Precision Adjustment of Press Brake Backgauge Stop Fingers: A Comprehensive Guide

Accurate backgauge alignment is critical for achieving consistent, high-quality bends in metal fabrication. Misaligned stop fingers can lead to dimensional inaccuracies, material waste, and production delays. This guide provides a systematic approach to diagnosing and correcting backgauge misalignment, ensuring optimal performance of your press brake.

Safety and Preparation

Step 1: Machine Preparation and Safety Protocols

1. Power Down: Completely shut off the press brake and disconnect it from all power sources to prevent accidental activation.

2. PPE Requirements: Equip yourself with:

ANSI-approved safety goggles to protect against flying debris

Cut-resistant gloves for handling sharp components

Steel-toe footwear for impact protection

3. Workspace Inspection: Clear the area of obstructions and verify that all safety guards are functional before proceeding.

Diagnostic Procedures

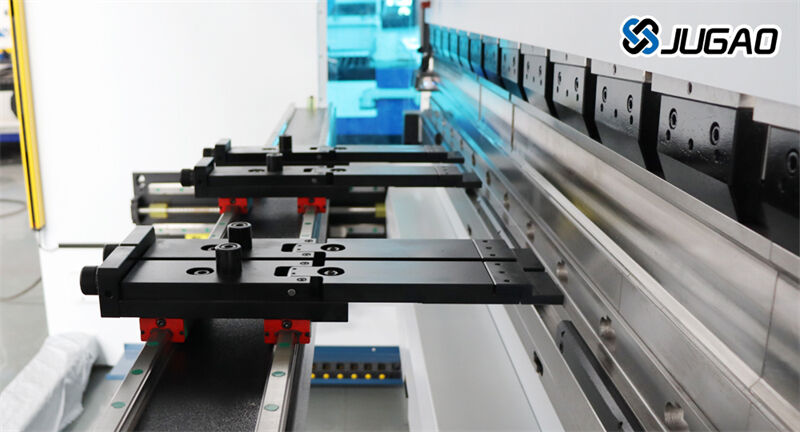

Step 2: Backgauge Access and Initial Assessment

Locate the backgauge assembly, typically positioned at the machine's rear

Remove any necessary access panels using appropriate tools (hex keys, wrenches)

Visually inspect:

# Linear guide rails for wear or debris

# Stop finger mounting integrity

# Drive system components (ballscrews, motors)

Step 3: Error Identification and Isolation

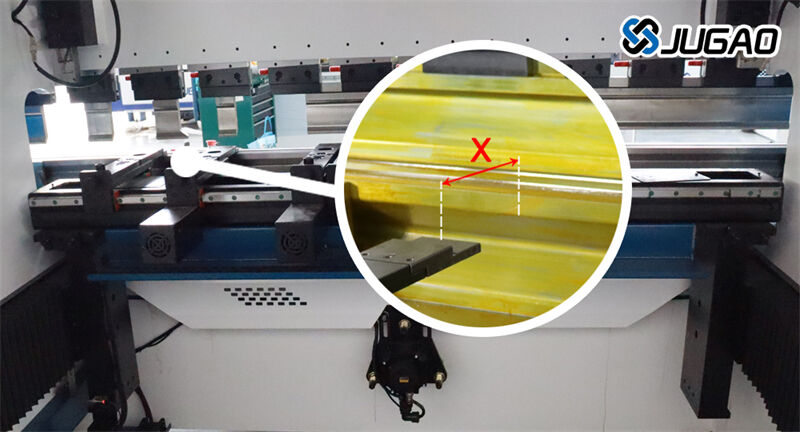

Beam Alignment Verification:

1. Measure from the right stop finger to the lower die edge using a digital caliper (accuracy ±0.02mm)

2. Reposition the gauge to the left extreme and repeat measurement

3. Diagnostic Interpretation:

# Consistent measurements indicate proper beam alignment

# Variance suggests beam parallelism issues (e.g., 2mm offset shown in video reference)

Stop Finger Calibration Check:

