A complete guide to the selection and maintenance of hydraulic oil for bending machines: key elements to achieve optimal equipment performance

The hydraulic system is the "blood circulation system" of the bendingmachine, and its oil quality and capacity directly affect the performance of theequipment. Correct hydraulic oil selection and maintenance can:

Ensure maximum power transmission efficiency

Extend the service life of hydraulic components by more than 30%

Reduce system failure rate by about 40%

Maintain stable bending accuracy

Reduce energy consumption by 15-20%

Accurate determination method of hydraulic oil capacity

Key factors for capacity calculation

1. Equipment model parameters: The requirements of bending machines ofdifferent tonnage and stroke vary significantly

2. Hydraulic system design: The oil volume requirements of open and closedsystems are different

3. Working environment temperature: High temperature environment requires anincrease of 5-10% oil volume margin

4. Working cycle intensity: Continuous operation equipment is recommended toincrease the oil volume by 15%

Industry standard capacity reference table

| No. | PressBrake Model | OilTank Capacity | |

| Smart+Genius | Econom | ||

| 1 | 30T1200 | 85L | 85L |

| 2 | 40T1600 | 110L | 110L |

| 3 | 63T2500 | 170L | 155L |

| 4 | 80T2500 | 175L | 170L |

| 5 | 80T3200 | 230L | 200L |

| 6 | 100T2500 | 200L | 190L |

| 7 | 100T3200 | 250L | 230L |

| 8 | 100T4000 | 320L | 300L |

| 9 | 125T2500 | 200L | 190L |

| 10 | 125T3200 | 250L | 230L |

| 11 | 125T4000 | 320L | 300L |

| 12 | 160T3200 | 310L | 290L |

| 13 | 160T4000 | 390L | 360L |

| 14 | 200T3200 | 310L | 290L |

| 15 | 200T4000 | 390L | 360L |

| 16 | 250T3200 | 360L | 330L |

| 17 | 250T4000 | 450L | 400L |

| 18 | 250T6000 | 850L | 800L |

| 19 | 300T3200 | 500L | 500L |

| 20 | 300T4000 | 600L | 600L |

| 21 | 300T5000 | 680L | 680L |

| 22 | 300T6000 | 930L | 930L |

| 23 | 400T4000 | 600L | 600L |

| 24 | 400T5000 | 680L | 680L |

| 25 | 400T6000 | 950L | 950L |

| 26 | 500T5000 | 760L | 760L |

| 27 | 500T6000 | 950L | 950L |

| 28 | 600T6000 | 1100L | 1100L |

Note: Heavy load conditions refer to daily operating time exceeding 12 hoursor load rate>80%

Hydraulic oil optimization plan and technical characteristics

Recommended oil: No. 46 anti-wear hydraulic oil

Base oil type: Class III hydrogenated base oil + synthetic ester

Viscosity grade: ISO VG 46

Applicable temperature range: -20℃ to 80℃

Oil change cycle: 2000 hours under normal working conditions/1000 hoursunder heavy load conditions

Types Of Hydraulic Oil

Core performance advantages

1. Extreme pressure and anti-wear properties: zinc-type additive formula,wear reduction by 60%

2. Thermal stability: oxidation life of more than 3000 hours

3. Filtration performance: NAS 7-level cleanliness standard

4. Environmental characteristics: biodegradability>80%

Scientific maintenance system for hydraulic systems

Daily maintenance specifications

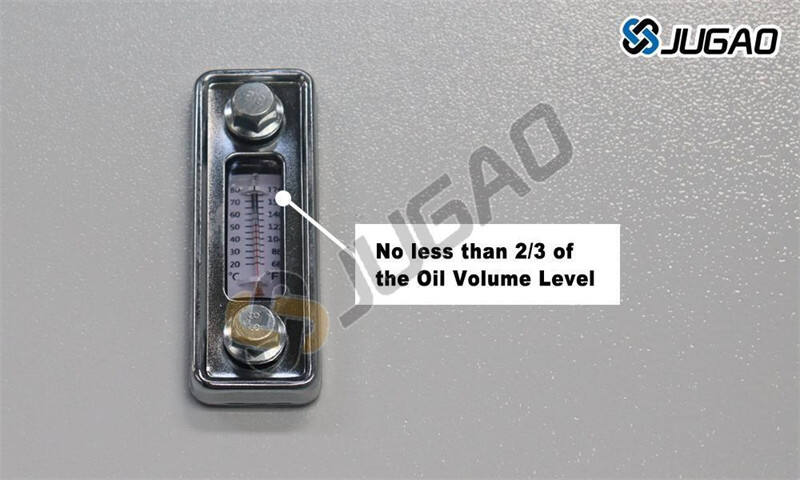

Oil level check: Visually check before starting the machine every day, keepthe oil level at 2/3 of the window

Hydraulic Oil Volume

Temperature monitoring: The working oil temperature should be maintained inthe optimal range of 40-60℃

Pollution control: Take samples weekly to test particle contamination

Professional maintenance plan

1. Every 500 hours:

Replace the oil suction filter

Test the moisture content (should be<0.05%)

2. Every 2000 hours:

Fully replace the hydraulic oil

Cleaning the oil tank

Testing the acid value (should be<1.0mgKOH/g)

3. Annual maintenance:

Hydraulic system pressure test

Evaluation of seal status

Comprehensive analysis by professional oil laboratory

Diagnosis and solution of common problems

Problem phenomenon: rapid deterioration of hydraulic oil

Possible cause: system overheating or water intrusion

Solution: Check cooling system efficiency and add water removal filter

Problem phenomenon: abnormal pump noise

Possible cause: improper oil viscosity or air intake

Solution: Detect oil viscosity index and eliminate system leaks

Problem phenomenon: slow action of actuator

Possible cause: oil contamination causes valve core to get stuck

Solution: Replace oil immediately and clean the system

By establishing a scientific hydraulic oil selection, use and maintenancesystem, it can ensure that the hydraulic system of the bending machine is alwaysin the best working condition, creating continuous and stable productionbenefits for the enterprise. Remember, high-quality hydraulic oil is not only alubricating medium, but also the "lifeline" of efficient operation ofequipment.