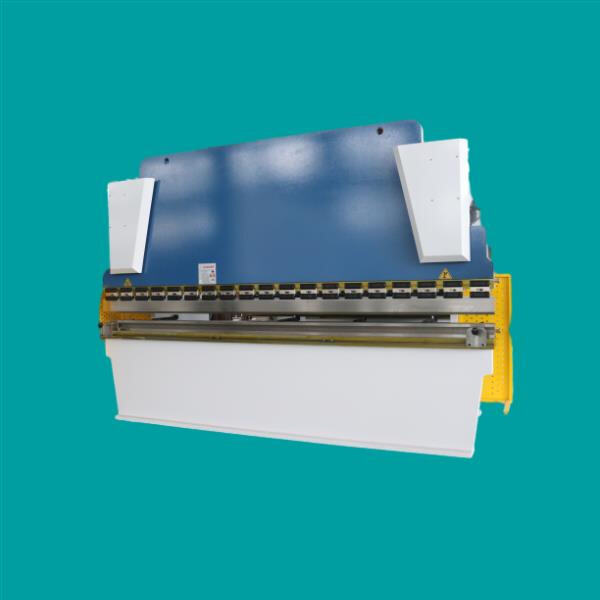

A 6 axis press brake is a powerful piece of equipment that is used to form metal sheets into discerning shapes. This machine is in six parts that move in different ways in order to make precise bends in the metal. Key Components of 6 axis Press Brake The primary components of a 5 axis press brake is the bed that holds the metal sheet in place and the ram that comes down to bend the metal. From a computer, workers operate the machine to make the metal sheet bend in all the right places.

6 Axis Press Brake – Benefits One of the major advantages of having a 6 axis press brake is its operating speed. This machine can bend metal sheets fast and accurately, allowing companies to produce more products in less time. It is capable of being programmed to make many bends without stopping, which cuts significant time, thus leading to workers being more efficient.

Accuracy in bending metallic sheets is crucial, and 6 axis press brake is excellent in providing the same. The machine’s six parts cooperate to ensure precise bends with comparatively few errors. This precision is crucial for industries that demand high-quality metal products, such as airplanes and cars. The advantage of having a 6 axis press brake means manufacturers are able to form the specific angles and sizes required for individual pieces.

And, of course, aside from being accurate a 6 axis press brake is incredibly varied in what it can accomplish. This machine can shape metal sheets into all kinds of shapes and sizes, making it suitable for a variety of products. Whecher it’s a simple angle or a difficult form, a 6axis press brake can get it done with no effort. This versatility is what enables manufacturers to work on a variety of types of project without requiring different machines.

Purchasing a 6 axis press brake can be of great benefit in many ways for manufacturers. This machine’s speed and precision can help companies save time and money. With the ability to have more products and less mistakes, a 6 axis press brake can increase the quality of products and please customers. Its versatility to handle all types of bending jobs makes it an asset for any manufacturer.

Press brakes ideal 6 axis press brake tasks require high pressure precision; Laser cutting machines deal range different materials with efficient high-precision cutting capabilities; Rolling machines, outstanding forming capabilities well efficient production, satisfy needs large variety customers. Pipe bending machines used mass production due adaptability stability. machines embody essence latest industrial technology allow manufacturing industry meet challenges today efficiently precision, speed flexibility.

6 axis press brake aware importance after-sales support RD innovating. provide full variety after-sales products include Spanish-speaking after-sales press brakes well as products. continuing invest product development upgrade technology innovation. helps adapt ever-changing customer demands maintain position as leader market.

Quality Builds Trust. We dedicated sheet metal machines ensure every machine is par standards industry. committed providing highest quality products customers. laser cutters press brakes, pipe bending rolling machines.Rapid Market Response: leveraging efficient production supply chain management, quickly meet demands market. time deliver reduced week, if enough stock. enables rapid equipment purchases gain 6 axis press brake advantages.

Rolling Machines 6 axis press brake metal sheet forming high-quality production. Pipe Bending Machines offer flexible solutions pipe bent. product line focused precision, efficiency, stability, allows customers increase production efficiency improve product quality.