Methods for Accurately Adjusting the Bending Angle of CNC Press Brakes

Bending angle deviations can lead to inconsistent workpiece forming and quality problems. Mastering the precise adjustment methods of CNC press brakes is the key to ensuring that ideal results are achieved every time you bend. This article will detail how to achieve precise control of the bending angle through synchronization rod adjustment to help you improve processing accuracy and work efficiency.

Bending angle adjustment steps

1. Understand the role of the synchronization rod

The synchronization rod is the core component of the CNC press brake, responsible for ensuring that the cylinders on both sides move synchronously, thereby maintaining parallelism during the bending process. Any deviation will directly affect the accuracy of the bending angle.

2. Safety preparation

Turn off the power of the press brake and ensure that the equipment stops running completely.

Wear protective gloves and goggles to ensure safe operation.

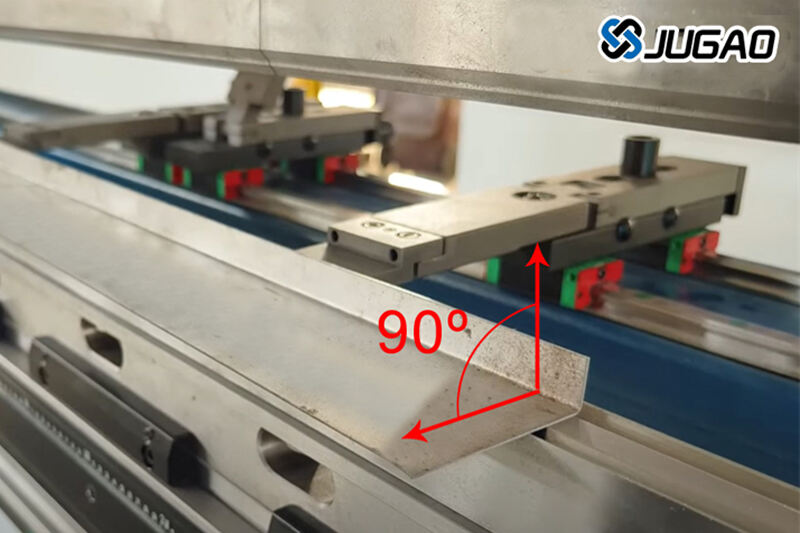

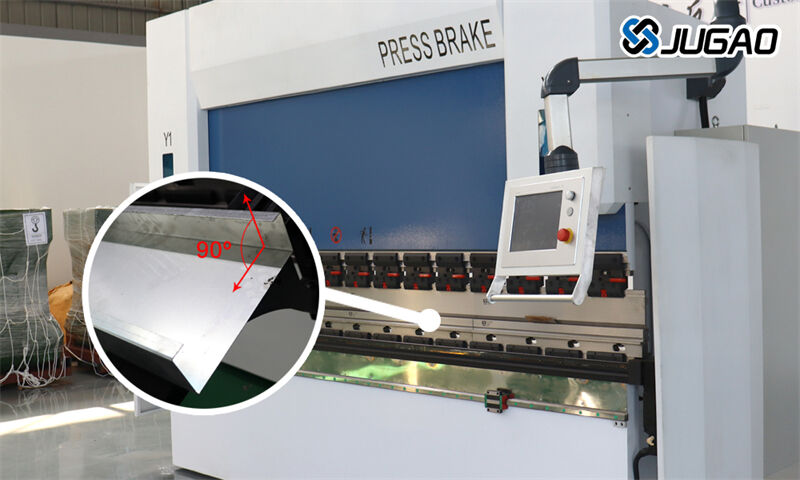

3. Measure the initial angle

Place a test plate under each cylinder on both sides.

Perform two bends using the same procedure and measure the bending angles on both sides respectively.

Record the difference between the angles on both sides as a basis for adjustment.

Schematic diagram of bending angle measurement

4. Adjust the synchronization rod

Position the synchronization rod: Find the adjustment position of the synchronization rod according to the equipment design.

Move the connecting sleeve: move the hexagonal connecting sleeve to the specified positionRotation adjustment:

Rotating the synchronization rod counterclockwise can increase the bending depth, thereby reducing the bending angle.

Usually, the bending angle changes by about 1 degree for each rotation (taking V16 slot and 1.8mm plate as an example).

Move the locking sleeve: After adjustment, move the locking sleeve to ensure that the synchronization rod is stable.

5. Test and verification

Use scrap material for test bending to measure whether the actual angle meets the requirements.

If there is still deviation, repeat the adjustment steps until the target angle is reached.

6. Final inspection and maintenance

Confirm that all adjustment parts are tightened to avoid loosening during operation.

Check the status of the synchronization rod regularly to ensure that the accurate angle is maintained for a long time.

Precautions

Be patient and meticulous when adjusting to avoid excessive rotation that causes excessive angle deviation.

Different plate thickness and slot type will affect the adjustment effect, and flexible operation is required according to actual conditions.

It is recommended to record the parameters after each adjustment to facilitate subsequent maintenance and optimization.

Through the above steps, you can effectively solve the problem of inconsistent bending angles and improve product quality and production efficiency.

JUGAO CNC MACHINE's main products include laser cutting machines, CNC hydraulic bending machines, laser welding machines, shearing machines and pipe bending machines, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware industries.Welcome to consult online to learn more about the machine information.