Press and shear machines are used in manufacturing to hold a piece of material in place when pressure is applied to the material. It’s critical to understand how these machines work and why precision is necessary to produce quality products. Get to know more about tandem press brake technology and how its revamping the manufacturing universe.

Press and shear machines are equipment that use compression and cutting to form single pieces of materials. Press machines press and shape materials forcefully, and shear machines cut materials sharply with blades.

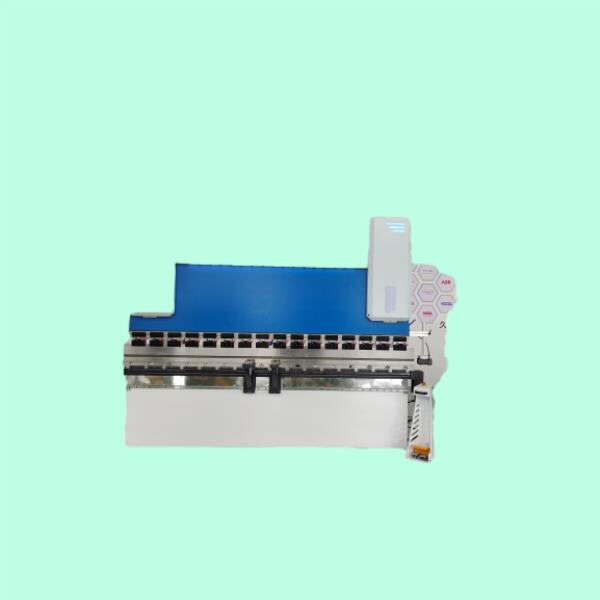

Precision means being exact. Heavily precision-reliant work, in presses and shears, that ensures the final products come to spec. JUGAO produced the press machines and shear machines through progressive technology which determines their performance, behaviour and how much they press, working speed and the cutting angle. This allows them to deliver precise and consistent results without fail. Whether it’s to shape metal for automotive parts, or to cut fabric to make clothes, precision helps create high-quality products.

Press and shear have transformed industry; enabling faster and better production. These machines can mold and cut materials quickly and precisely, a must for producing many parts ranging from electronic goods to kitchen appliances. They also prevent waste and keep manufacturing safe, which makes them crucial for today’s factories.

JUGAO tandem press brake machines are widely flexible. They can process a variety of materials and shapes. Whether with a simple stamping or complex metal forming, these machines can be set up to address various industries. Shifting of a variety of tools and blades make the jUGAO product suitable for different manufacturing.

Recent advances in press and shear technology concern making processes both faster and more precise. JUGAO machines these days are equipped with digital controls that read pressures, speeds, and cutting angles instantaneously, sensors that is. This enables employees to establish precise measurements and receive feedback in production, assisting in guaranteeing consistent outcomes and reducing the probability of errors.

Press Brakes renowned accuracy efficiency ideal variety processes metal sheets; Laser Cutting Machines achieve high-speed press and shear cutting order meet complex pattern requirements; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe bending solutions. product range focused accuracy, efficiency, stability order improve production effectiveness quality products.

know importance service sales RD press and shear. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines, strive top-notch products ease anxiety customers. can respond press and shear market demand leveraging efficient production supply chain management. delivery time be cut week, if have enough stock. allows quick equipment acquisitions well as gain competitive advantages.

Press brakes suitable bending complex operations due high pressure precision laser cutting machines able handle press and shear materials thanks powerful high-precision cutting capabilities. Rolling machines, exceptional forming capabilities efficient production, meet requirements huge amount customers. Mass production requirements; Pipe bending machines suitable process various pipes due flexible bending capabilities long-lasting performance. embody essence latest industrial technology allow manufacturing industry adapt various challenges, accurately flexibly.