How to Select the Optimal Backgauge Axis for Your Press Brake

Choosing the right backgauge axis for your press brake is a critical decision

that directly impacts the accuracy, efficiency, and versatility of your bending

operations. An improperly selected axis can lead to production delays, material

waste, and inconsistent results. This guide will walk you through the key

considerations and help you identify the best backgauge configuration for your

specific needs.

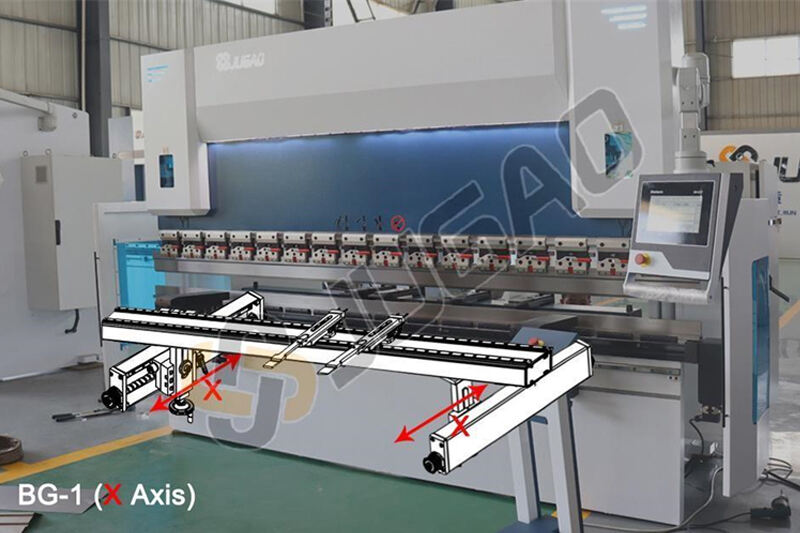

1. BG-1 (X Axis): Simplicity for Basic Bending

The X Axis is the most fundamental backgauge setup, offering linear horizontal movement of the backgauge fingers. This configuration is ideal for straightforward bending tasks where materials need consistent positioning along a single plane.

Advantages:

Cost-effective and easy to operate.

Perfect for repetitive bends on small or simple parts.

Minimal setup time for standardized production runs.

Limitations:

Lacks flexibility for complex or multi-angle bends.

Manual adjustments may be required for varying material thicknesses.

Best For:

Operators handling high-volume, low-complexity tasks where speed and simplicity are priorities.

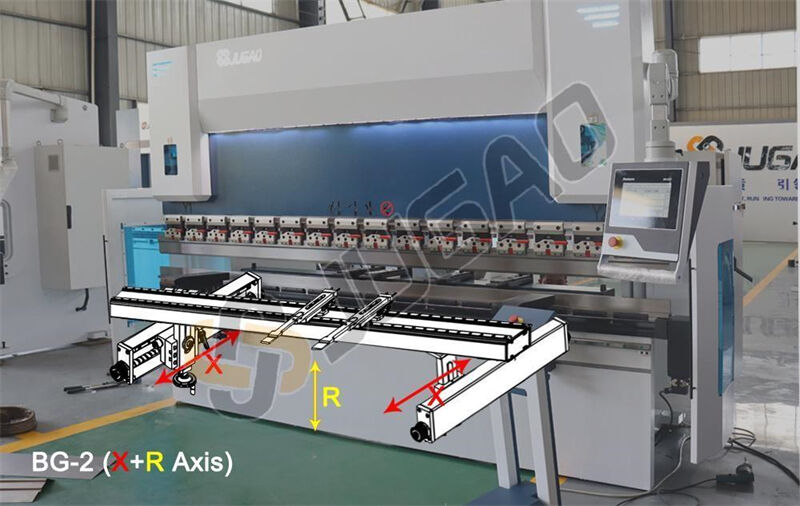

2. BG-2 (X+R Axis): Enhanced Flexibility for Angled Bends

The X+R Axis system combines horizontal movement with rotational adjustment, enabling precise positioning for angled or non-linear bends. The R Axis allows the backgauge fingers to rotate, accommodating more intricate part geometries.

Advantages:

Improved accuracy for V-shaped or asymmetrical bends.

Reduces manual intervention for angled adjustments.

Maintains efficiency while handling moderately complex tasks.

Best For:

Workshops producing parts with varying angles or requiring consistent repeatability across multiple bends.

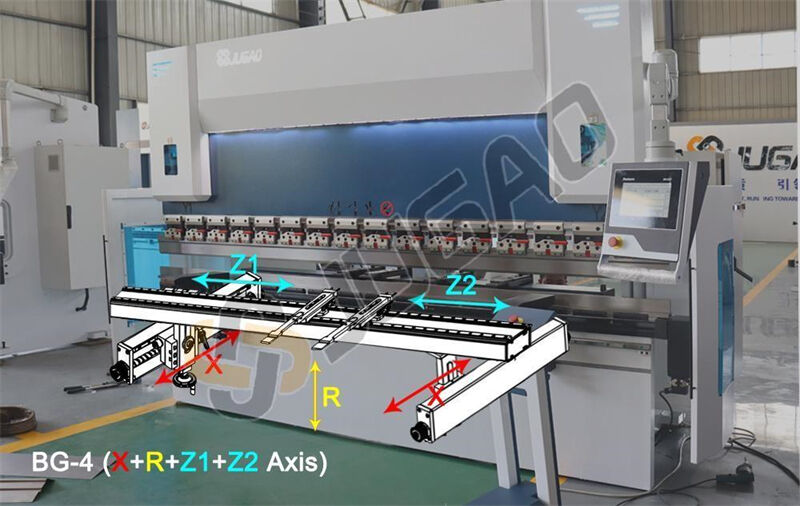

3. BG-4 (X+R+Z1+Z2 Axis): Precision for Multi-Dimensional Bending

The X+R+Z1+Z2 Axis configuration introduces vertical adjustments (Z1 and Z2) alongside horizontal and rotational movement. This setup is designed for high-precision applications where material thickness or bend depth varies.

