What is the reason for dust generation when the metal laser cutting machine is working?

Many friends may have the impression that the metal laser cutting machine is a red light passing through, and the material is cut open, so where does the smoke and dust come from? Since the materials, sizes and thicknesses of the products processed by the laser cutting machine are different, the types of laser cutting equipment used are naturally different. So how is the dust generated during the cutting process?

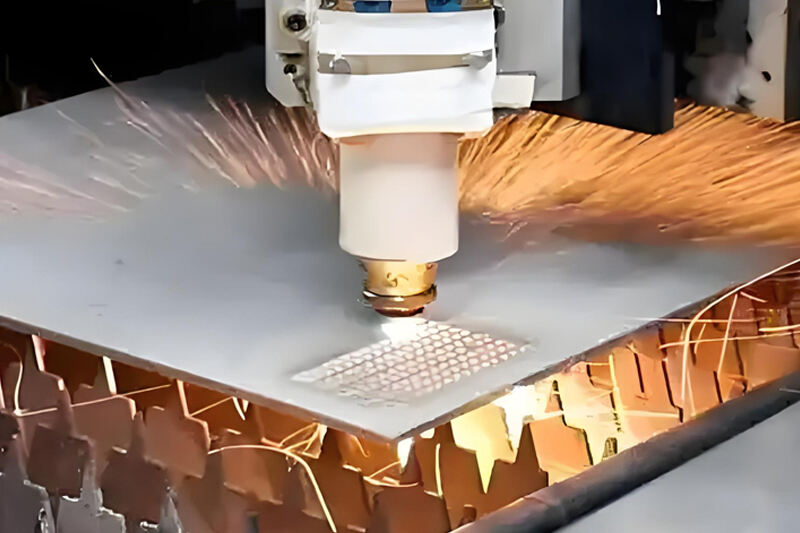

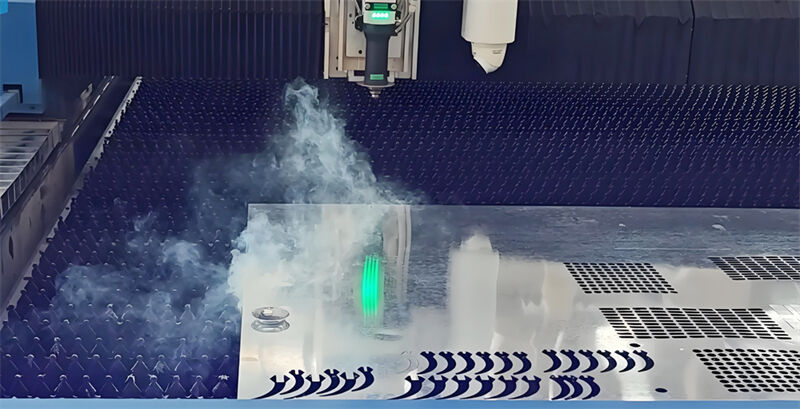

The working principle of the metal laser cutting machine is believed to be very clear to everyone. It uses a high-power density laser beam to irradiate the workpiece, so that the irradiated material is quickly melted and vaporized. At the same time, the high-speed airflow coaxial with the beam blows away the molten material, thereby realizing the cutting of the workpiece. This is also the process of dust and smoke generation.

Reasons for cutting dust

1. Laser oxidation cutting: The surface of the metal material can be quickly heated to the ignition temperature under the irradiation of the laser beam, and then it reacts with oxygen to release a large amount of heat, so that small holes are formed inside the material. The small holes are surrounded by molten metal walls. These steam and molten materials are carried away by the auxiliary airflow, and then float in the factory workshop, forming dust and smoke.

2. Laser vaporization cutting: Under the heating of high-power density laser, about 50% of the material vaporizes into steam and disappears, and the remaining material is blown away from the bottom of the cut by the auxiliary gas as ejecta, and combines with fine particles in the air to form dust.

3. Laser melting cutting: When the incident laser beam power density exceeds a certain value, the material at the irradiation point begins to evaporate, forming holes, and the material around the laser speed is melted. Then, the auxiliary airflow coaxial with the light speed takes away the surrounding molten material to form smoke.

The hazards of cutting smoke

The hazards of smoke are easily overlooked by the operator. The high temperature generated by the laser acts on the processed material, generating a large amount of steam and smoke. These smokes contain a large amount of chemical components, which are also harmful to the human body. In addition, some gases (such as carbon dioxide) generated by laser cutting are more likely to damage the human respiratory system.

Solution

1. It is recommended to install a set of dust collection equipment above the metal laser cutting equipment, which can effectively absorb dust and make the workshop cleaner and tidier.

2. You can choose to buy a large-surround metal laser cutting equipment, which is more beautiful in appearance, can be dust-proof, and can avoid the harm caused by metal chips splashing during processing.

The above are the reasons, hazards and solutions for the dust generated by the metal laser cutting machine during operation. Friends who need to know about large-surround laser cutting equipment are welcome to visit the JUGAO CNC MACHINE factory for an on-site inspection!