How to Choose the Right Press Brake Size and Tonnage?

Selecting a press brake with the appropriate size and tonnage is crucial for improving production efficiency and ensuring bending accuracy. This guide synthesizes key factors and practical methods to help you make informed decisions, optimize workflows, and reduce costs.

Core Considerations

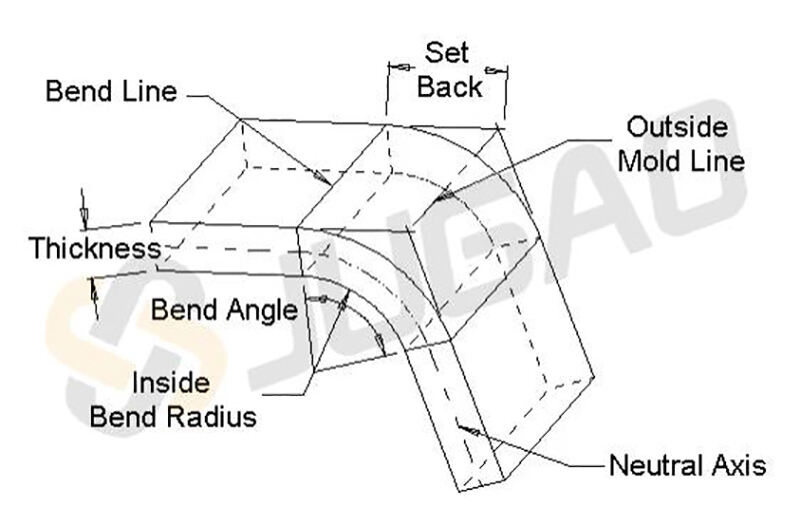

First, focus on material thickness and type. Thicker materials require higher bending force (tonnage). For example, processing thick steel plates demands a high-tonnage machine, while thinner aluminum sheets can be handled with a lower-tonnage model. If working with diverse materials, prioritize matching the thickness of the most frequently processed material while ensuring adaptability to others.

Bending length is another critical factor. Measure the longest workpiece you plan to bend and select a press brake with extra capacity. For instance, if your longest workpiece is 3 meters, choose a machine with a bending length of at least 3.2 meters to avoid production delays. Additionally, complex bending operations (e.g., multi-axis bends or precision forming) may require more flexible tooling or CNC systems, so assess these functional needs in advance.

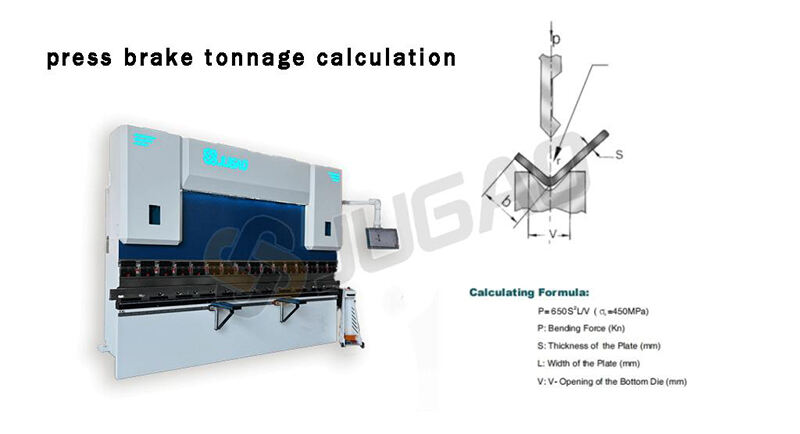

Precision Tonnage Calculation

Insufficient tonnage leads to poor bending accuracy or machine overload, while excessive tonnage increases costs and energy consumption. To calculate required tonnage, use the formula:

Tonnage = (Material Thickness × Bending Length × Material Factor) ÷ 1000

Material factors vary by type—e.g., 80 for steel and 30 for aluminum. This formula helps estimate tonnage quickly, ensuring the machine’s capacity aligns with actual needs.

Scalability and Flexibility

Tool compatibility directly impacts productivity. Confirm that the press brake supports your existing tooling. Some models allow quick tool changes, enhancing operational flexibility. Additionally, plan for future needs. For example, if you currently process small-to-medium workpieces but may handle larger or thicker materials later, choosing a slightly higher-capacity machine avoids frequent upgrades.

Common Pitfalls and Solutions

Using an undersized press brake for large materials might save costs temporarily but risks inaccurate bends or machine damage. For mixed-size workpieces, consider modular designs or expandable models. When calculating bending length, account for clamping space and operational clearance to avoid mechanical interference.

Conclusion

Choosing the right press brake requires balancing current needs with future scalability. By accurately calculating tonnage, evaluating material properties and bending lengths, and considering machine functionality and tool compatibility, you can maximize productivity and product quality. For personalized recommendations, consult technical experts to ensure your investment delivers long-term value.