Ever wondered how people bend metal into new and different shapes? It might be hard, but there are tools available that can ease the job. One of the most interesting tools is a press brake laser line. It is very useful because high accuracy bends can be produced in metal sheets by Metal workers using this machine. The light that comprises the laser line is as bright as a rainbow and indicates exactly where metal will bend. It reflects very powerful line of light on the metal sheet that with no doubt shows where bending will start and end. This helps people know what they should do.

There are a few good reasons to use the laser line on your press brake. The first one is, it allows the metal workers to be exact with accuracy while bending their metals. Metalworking is one of these areas where accuracy is very important in nature as even a small mistake can make the whole piece unusable. They could only abend metal sheets without a laser line, and there is the risk of making an error. Even a small mistake will spoil the metal piece. In other words, they can only bumble through it again from scratch - more time, more money wasted. Using a press brake laser line, will help the worker to assure that bend is exactly what it should be providing value in avoiding those expensive mistakes.

Another important reason to consider press brake laser line is that it saves time. With the laser line, metal workers can proceed without measuring and marking by hand on a piece of thin sheet. This can be very time consuming and particularly challenging with larger panels. It can also be very tiring! But with the laser line laid down, they are free to identify their sheet of metal and start right into bending. These make the booking process smoother, and quicker.

A press brake laser line can also significantly reduce the burden of metalworking on workers. They are able to work more quickly and concentrate on the essential elements of their job when they have a laser line assisting them. Not having to re-measure it, or have it perfectly square on the sheet. No, instead they can simply focus on the act of bending metal - which is much faster and easier when a laser line tells them where you need that bend. This means that they can finish their task in a calm manner, without focusing on submitting it to someone ordinary!

As you know, one of the crucial aspects in achieving bends other than twist angles. Press Brake Laser Line - A laser line makes it easier for the workers to know where exactly metal will bend in a press brake. This way they are capable of lining themselves up with the angle in which they desire. If the workers do not have a laser line, it is difficult and wasteful to bend metal at exactly the right angle. Laser line accuracy: This means it is bent correctly each time, better quality of the work

In general, a press brake laser line enables workers to complete their jobs more efficiently and swiftly. This speeds up the most time-consuming part of our job and allows us to avoid mistakes, so we can finish more projects in less elapsed time. With the laser line they can be precise and accurate, which is crucial in metal work. This can be time-consuming and sometimes even cause a margin of error if applied manually without the laser line. This first-class feature allows them to gain more flexibility in the way they work, as well better bending quality each and every time thanks to press brake laser line.

Quality Builds Press brake laser line: Dedicated sheet metal machinery meticulously supervise each machine's quality ensure it line industry standards. strive provide highest quality products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Rapid Market Response: leveraging efficient production supply chain management, swiftly meet market demands. With large inventory, delivery times reduced one week, allows rapid equipment acquisition market advantage.

recognize significance RD Press brake laser line. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.

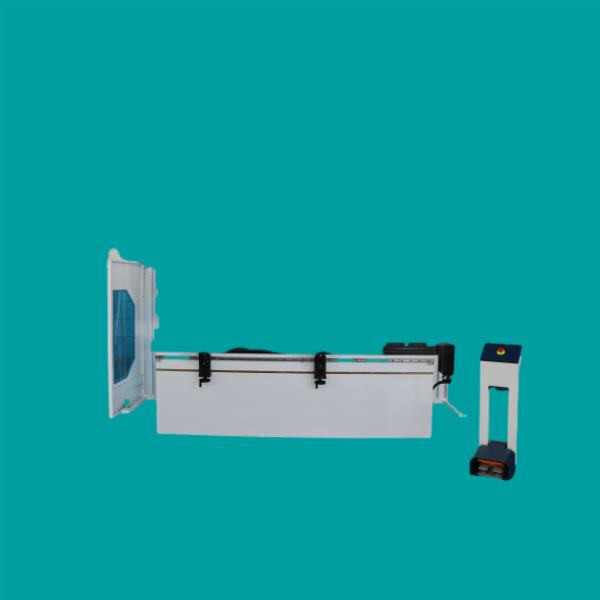

Press brake laser line Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

Press brakes suitable bending complex operations due high pressure precision; Laser cutting machines manage wide range materials thanks powerful high-precision cutting capabilities; Press brake laser line, thanks their exceptional forming capabilities efficient production, satisfy needs large variety clients. Pipe bending machines utilized mass production due flexibility stability. machines core latest industrial technology assist manufacturing industry meet challenges today efficiently quickly, precisely high degree flexibility.