Ever see metal sheet bent in a new form? This is a pretty fascinating process! This bending is performed by a specific machine called press brake. Press Brake Clamp is one of the important parts in press brake. In this article, we are going to take a closer look at those clamps and find out why they play such an important role in the process of bending metal so that it can be carried out effectively and safely.

While using a press brake to bend metal, it is an imperative aspect ensure the Metal stays still and in accurate position. Press Brake from CollectionThat is where press brake clamps come in. They work like powerful, hold down hands that clamp the metal to prevent it from twisting and shifting while being bent.

A clamp is not a clamp. Thinking all clamps are the same, wagging in line like flightless metal sprites toward mate bolt play, would be your first mistake as an amateur wood slapper around here! Some clamps better fitting than the others and can hold a metal more precise. Now this is essential for thin or delicate sheets where you must bend a nice radius. If the clamps do not grip well to hold the sheet metal, then it may be deformed during bending.

This clamps can be modified and adapt for a lots of different metals and thicknesses. So, you are allowed to be very creative with your bending creations and records on this. You can cure the cast using sunlight or you could bake at it 85 degree Celsius to harden upThen design as follows.

You will no longer have to shut down work in order to repair the clamp that has failed you. If coming from a reliable set of clamps is all again just keeping it simple way home! This translates into saving a lot of money and time in the long run allowing you to focus on completing your project effectively.

If you are not cautious, it can be hazardous to operate a press brake. This is why it becomes so crucial to employ clamps which are durable and sturdy as much that they can hold the stress and force exerted on other metal objects when you need bend some blanks in a certain way. Whatever your project, safety first when working with metal.

Each clamp is adjustable so you can set the angle, height and width of the clamp to guarantee that your repeatable bend will be spot-on every single time. Especially when working with metals it is useful to have for your projects because of how more precise this tool can be. Customization of Your ClampsAll This is possible because you are able to customize your clamps and get precisely the results that you desire

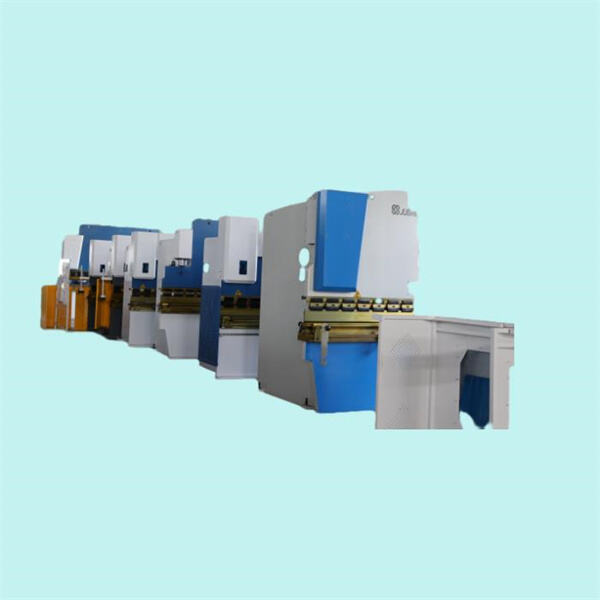

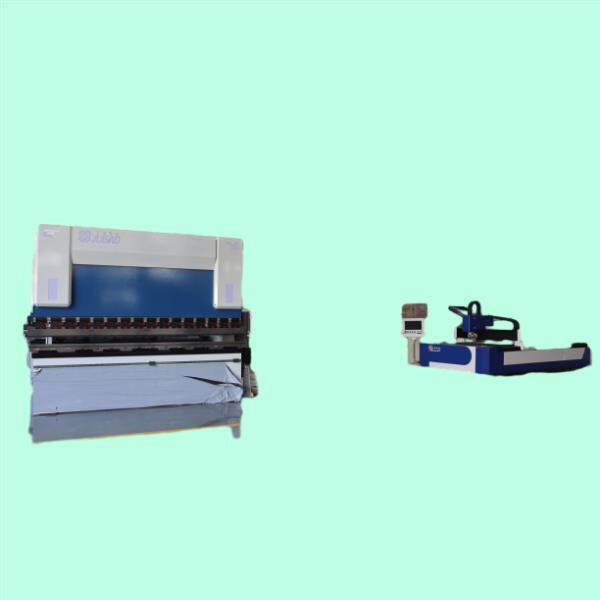

Quality Builds Trust. believe sheet metal equipment make sure every machine line industry standards. press brakes, laser cutters pipe benders rolling machines strive provide top-quality products ease anxiety customers.We respond rapidly market Press brake clamps using effective supply chain production management. ample inventory, delivery time shortened one week, allows rapid acquisition equipment gaining advantage market.

Press brake clamps Brakes known reliability precision used many metal sheet processing. Laser Cutting Machines high-speed, high-precision cuts satisfy most complex requirements pattern design; Rolling Machines specialized metal sheet forming ensure top quality production. Pipe Bending Machines offers flexible pipe Bending solutions. product range focused precision, efficiency stability order improve production effectiveness quality products.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Press brake clamps.

Press brake clamps accuracy effectiveness Laser cutting machines handle wide range materials. Rolling machines excellent forming abilities efficient production meet demands many customers. Pipe bending machines utilized mass production due flexibility stability. essentials industrial technology aid manufacturing industry adapt various challenges efficiently, accurately flexibility.