What is the positive and negative focal length of a metal laser cutting machine?

Metal laser cutting machines use high-power density laser beams to scan the surface of materials, heat the materials to thousands to tens of thousands of degrees Celsius in a very short time, melt or vaporize the materials, and then use high-pressure gas to blow away the melted or vaporized materials from the cut to achieve the purpose of cutting materials.

Metal laser cutting machines are used in various manufacturing and processing industries such as sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and metal external processing. Metal laser cutting machines are mainly used for rapid cutting of various metal materials such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling sheet, aluminum zinc sheet, copper, etc.

So, what is the positive and negative focal length of a metal laser cutting machine? What is the relationship between the focal length of a laser cutting machine and the material?

Analysis of the relationship between the positive and negative focal lengths of metal laser cutting machines and materials:

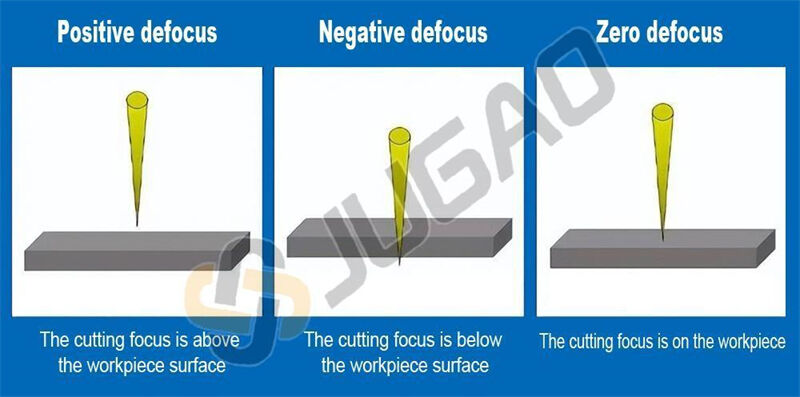

1. The cutting focus of the laser cutting machine is on the surface of the workpiece

This method is the most common focal position, also known as 0 focal length, and is often used to cut workpieces such as SPC/SPH/SS41. When used, the focus of the cutting machine is selected close to the surface of the workpiece. In this mode, the upper and lower surfaces of the workpiece have different smoothness. Generally speaking, the cutting surface close to the focus is relatively smooth, while the lower surface far from the cutting focus appears rough. This mode should be determined according to the process requirements of the upper and lower surfaces in actual applications.

2. The cutting focus of the laser cutting machine is on the workpiece

This method is called negative focal length, because the cutting point is not located on the surface of the cutting material or inside the cutting material, but is located above the cutting material. Generally, this focus is used because the thickness of the plate is relatively high. If the focus is not positioned in this way, it may cause insufficient oxygen to be delivered by the nozzle, resulting in a drop in cutting temperature and failure to cut the material. However, a significant disadvantage of this method is that the cutting surface is rough and not suitable for precision cutting.

3. The cutting focus of the laser cutting machine is inside the workpiece

This method is called positive focal length, and it is generally used when cutting materials such as stainless steel or aluminum steel plates, so that the cutting focus is located inside the workpiece. The main disadvantage of this method is that the cutting amplitude is larger than the cutting point on the surface of the workpiece, and this mode often requires a stronger cutting airflow, sufficient temperature, and longer cutting and perforation time. Therefore, it is only used when cutting hard materials such as stainless steel or aluminum.

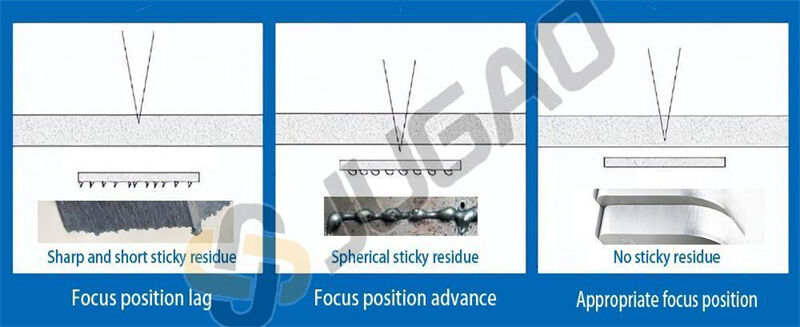

The impact of focus on cutting:

1. The focus position is lagging, sharp and short slag;

2. The focus position is advanced, spherical slag;

3. The focus position is appropriate, no slag.

Users can choose the appropriate focus cutting method according to the different effects of different focuses when cutting materials and their own processing needs, so as to better exert the performance advantages of the laser cutting machine!

The above is the relationship between the positive and negative focal lengths of metal laser cutting machines and materials. JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.