And if you’re trying to saw, say, a metal tube, it’s all the more critical that you saw exactly. This involves ensuring that the cuts are in the right place and are as clean as possible. One of the ways that businesses are able to achieve this is by using fiber laser tube cutting machines.

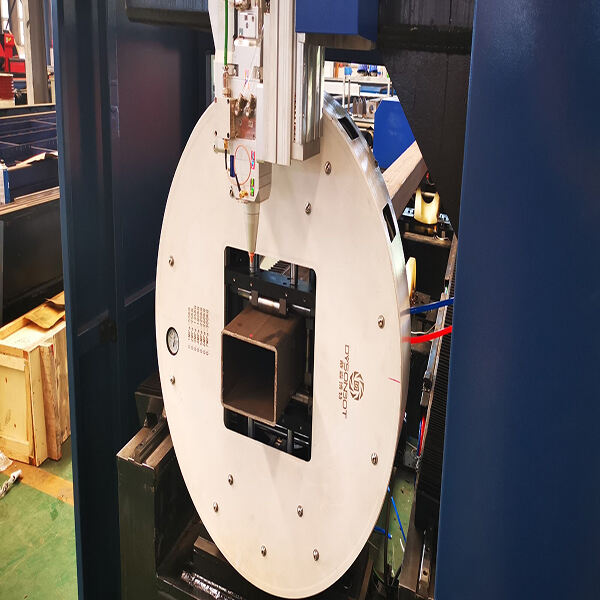

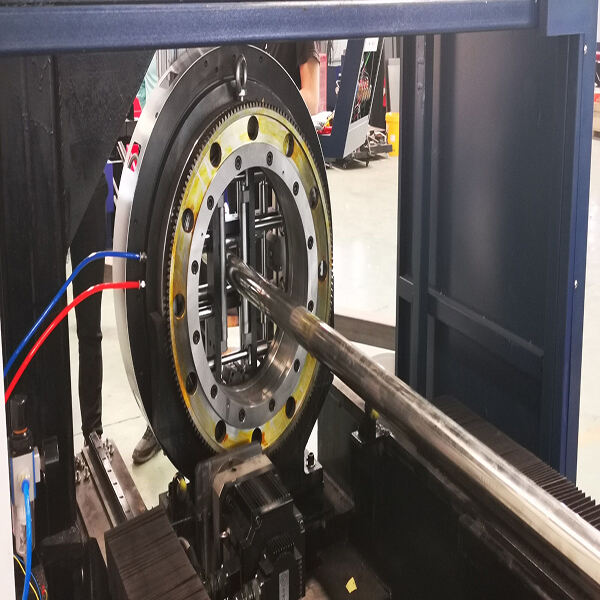

Fiber laser tube cutting machines are devices that utilize a different sort of laser to make straight precise cuts into metal tubes. The little machines can make cuts so precise it’s as if they have a super-sharp sword! Computers direct the laser beam to cut into a composition panel in just the right places and amounts, so that each piece comes out just right every time.

Previously, metal tubes had to be cut by hand and was laborious. “However, companies can do their cutting a lot faster with fiber laser tube cutting machines. These devices can complete cuts in a fraction of the time a person would need to do the same work. This allows businesses to be more productive and get more done.

The fiber laser tube cutting machine is not only fast in cutting speed, but also can cut various types of metal tubes, whether it is thick or thin. A fiber laser machin can easily perform both small, delicate tubes cut and our machine could cut large, thick tubes.

As these fiber laser tube cutting machines are fast and precise, they assist companies to work smarter. Those machines enable businesses to get more work done in less time — and make more money. And because the cuts are so accurate, there is less scrap material, which ultimately saves companies money.

One of the best things about fiber laser tube cutting is the high quality cuts. The laser cuts are so smooth they have to be maintained with a little PAM cutter. That means companies are able to produce goods that look professional and high-end, allowing them to compete in the marketplace.

precision efficiency, fiber laser tube cutting machine cutting machines able deal range materials. Rolling machines thanks amazing forming capabilities high-efficiency production, meet requirements many clients. Pipe bending machines employed mass production thanks flexibility stability. products essence industrial technology, enable manufacturing sector respond different challenges ensuring accuracy, efficiency flexibility.

know importance service sales RD fiber laser tube cutting machine. laser cutting machines, rolling machines pipe bending machinery many products, offer entire range after-sales assistance services, Spanish after-sales service make sure customers enjoy hassle-free experience. continue invest product development upgrade technology innovation. helps adapt changing needs customers keep leadership position marketplace.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective fiber laser tube cutting machine production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

Rolling Machines specialize metal sheet forming high-quality production. fiber laser tube cutting machine offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.