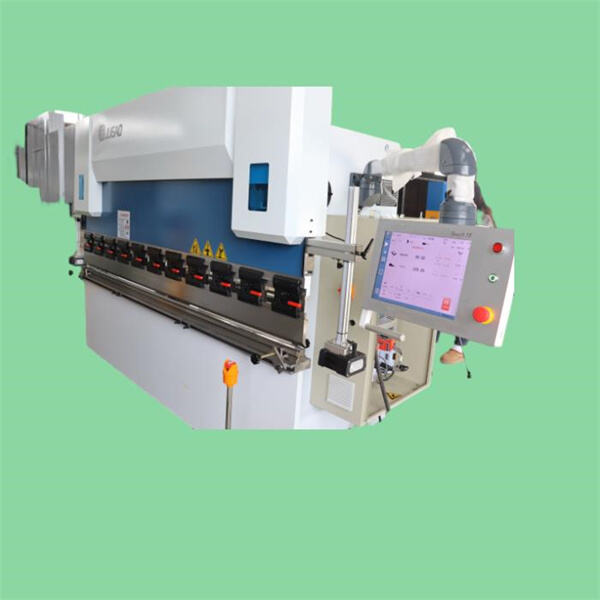

The Brake Press is a hard working machine which are commonly used in forming metal. It can bend metal sheets well and efficiently. At JUGAO, we offer our superb quality cnc tandem press brake to help fabricate a wide range of metal products.

A brake press a machine whose punch tool bends metal sheets. This is commonly known as pressing or forming. The brake press applies pressure to the metal sheet, causing it to bend at an angle. It is capable of making sharp bends as well as V-shaped bends, curves and such complex forming.

The tandem press brake machine itself has important pieces of equipment, such as the bed, ram, punch, and die. The bed is the surface on which the metal sheet lies as it is being bent. The ram is the force that moves and pushes along the metal sheet with the press. The punch is responsible for bending the metal, and the die supports the metal as it bends and can help control the angle of the bend.

A brake press is a great instrument to create various forms of metal products. From plain old brackets to intricate sculptures, the brake press is ready to do it all. With the right tools and setup, you can build a whole lot of things. At JUGAO, we have different models of brake press machine for your all needs.

The brake press has tremendous accuracy, and that’s a great thing. It's a lot more accurate than humans are." The machine can bend the metal down to an infinitesimal size, ensuring every single piece is the same and meets the dimensions required. It's that kind of versatility that makes the brake press ideal for producing lots of different goods, all of which are accurate in their quality.

To make your press brake work well, there are some tips to pay attention to. # 1 Have the correct tools A first thing to remember is always utilize the proper tools for the job. Various projects require various punches and dies, so use the correct ones for the bend angle and shape desired. Also, configure the machine properly before beginning a project. This process involves setting the back gauge, securing the metal sheet, and ensuring the tools are aligned.

Rolling Machines specialize metal sheet forming high-quality production. brake press offer flexible solutions pipe bent. product line centered around precision, efficiency stability order increase effectiveness quality products.

their precision efficacy laser cutting machines brake press range different materials. Rolling machines thanks excellent forming abilities efficient production meet needs many customers. Mass production requirements; Pipe Bending machines ideal variety pipe processing thanks flexible bending capabilities long-lasting performance. products embody essence latest industrial technology allow manufacturing industry tackle various challenges effectively, accurately flexibly.

Quality Builds Trust: Dedicated sheet metal machines carefully monitor quality make sure every machine highest standards industry. aim offer most efficient products clients. laser cutters press brakes, pipe bending, rolling, rolling machines.Swift Market Response: Leveraging effective brake press production management, promptly market demands. Delivery time can shortened week there ample inventory. enables quick equipment acquisitions gain competitive advantages.

recognize significance RD brake press. laser cutting machines, rolling machines pipe bending machines, products, provide entire range after-sales services includes Spanish after-sales service ensure customers enjoy hassle-free use. addition continue invest research development, help promote latest technology product development meet ever-changing needs customers, assist customers maintain position marketplace.