Advantages:

Enables height adjustments for thick or multi-layered materials.

Ideal for parts requiring sequential bends at different depths.

Minimizes setup changes between operations.

Best For:

High-mix production environments where versatility and precision are essential.

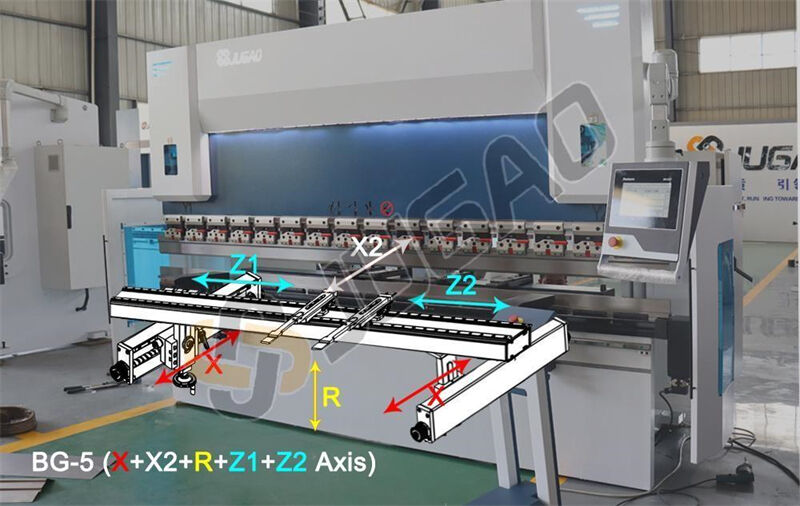

4. BG-5 (X+X2+R+Z1+Z2 Axis): Advanced Control for Complex Parts

The X+X2+R+Z1+Z2 Axis system adds a second horizontal axis (X2), allowing independent movement of backgauge fingers. This is particularly useful for large or irregularly shaped parts with non-uniform bending requirements.

Advantages:

Supports simultaneous positioning for multiple bend points.

Enhances efficiency for oversized or asymmetrical components.

Combines rotational and vertical adjustments for maximum adaptability.

Best For:

Manufacturers dealing with complex, multi-bend parts or custom fabrication.

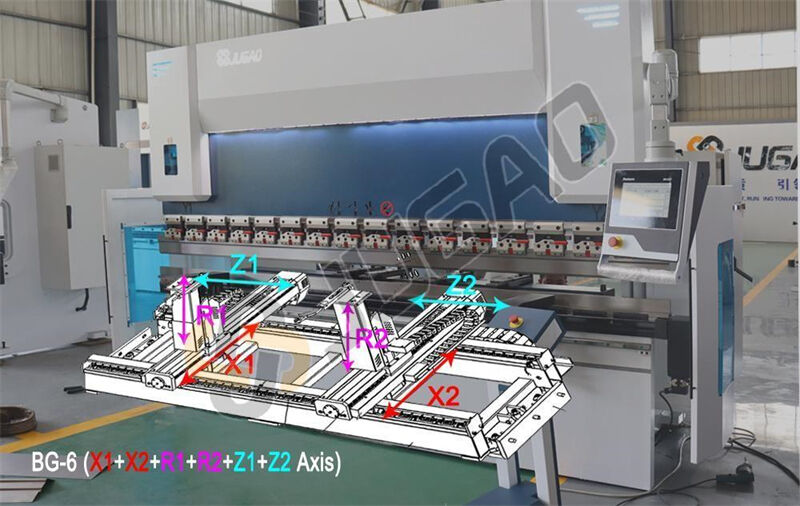

5. BG-6 (X1+X2+R1+R2+Z1+Z2 Axis): Ultimate Precision for Demanding Applications

The X1+X2+R1+R2+Z1+Z2 Axis represents the pinnacle of backgauge technology, offering independent control over two horizontal, two rotational, and two vertical axes. This configuration is engineered for the most challenging bending tasks.

Advantages:

Unmatched precision for aerospace, automotive, or heavy machinery components.

Handles intricate geometries with multiple bends and angles.

Reduces errors and rework in high-stakes production.

Best For:

Industries requiring zero-tolerance accuracy and the ability to process highly complex parts.

Key Selection Criteria

When choosing a backgauge axis, consider the following factors:

Material Type: Thicker or harder materials may require multi-axis adjustments.

Bend Complexity: Simple bends need fewer axes, while intricate designs demand advanced configurations.

Production Volume: High-volume runs benefit from automation-friendly setups.

Part Size: Larger or irregularly shaped parts often need dual-axis or rotational control.

Conclusion

Selecting the right backgauge axis is a balance between your operational needs and the capabilities of your press brake. By understanding the strengths of each configuration, you can optimize your workflow, reduce waste, and achieve consistent, high-quality results.

For tailored recommendations, consult with a press brake specialist or manufacturer JUGAO CNC MACHINE to ensure your equipment aligns with your production goals.JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.

Upgrade your bending process today—precision starts with the right backgauge!