Brake metal sheet is a unique type of metal that is ideal for fabricating various metal products. It is very useful in a lot of work including, because it is strong and can be molded into different shapes. This metal is found in construction and automobiles as well. We learn how to work with brake metal sheet, tools you will use and how to select the correct for your projects.

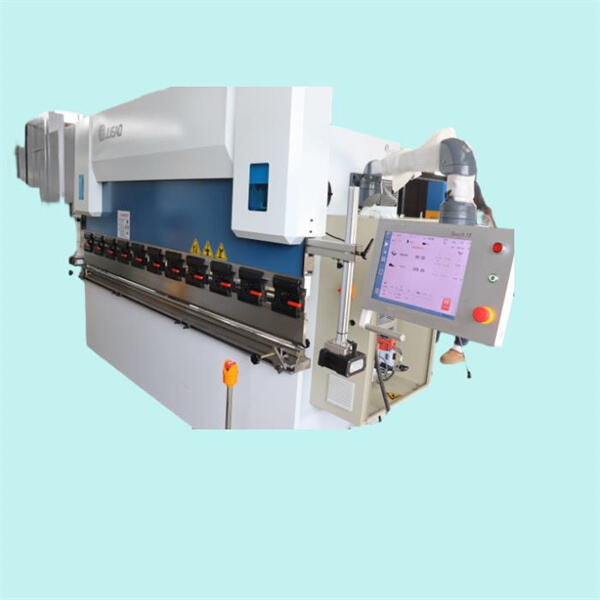

Brake metal sheet is an easily bent and shaped type of metal. To bend a flat piece of metal, people use a device called a brake press. This will help shape it into forms, which is great for a lot of projects. With brake metal sheet, you can form sharp angles, smooth curves, or straight lines.

There is a major reason that brake metal sheet is popular, and it is that it is incredibly strong. It’s not afraid of heavy things and tough weather. This means it’s great for construction, where strength is crucial. Additionally, brake metal sheet can be created in various sizes and styles. It’s the consistency and richness you want.

Brake metal sheet goes in many places, like construction and cars. It can also be used to make parts in construction, such as walls, beams and supports. It is strong, flexible, so it is fabulous for these types of jobs. In automobiles, brake metal sheet is used for body panels, frames and more. It is formable and is a Taurus[disambiguation needed] car choice for car making.

In order to bend brake metal sheet, you need to have some special knowledge and the proper equipment. The metal is most often bent on a brake press. Other tools, such as scissors and rollers, can also help cut and shape the metal. The reality is that it takes a bit of performing to be able to use these tools if you want to work with brake metal sheet optimally.

While choosing a brake metal sheet, you should consider what kind and how thick the metal will be necessary. The type of metal can influence its strength and longevity. They are available in stainless steel, aluminum, and steel. The thickness also matters. Thicker sheets are stronger and more difficult to bend; thinner sheets are easier to work with, but they may not be as strong.