canbring tons together for elevating your metalworking supports!!

60 ton press brake brakes ideal complex bending operations high pressure accuracy laser cutting machines able deal range different materials efficient high-precision cutting capabilities; Rolling machines, thanks excellent forming capabilities effective production, satisfy needs large variety clients. Needs mass production. Pipe bending machines suitable various pipe processing due flexibility bending dependable performance. essentials industrial technology help manufacturing sector tackle various challenges efficiency, accuracy flexibility.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain 60 ton press brake advantages.

60 ton press brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

60 ton press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.