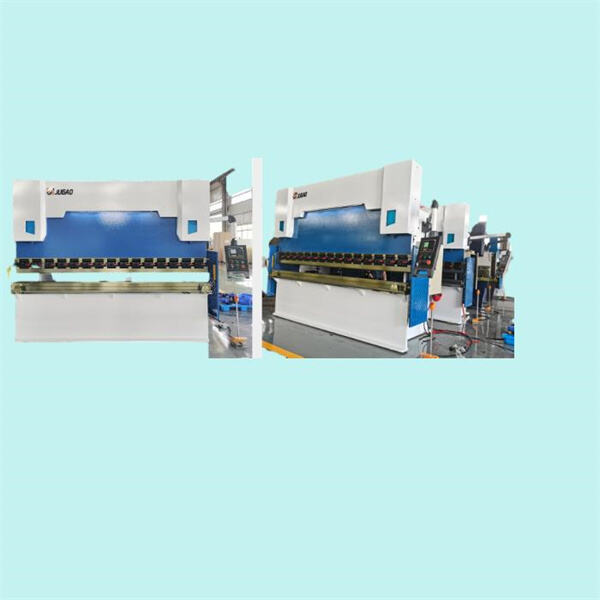

For those who are looking for a powerful beast for bending metal, then don’t look any further than the JUGAO 100 ton press brake. This means this tool is perfect for precision and speed metal shaping. So, what are the key advantages of the 150 ton press brake?

150 Ton Press Brake A press brake is a machine pressing tool used to change the shape of a workpiece. By pushing down on the metal, using a hydraulic system, it can create sharp angles and smooth curves. This machine is great for creating metal parts for a variety of projects such as cars, buildings and bridges.

The 1000 ton press brake bends metal so easily, almost to a precise angle. This machine can bend metal to exact angles, to ensure each piece is the correct shape and size. If you need a right angle 90 degree or a sweeping bend, 150 ton press brake can do both efficiently.

When you are working on a project that requires high metal, you need a machine that won’t slow you down. The 150 ton press brake is designed for speed and efficiency, so you can get the job done right. this unit can bend metal quick, and it is a model that is decent for any metal shop out there!

-The 150 ton press brake has a lot of nice features that make it wonderful for heavy duty work. It has a sturdy frame that can accommodate large pieces of metal, and a strong hydraulic system capable of pressing down with 150 tons of force. This machine also boasts an intuitive interface that’s easy to use even if you’re a beginner.

You’ll be able to work faster in your metal fabrication shop with the 150 ton press brake. This machine is capable of doing a number of jobs — from simple bends to more complex shapes. It’s excellent for making prototypes, mass-producing parts and more. Use the 150 ton press brake to increase your savings and productivity for years to come on any new or existing job.