Press Brake Precision and Performance Evaluation Guide

Press Brake Precision and Performance Evaluation Guide

In metal fabrication, press brakes serve as critical equipment for achieving precise bends in sheet metal. The accuracy and efficiency of these machines directly influence product quality and production throughput. This comprehensive guide outlines systematic approaches to assess both the precision and operational performance of press brake equipment, ensuring optimal functionality throughout its service life.

Evaluating Press Brake Precision

Precision evaluation focuses on three fundamental aspects that determine bending accuracy:

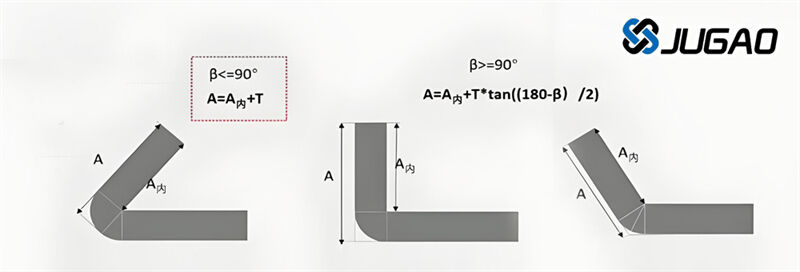

1. Bend Angle Measurement

Utilize digital angle finders or precision protractors to measure formed angles against specified tolerances. For optimal results:

Conduct measurements immediately after bending while material memory effects are present

Compare multiple samples from different positions across the working length

Document variations exceeding ±0.5° as potential calibration issues

2. Parallelism Verification

Tool alignment critically affects bend uniformity. Verification protocol:

Mount dial indicators on the ram at 200mm intervals

Perform full stroke movements while recording deviation

Acceptable tolerance: ≤0.02mm per 100mm of working length

Correct misalignment through toolholder adjustments or machine recalibration

3. Process Consistency Analysis

Consistency Testing

Execute sequential bending tests with identical parameters to evaluate:

Angle reproducibility across 20+ consecutive cycles

Material springback consistency

Tooling wear patterns affecting dimensional stability

Statistical process control methods help identify developing trends requiring intervention.

Assessing Operational Performance

Beyond precision, operational metrics determine production efficiency:

1. Cycle Time Optimization

Time complete bending cycles from ram descent to return

Compare actual times against manufacturer specifications

Analyze acceleration/deceleration profiles for improvement opportunities

Target ≥90% of rated cycle speed in production conditions

3. Control System Functionality

Control Interface

Modern CNC systems should demonstrate:

Intuitive programming interface responsiveness

Accurate axis position feedback

Predictive error prevention capabilities

<100ms command execution latency

Conduct test programs combining multiple bend sequences to verify stability.

4. Hydraulic System Evaluation

Monitor pressure transducers during operation to identify:

Pump efficiency degradation

Valve response times

Pressure fluctuations exceeding ±5% of setpoint

Abnormal thermal signatures indicating component wear

Maintain detailed pressure logs for predictive maintenance scheduling.

Frequently Asked Questions

Q: What's the most accurate method for bend angle verification?

A: Laser-based measurement systems provide ±0.1° accuracy, though digital protractors (±0.5°) suffice for most applications when properly calibrated.

Q: How to address inconsistent bend angles across the working length?

A: First verify tool parallelism, then check for ram deflection using strain gauges. Thermal compensation may be required for machines with >3m working lengths.

Q: Recommended evaluation frequency for production equipment?

A: Perform basic checks weekly, comprehensive evaluation quarterly, or after 50,000 cycles. Increase frequency when working with high-tensile materials.

Conclusion

Systematic evaluation of press brake equipment incorporates both precision verification and performance benchmarking. Implementing regular assessment protocols minimizes quality deviations while maximizing equipment utilization. For specialized applications requiring tighter tolerances, consider integrating automated measurement systems with real-time process adjustment capabilities.

JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.