How Modern Laser Welding Works

Laser welding has made modern society flourish. Laser welding machines are relevant to modern advanced manufacturing and can be automated to increase your return on investment and overall productivity.

Here is a brief guide to modern laser welding and how these machines can revolutionize the way you work.

How Laser Welding Works

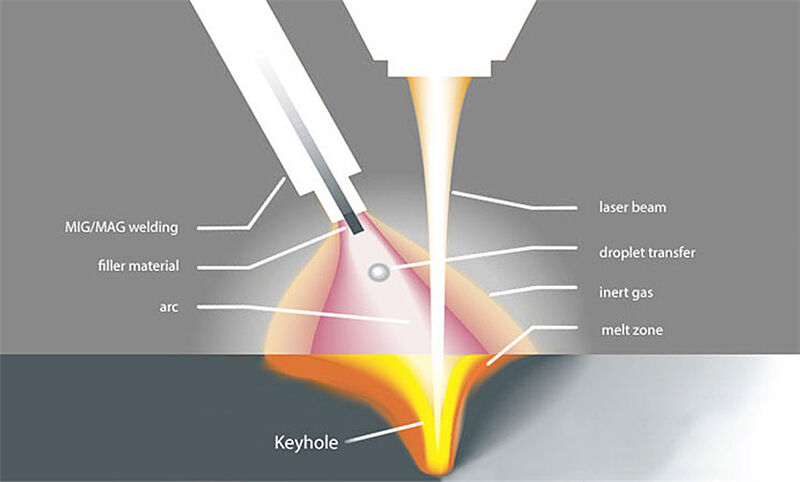

Laser beam welding works by harnessing the power of a high-powered fiber laser that is either continuous or even quasi-continuous. Welding with a laser requires a near infrared wavelength.

You can easily control the laser, and it can vary the resolution and speed at which it is performed.

Laser beam welding is suitable for many different types of projects, including those with different metals, shapes, and sizes. This makes laser welding machines a very useful tool in modern construction.

How is it different from arc welding?

Welding with a laser is different from traditional arc welding.

Fiber lasers are an overall safer system and in many cases easier to use. Arc welding does have limitations that are not an issue when using lasers.

Lasers affect a smaller area with their heat, which means there is less chance of cracks or damage to surrounding materials such as high carbon steel than with an arc welder.

Another difference is the option to use penetration welding or conduction welding. This creates more versatility for the welder.

Modern Changes That Will Revolutionize Your Business

Laser welding is an application that has been used in industrial welding for over half a century. Over the years, there have been technological advances that have made laser welding machines highly functional, multi-tasking machines.

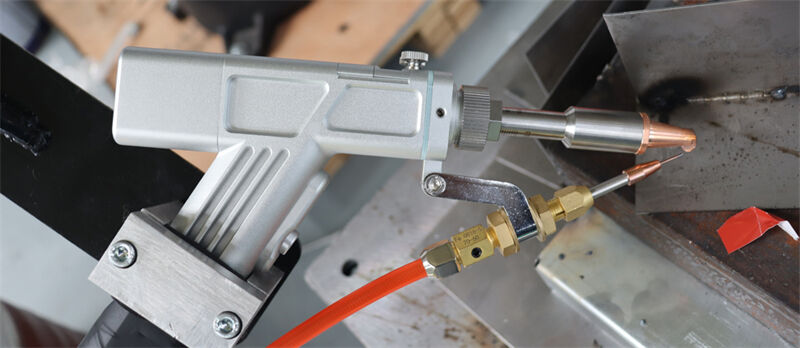

These powerful machines are now able to do everything in one. You can get a machine that can drill, cut, mark, and weld. If it isn’t one machine, you can find one with multiple interchangeable parts for your convenience.

Another thing that has changed is the amount of control that comes with new laser machine welding. They can be more precise than older models because the processing range is wider.

This increase in control will allow you to use lasers on different materials that require precision.

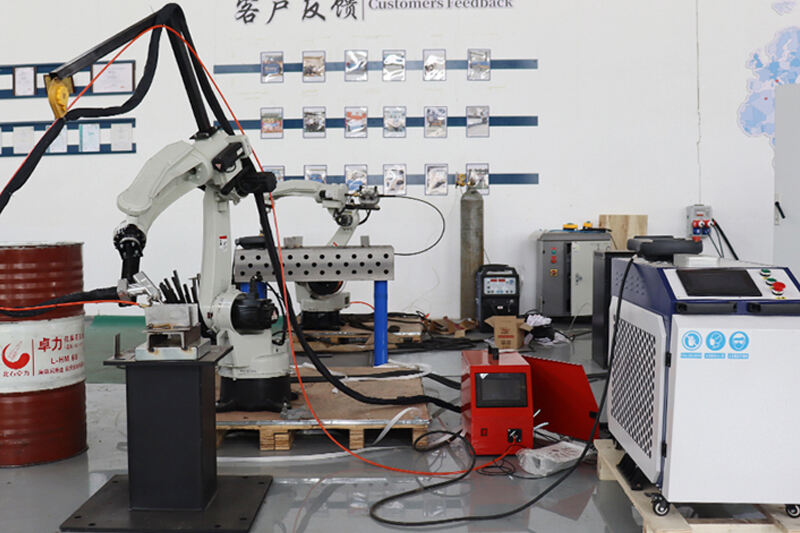

Increase Productivity and Return on Investment Through Automation

Automated modern laser welding machines reduce the need to hire experts to work on the factory floor. The machine is easily operated by any available worker because of the pre-determined settings.

Another advantage is that the welding process is simplified through the use of fiber lasers. This will allow you to produce a larger volume of overall products.

If you need to increase productivity, you can purchase more laser welding machines. This is an easy way to easily expand your business.

Innovative Tools

Automated laser welding systems aid in the manufacturing of new products and designs.

They can change the way you run your business by increasing production and putting money back in your wallet.Welcome to consult online to learn more about the machine information.