Operation Steps of the Press Brake

Inspection and preparation:

Confirm whether the power is connected, whether the air pressure or hydraulic pressure is sufficient, whether the machine is clean, and whether there are any obstacles on the slideway.

Make sure that all safety equipment (such as protective devices, safety helmets, etc.) are worn correctly and the work area has been cleaned.

Start the machine:

Turn on the power switch on the control panel and start the oil pump. When you hear the sound of the oil pump turning, it means that the bending machine can work normally.

Start the oil pump and align the origin of the L axis, D axis, CC axis, and Z axis to complete the starting process.

Adjust parameters:

According to the size and shape of the metal plate to be processed, adjust the parameters of the bending machine, such as stroke, gap between the upper and lower dies, bending angle, etc.

When adjusting the stroke, a gap of the plate thickness must be ensured when the upper die descends to the bottom to prevent damage to the mold and the machine. The adjustment methods include electric quick adjustment and manual fine-tuning.

Select a suitable bending notch, generally a notch 8-10 times the thickness of the plate.

The back gauge adjustment also provides electric quick adjustment and manual fine-tuning functions.

Mould loading and drawing recognition:

Install the base and the lower and upper molds, align the D-axis zero point, and lock the lower mold to complete the mold loading process.

Recognize the drawing, understand the bending sequence and bending size, and start programming the bending machine.

Trial folding and mass production:

Perform trial folding of waste materials, modify the program, and adjust the angle and size to the best state.

Perform product trial folding, and the trial folded products can be mass-produced after inspection.

Operation process:

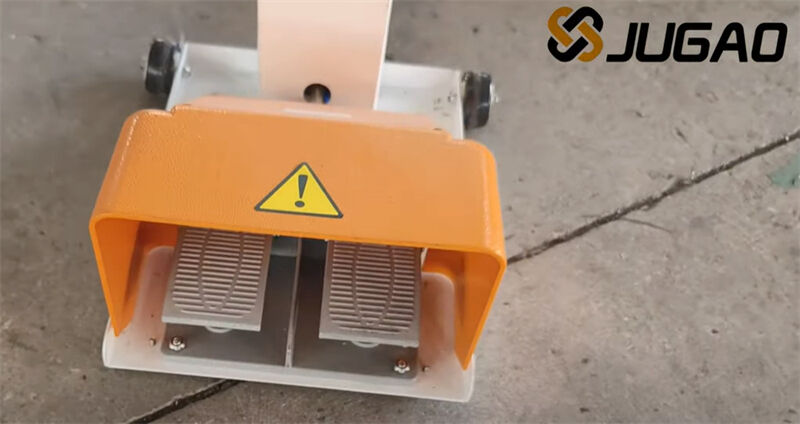

Press the foot switch to start bending. The bending machine is different from the shearing machine. It can be released at any time. The bending machine stops when the foot is released, and it continues to move downward.

Pay attention to the principle of center bending during the bending process, and avoid bending at one end of the bending machine to prevent damage to the machine.

End of operation:

After the processing is completed, turn off the bending machine first and check the processing quality of the metal sheet.

Clean the machine and the surrounding working environment. Remove the mold, put it back on the mold rack and restore the operation panel.

Please note that when operating the bending machine, be sure to follow the safe operating procedures to avoid unnecessary injuries caused by illegal operations. At the same time, regularly maintain and service the equipment to ensure its normal operation and extend its service life.

In addition, bending machines of different brands and models may differ in specific operations, so before actual operation, it is recommended to read and follow the instruction manual of the bending machine in detail.