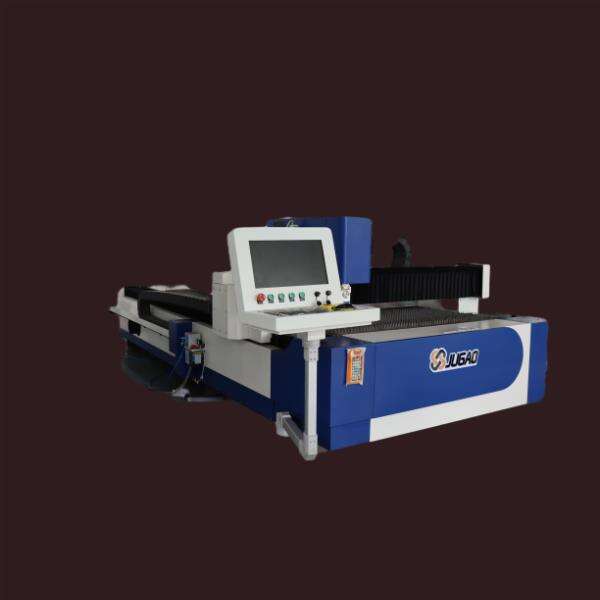

Laser cut machining is a process used to cut products using a laser beam same with JUGAO laser cnc cutting machine. The beam is directed using computer-controlled machines, which makes it a precise and method efficient of. This technology advanced several advantages over traditional methods, making it a popular choice for a variety of applications.

Laser cut machining offers many advantages, including precision, speed, and versatility. The laser beam can accurately cut shapes that are complex patterns with ease. This ability to achieve precision is especially useful in industries such as engineering, aerospace, and devices that are medical accuracy is key.

Another benefit of JUGAO laser cut machining is its speed. Laser beams can cut materials at high speeds, making it an process efficient. This speed is beneficial in industries where large quantities of materials require to rapidly be cut.

Laser slice machining is also very versatile, as it can cut a range wide of, such as metals, plastics, and wood. It is made by this flexibility useful in a variety of industries, including automotive, electronics, and construction.

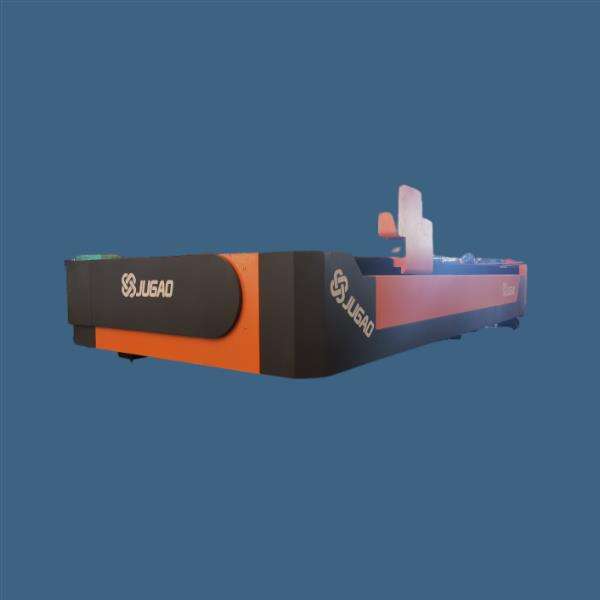

The innovation in laser cut machining has led to developments in the technology just like the JUGAO aluminium laser cutting. For example, the use of fiber lasers has made the process even more accurate and efficient. These lasers are smaller and more energy-efficient than traditional CO2 lasers, resulting in less waste and lower energy costs.

Another innovation in laser cut machining is the integration of robotics. This allows for even greater efficiency and precision, as robots can manipulate materials and direct the laser beam with great accuracy. The use of robotics also reduces the risk of injury to workers by minimizing their experience of the laser beam.

While JUGAO laser cut machining is an technology advanced it also brings potential safety concerns. The laser beam can cause injury serious not handled properly. It is important to take precautions, such as wearing eyewear protective limiting exposure to the laser beam.

Proper training is also essential for those who operate laser cut machining equipment. Training should cover the use safe of equipment, as well as emergency procedures in the big event of an accident.

The material to be cut is placed on a table or platform beneath the laser beam to use laser cut machining this is same with JUGAO laser cnc machine. The operator then works on the computer to direct the laser beam across the material, cutting it with great precision.

The operator must be mindful of the charged power and speed of the laser beam, as well as the material being cut. Different materials require different levels of power and speed to achieve results that are optimal.

Press Brakes known reliability precision Laser cut machining various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

Laser cut machining Builds Trust: Dedicated sheet metal machinery rigorously monitor quality control ensure each machine line industry standards. work hard offer best products clients. From laser cutters press brakes pipe benders rolling, rolling, rolling machines.react quickly market demand leveraging effective supply chain production management. plenty inventory, delivery time reduced week. allows prompt equipment acquisition competitive advantage market.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Laser cut machining.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle Laser cut machining materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.