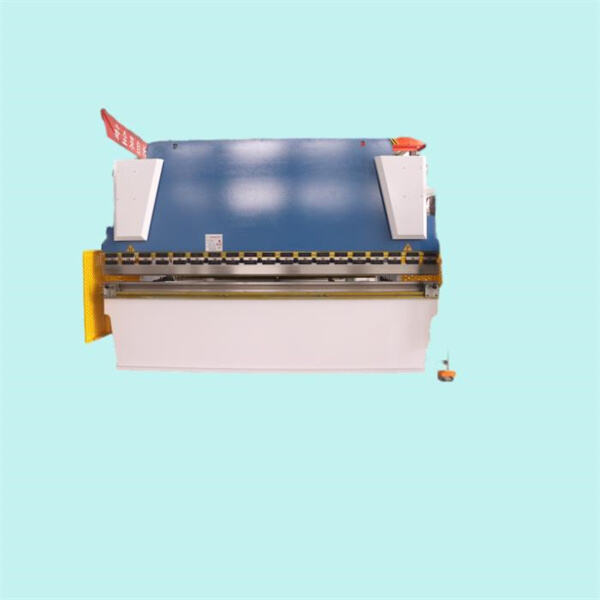

A type of metal master press brake suitable for bending easily and accurately to an angle you require is necessary. This amazing tool makes it possible to fabricate metal in a countless possibilities of shapes and patterns. What is a metal master press brake, and how do they operate?

The productivity of a metal master press brake is the bending and acquisition by many ways and angles metals sheets have. It operates on a system of hydraulics, which is simply using liquid pressure to move things around. When the machine is operated it forces the metal which will bend to a certain point. That means you can make the correct shape to use in your projects.

Finally, one of the greatest capabilities of a metal master press brake is its ability to bend most metals very precisely. This allows you to easily create bends so that each piece fits your grand plan correctly. This is crucial in maintaining the order of all things. Furthermore, this metal master press brake is made out of great materials which also increases longevity and how long the machine can survive in heavy use.

Time is of the essence in the metalwork world, and a right press brake like Metal Master can make your workday easier. It can bend sheet metal fast and exact, to get your projects done faster. This will result in more time, which you can use to start your new projects or secure it away and make the rest of your working day that much better.

No two projects are identical, and with a metal master press brake you can adjust the way that you bend your metal to suit any need. Personalize the speed, angle and pressure to allow you for preferable bend fitting your work. This flexibility is a big win because you can control the bending process based on what exact type of metal and thickness needs to be bent. Additionally, this machine can process different types of metal sheets which provide you a variety for your projects.

Quality Builds Metal master press brake: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

Metal master press brake Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

Press brakes suited bending tasks require high pressure accuracy; Laser cutting machines manage wide range materials efficient high-precision cutting capabilities; Rolling machines, superior forming capabilities Metal master press brake production, can requirements huge number customers. Production requirements mass production; Pipe Bending machines ideal various pipe processing due bending flexibility stable performance. products embody essence modern industrial technology help manufacturing industry adapt various challenges, accurately flexibly.

Metal master press brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.