Press brake bending is one of the most common and effective techniques used for molding sheet metal. This method used in machining also work on many industries of any factories or manufacturing company for the different kinds of metal product such as doors, windows and even cars. A press brake is a machine made for bending things precisely this way. This machine is pressurized to fold the metal segments in our desired shapes.

One fact for you: bending metal is never going to be as easy. (There will be practice involved as well, but it does take feel and an eye for detail) Every sheet metal piece is different; the press brake operator should know when to fold hard or soft... what angle to bend the material. The specifics of each wire, and sheet vary greatly with the exception being metal thickness. The experienced press brake operator does that,himself and usually with knowledge of the typical differences for his machine.

Always wear safety gearWhen dealing with heavy machinery, safety is the number one priority. Before applying the method of working into press brake, you must that you put on a protection to reduce chances accidents and injury your safety.

Free Up Some Room: Keep your workspace clean and organized. if you know everything has its place, so much the better to help maintain a workflow The operator can easily locate tooled components and safely use them on a clean bench reducing both search time for the right hardware, as well as accidents.

Bend Radius: the tightest curvature that can be made without fracture (breaking) of metal. Step 7: THE BEND RADIUSThe Bend Radius is important because when you bend a curve into an FDM part there are limits and knowing those values will prevent your parts from being damaged.

K-factor is a value that can help calculate how the metal will be thick while bending it in machine and already set up for bend. The K-factor will be the same to a big dawg difference, at least then operator might adjust accordingly in this situationogrphics achieved!

Step #5: Get a Backing Bar A backing bar is essentially nothing more than just some piece of metal you plop behind the bend. The extra reinforcement stops the metal sheet from deforming and provides some structure. This is extremely helpful particularly when bending thin metal sheets since they can easily be distorted.

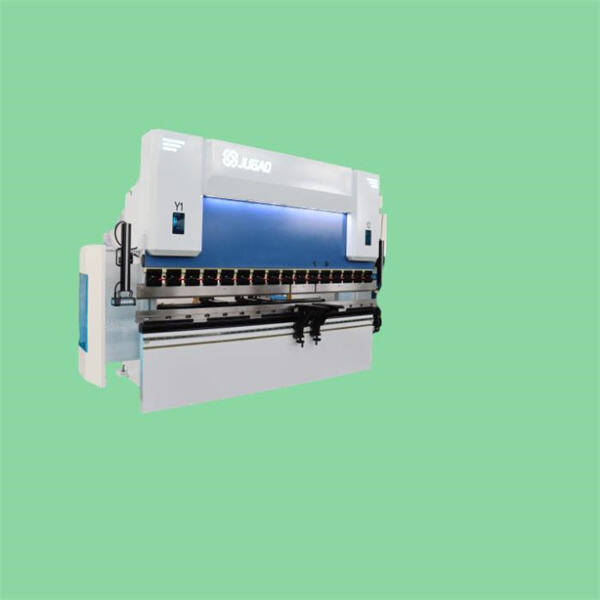

know importance service sales RD Press brake bending. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Press brakes suitable complicated bending processes due pressure precision laser cutting machines able manage wide range materials because precise precise cutting capabilities. Rolling machines, with excellent Press brake bending capabilities efficient production, satisfy requirements huge variety customers. Pipe bending machines utilized mass production adaptability stability. machines embody essence latest industrial technology manufacturing industry respond various challenges efficiently precision, speed flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Press brake bending production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Press Press brake bending renowned efficiency accuracy used many metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting fulfill requirements complex patterns; Rolling Machines specialized forming metal sheets ensure top quality production. Pipe Bending Machines offers flexible pipe bend solutions. product line focuses efficiency, precision, stability help customers improve production efficiency product quality.