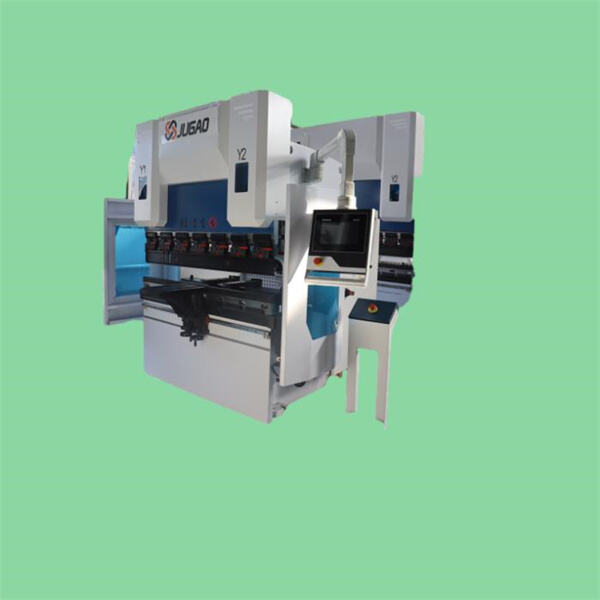

If you’d like to work with metal, it’s useful to know how to use a hydraulic press brakes. A hydraulic press brake is a machine tool for bending, shaping, and cutting metal sheets. The device relies on a hydraulic cylinder to press onto the metal. This aid to bending metal makes the action very precise and fast.

In order to safely use a 350 ton hydraulic press, there are safety rules provided by the maker that should be followed by all. Use the machine with the appropriate safety gear, gloves and safety glasses, for example. Keep your hands and fingers away from the bending space to avoid injury. Before switch on the machine, please make sure your metalsheet is still on two on both side or the metal sheet can’t be aligned on the two edges, or don’t be bent.

There are some advantages of using a hydraulic press brake. A primary advantage is that it allows metal sheets to be bent in complex and accurate patterns. That’s crucial when manufacturing products of precise size and shape. In addition, hydraulic press brakes operate fast, and can mean you get more done in a metal workshop.

Some important matters to consider when finding the correct hydraulic press brake for you 1. Start by thinking about how much bending muscle you will want in your projects. Various press brakes are able to bend different thicknesses of metal, so select one that can bend the metal you will be working with. Other factors to consider are the machine's size and the space in your workshop. Make certain the press brake is going to fit well in yours area.

Troubleshooting a Hydraulic Press Brake If you are having troubles with your hydraulic press brake, then you will be glad to know that you are in the right place. If the machine isn’t bending metal correctly, the hydraulic system might be an issue. Make sure the hydraulic fluid levels are where they’re supposed to be, also look for any leaks or damage in the hoses. It’s also important to clean and maintain the machine periodically to prevent dirt or residue from causing any problems.