What are the criteria for judging the cutting quality of laser cutting machines?

With the development of science and technology, laser technology has been applied to all walks of life. Laser cutting, as a precision processing method, can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates. Laser cutting machines are a technological revolution in sheet metal processing and are the "processing center" in sheet metal processing.

Lasers use material excitation to generate light. This light has a strong temperature. When it contacts the material, it can quickly melt on the surface of the material to form a hole. The cutting is formed according to the movement of the alignment point. Therefore, compared with traditional cutting methods, this kind of cutting method has a smaller gap and a faster cutting speed.

The cutting quality and effect of the laser cutting machine are very good, but there are also many factors that affect the cutting quality of the laser cutting machine. So, what are the factors that affect the cutting quality of the laser cutting machine?

Analysis of factors affecting the cutting quality of the laser cutting machine:

1. Cutting width and verticality that affect the cutting quality of the laser cutting machine

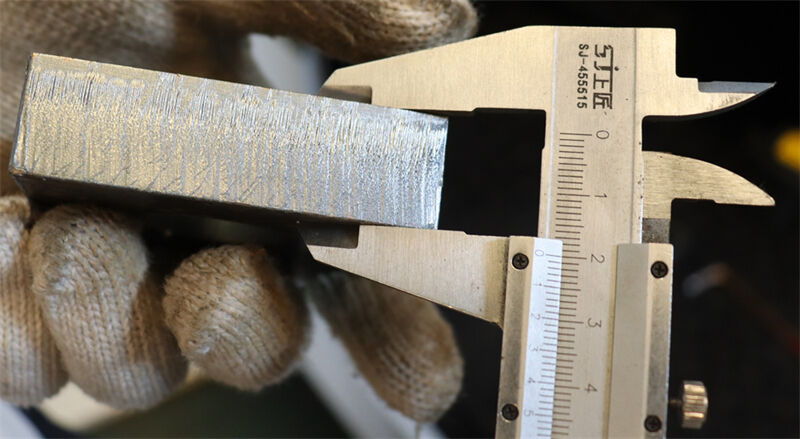

The width of the cut usually does not affect the quality of the cut. The cutting width is important only when a particularly precise contour is formed inside the part. This is because the width of the cut determines the contour. As the thickness of the sheet increases, the width of the cut also increases. If the thickness of the metal sheet exceeds 10mm, the verticality of the cutting edge is very important. When away from the focus, the laser beam becomes divergent. Depending on the position of the focus, the cut becomes wider towards the top or bottom. The more vertical the edge, the higher the cutting quality.

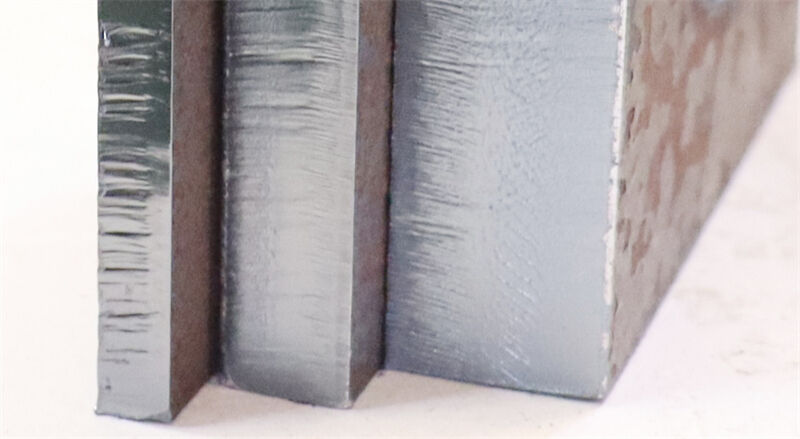

2. Roughness and texture that affect the cutting quality of the laser cutting machine

The laser cut part will form a vertical texture. The depth of the particles determines the roughness of the cut surface; the shallower the particles, the smoother the cut part. In most cases, the roughness must be reduced as much as possible, so the lighter the texture, the higher the cutting quality. When cutting slabs at high speed, the molten metal does not appear in the slit under the vertical laser beam, but is ejected after the laser beam is deflected. As a result, a curve is formed at the cutting edge, and the line closely follows the moving laser beam. To solve this problem, the feed speed is reduced at the end of the cutting process.

3. Material deposition, burrs, and deformation that affect the cutting quality of laser cutting machines

During the cutting process, the surface of the slit can form surface deposition, and the amount of deposited material can also see the quality of the laser cutting equipment. The formation of burrs determines a very important factor in the quality of laser cutting, because removing burrs requires additional workload, so the severity and quantity of burrs can directly determine the quality of cutting. If the cutting causes the part to heat up sharply, deformation will occur, so the smaller the deformation, the better the cutting quality.

The above is an analysis of the factors that affect the cutting quality of laser cutting machines. The main products of JUGAO CNC MACHINE include laser cutting machines, fully CNC hydraulic bending machines, laser welding machines, plate rolling machines, pipe bending machines and laser application automation equipment, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries. Welcome to consult online.