1. Measure multiple stop fingers at identical programmed positions

2. Troubleshooting Findings:

# Uniform measurements confirm proper calibration

# Discrepancies (e.g., 2mm variation between fingers) indicate individual stop adjustments required

Alignment Procedures

Step 4: Precision Adjustment Techniques

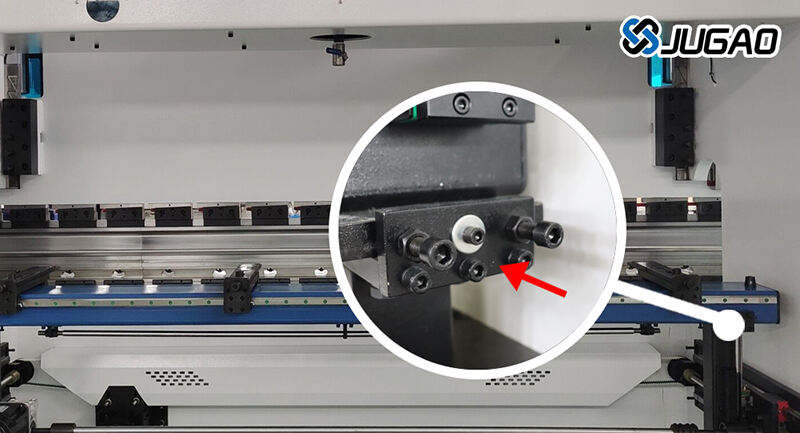

Beam Parallelism Correction:

1. Loosen all adjustment fasteners (typically M8 hex screws)

2. For increased beam distance:

Tighten flanking screws while loosening center screw

3. For decreased distance:

Tighten center screw while loosening side screws

4. Pro Tip: Make incremental 1/4-turn adjustments, verifying with dial indicators

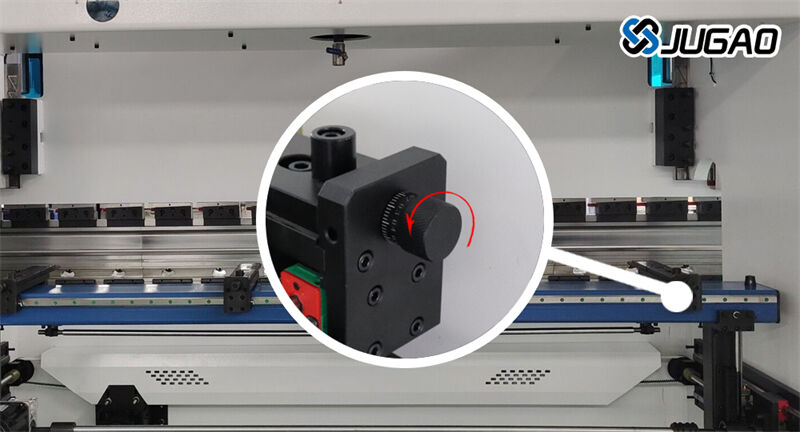

5. Stop Finger Micro-Adjustment:

1. Release set screws (usually two per finger)

2. Rotate adjustment rollers:

# Clockwise increases projection

# Counterclockwise decreases projection

3. Best Practice: Use feeler gauges to verify 0.05mm precision before final tightening

Verification and Quality Assurance

Step 5: Operational Testing

1. Re-energize the press brake and home all axes

2. Execute test bends using:

# Standardized test pieces (e.g., 2mm CRS)

# Certified angle measurement tools (digital protractors)

3. Acceptance Criteria:

# Angular tolerance within ±0.5°

# Linear dimensions within ±0.1mm of programmed values

Step 6: Final Commissioning

1. Complete system inspection checklist:

# Torque verification on all fasteners

# Lubrication of linear motion components

# Confirmation of safety interlock function

2. Document adjustment parameters in maintenance logs

3. Conduct operator briefing on any procedural changes

Maintenance Recommendations

Perform alignment checks every 250 operating hours

Establish preventive maintenance schedule:

# Monthly: Guideway cleaning and re-lubrication

# Quarterly: Ball screw backlash inspection

# Annually: Full geometric accuracy verification

Conclusion

Proper backgauge alignment directly impacts part quality, tooling life, and overall equipment effectiveness. By implementing this methodical adjustment process and maintaining rigorous calibration standards, manufacturers can achieve consistent bending accuracy while extending machine service life.