Ever tried hammering metal into shape with your own hands? It's tough, right? What if I was to say there a special savior tool that makes this all so easy? Hydraulic Metal Brake Press to the Rescue! Its name might seem complex, however the machine is easy to use. Read on to find out more about how it operates, and what makes them so revolutionary for those in the metal working industry.

Using a hydraulic metal brake pressWhen using the equipment of hydraulics, so you need is on break power(Language) Now, what does that mean? This is sort of working your metal like a liquid - oil, for instanceQRSTUV QW Itiers it easier to shape. On the device, when you push a button or pedal, liquid passes through tubes and draws into pistons. This is the piston which moves and it should be that movement which allows the press to do its job.

So benefits of a hydraulic brake press. For starters, it's a lot faster than trying to hand-form sheet metal. Believe me you really don't want to do that! Not only that but since the press is hydraulic, it's a lot more powerful than some of the tools you might use. This in turn allows you to work with heavier and more robust pieces of metal.

But that's not all! The beauty of the hydraulic metal brake press, is in likening you to a quicker pace without sacrificing quality. Not only is the machine doing most of the work for you, - so what could take a long time with manual bending can be done rapidly on this machineenerative as well. The press is also very accurate, so you can be sure that each piece will come out exactly the same every time.

In this series, we will examine how hydraulic systems managed to bring metalworking what I consider its most elevated form. Hydraulic Thats Science Class Right There How They Bend Metal They offer a level of control and power unmatched by traditional tools, enabling you to bend force in ways unachievable otherwise. This creates a plethora of new opportunities when designing elaborate metal shapes and folds.

Wondering what you can make from a hydraulic brake press? The options are almost endless! This flexibility makes them suitable for a wide selection of metal forms and structures. Whether you are dreaming of brackets, boxes and more complex machinery parts,if u can think it up like in your dream then the answer is yes its possible using a hydaralic metal brake press.

Well, there you have is: the essentials of the hydraulic metal brake press. It may appear complicated, but it is just an indispensable gadget for anyone working with metal. If you are a professional metalworker or just like doing your own work at home then the DEKO DCSLP05, 20V Li-Ion Cordless Metal Cutting Circular Saw is an excellent machine to check out. Who knows? You might even discover that it changes the way you think about metalworking to begin with!

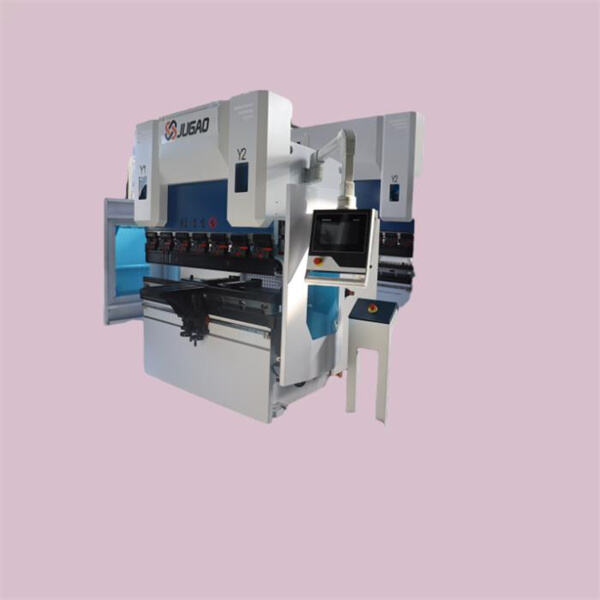

Press Brakes known reliability precision Hydraulic metal brake press various metal sheet processing; Laser Cutting Machines perform high-speed, high-precision cutting satisfy most complex requirements pattern design; Rolling Machines specialized forming metal sheets ensure high-quality production; Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability enhance production efficiency quality products.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Hydraulic metal brake press.

Press brakes ideal Hydraulic metal brake press tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective Hydraulic metal brake press production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.