How to choose the right high-tonnage bending machine?

In the field of metal processing, choosing the right bending machine is crucial to ensure the precise bending and forming of metal sheets. If you are considering purchasing a high-tonnage bending machine, then you may need a powerful machine that can handle heavy-duty processing tasks. This article will give you a detailed introduction to the key factors to consider when purchasing a high-tonnage bending machine, helping you make a wise choice based on your actual needs.

The core elements of purchasing a high-tonnage bending machine

1. Evaluation of material thickness and type

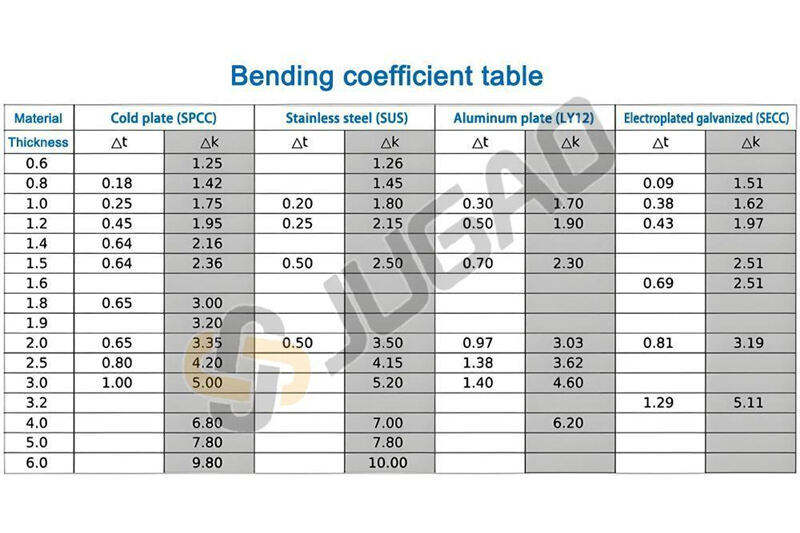

The first step in choosing a high-tonnage press brake is to determine the type of metal material you need to process and its thickness. High-tonnage press brakes are designed for thick plate processing, so it is important to understand the thickness range of the material. For example, when processing stainless steel or aluminum alloy, you need to ensure that the press brake can provide enough pressure to complete efficient bending. At the same time, the hardness of different materials will also affect the choice of machine. It is recommended to consult professional technicians according to specific needs.

2. Bending length and stroke requirements

The bending length refers to the maximum length of metal sheet that can be processed in a single operation, while the stroke determines the bending depth that the machine can achieve. When purchasing, you need to evaluate these two parameters according to your production needs. For example, when processing extra-long plates, you need to choose a model with sufficient bending length; while complex-shaped workpieces may require a larger travel space.

3. Machine accuracy and stability

High precision is one of the core advantages of high-tonnage bending machines. To ensure processing quality, it is recommended to choose equipment equipped with advanced control systems, programmable backgauges and high-precision molds. These features can not only improve processing efficiency, but also reduce errors, especially suitable for large-scale production.

4. Control system and automation level

Modern high-tonnage bending machines are usually equipped with a variety of control systems, including manual, numerical control (NC) and computer numerical control (CNC). Among them, CNC systems have the highest degree of automation and are suitable for complex and high-precision processing tasks. If your production involves orders of multiple varieties and small batches, CNC bending machines will significantly improve production flexibility and efficiency.

5. Choice of hydraulic and mechanical bending machines

Hydraulic bending machines are more common in high-tonnage applications because they can provide stable pressure output and are suitable for processing thick plate materials. Mechanical bending machines are faster and have lower energy consumption, but they are more suitable for lightweight processing. Choosing the right type according to your production needs can effectively balance efficiency and cost.

6. After-sales service and maintenance support

Maintenance of high-tonnage bending machines is crucial. When purchasing, be sure to confirm whether the manufacturer provides comprehensive after-sales service, including warranty policy, spare parts supply and technical support. Regular maintenance (such as a comprehensive inspection every 500 hours) can extend the life of the equipment and reduce downtime.

Common types of high-tonnage bending machines

1. CNC bending machine

CNC bending machines are known for their high precision and automation level, and can easily complete complex bending tasks. Through programming control, operators can quickly switch between different processing programs, which is very suitable for multi-variety, high-precision production needs.

2. Hydraulic bending machines

Hydraulic bending machines have become the first choice for high-tonnage processing due to their stable power output. It is suitable for industries that require high pressure and high precision, such as aerospace and heavy machinery manufacturing.

3. Mechanical bending machine

Mechanical bending machines have simple structures and strong durability, and are suitable for lightweight processing with high speed requirements. Some models can also adapt to high tonnage requirements through special configurations, but they need to be evaluated according to specific application scenarios.

FAQ

How to calculate the required tonnage?

The selection of tonnage requires a comprehensive consideration of material type, thickness and bending length. It can usually be estimated by material width and thickness, but it is recommended to consult a professional to ensure accuracy.

What is the main difference between hydraulic and mechanical bending machines?

Hydraulic bending machines are suitable for thick plate processing and have stable power output; mechanical bending machines are fast and have low energy consumption, but are more suitable for thin plate processing.

What is the maintenance frequency of high-tonnage bending machines?

It is recommended to conduct a comprehensive inspection every 500 hours, and daily maintenance includes cleaning, lubrication and leak detection.

Summary

When choosing a high-tonnage bending machine, it is necessary to fully evaluate the material characteristics, processing requirements and equipment performance. By focusing on core elements such as tonnage, accuracy, and automation level, you will be able to find the equipment that best suits your production needs. If you need further assistance, please contact our professional team for customized solutions.JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.