When you are working with metal, you can do a lot with press brake machines. A press brake machine is used to bend metal sheets into different shapes. You need to understand how press brake machine operates and how you can use it safely.

Press brake machines operate by pressing a sheet of metal between a punch and a die to form it into a predetermined shape. The calculator will need to input the correct measurements into the machine’s computer in order to bend the metal properly. The metal sheet is placed on the die, and a punch descends, bending the material to the desired angle. To avoid injury, be sure to follow the machine’s instructions diligently.

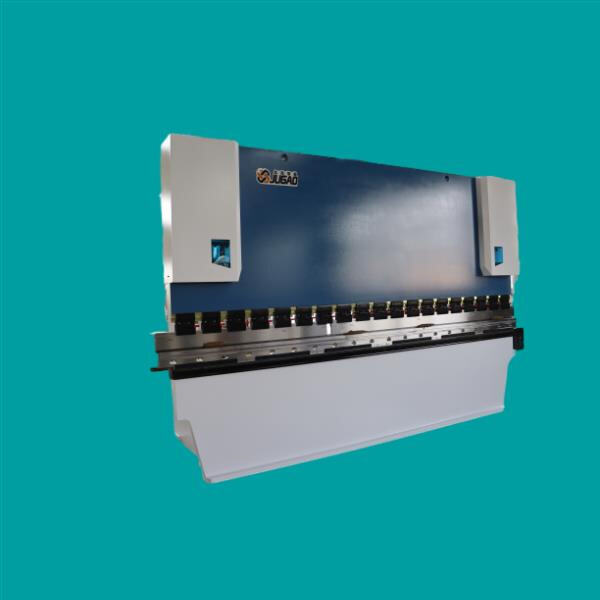

Precision press brake machines allow workers to bend metal sheets with greater accuracy. Employees use these machines to make accurate bends, which cuts down on errors and saves material. JUGAO precision machines are built to help workers become faster and more precise in metalworking.

When selecting a press brake machine, consider the length and thickness of the metal sheets you will be working with. JUGAO had kinds of press brake machine to meet different metal requirements. Doesn’t matter if you would like to handle thin or thick metal sheet we have a machine for you.

Modern press brake technology makes it faster and easier for employees to bend metal sheets. JUGAO'S high-end machines are equipped with fast clamping systems and manual, automatic or programmable bending. These features enable workers to complete tasks faster and with greater accuracy.

Operators should observe safety rules and be aware of all precautions so as to prevent accidents when using press brake machines. Workers also should be using safety gear, such as gloves and goggles. The work place should be clean and tidy to avoid accidents. The machines also need regular maintenance to work safely. Workers should heed the manufacturer’s maintenance recommendations.