Master the leveling technology of bending machines: the key step to achieve high-precision bending Why leveling is so important for bending accuracy

In the field of sheet metal processing, the leveling of bending machines is the basic link to ensure processing accuracy. An unleveled bending machine will not only cause product size deviation and angle inconsistency, but may also accelerate machine wear and even cause safety hazards. After precise leveling, the bending machine can ensure:

Even distribution of material force

Highly consistent bending angle

Precise product size

Extend equipment service life

Improve operational safety

Professional leveling operation guide

1. Basic preparation

Before starting leveling, you must ensure:

The equipment is completely powered off and all safety devices are in place

The work surface is clean and free of debris

Prepare a high-precision level (recommended 0.02mm/m accuracy)

Prepare leveling gasket sets of different thicknesses

2. Foundation inspection and treatment

Use a laser level to check the foundation for equipment installation, with the following requirements:

The foundation load-bearing capacity must reach 1.5 times the weight of the equipment

The level deviation does not exceed 0.1mm/m

If unevenness is found, the foundation must be corrected first

3. Precision leveling process

1. Preliminary inspection: Place the level meter at multiple locations on the workbench and record the data at each point

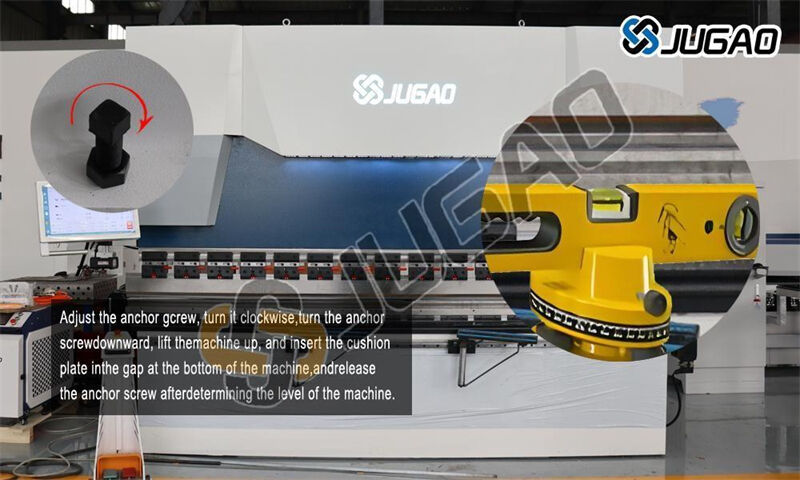

2. Adjust the feet: Prioritize adjusting the leveling feet that come standard with the equipment

3. Shim compensation: For areas where the feet cannot be adjusted, use stainless steel shims for fine-tuning

4. Secondary verification: Use diagonal measurement to ensure overall levelness

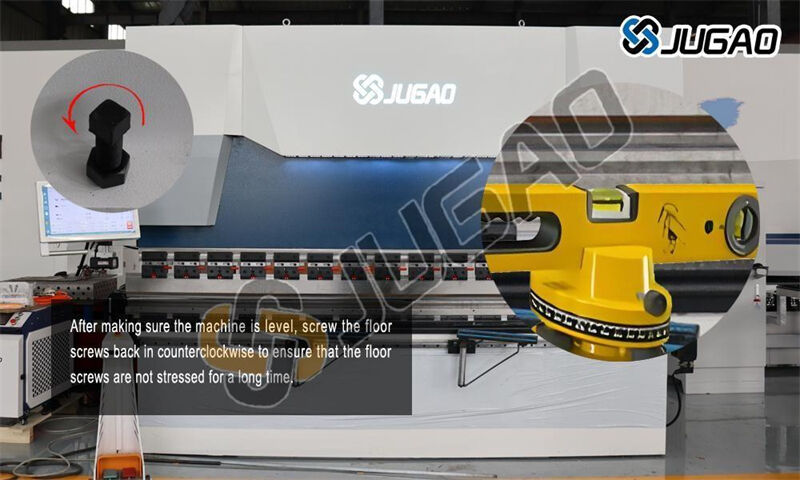

5. Fix and fix:Use a torque wrench to tighten the fixing bolts to the specified torque

4. Verification and testing

After leveling is completed, the following must be done:

Static retest: recheck the level after an interval of 1 hour

Dynamic test: perform actual bending test

Sample test: use a three-coordinate measuring machine to check the accuracy of the test piece

Advanced leveling techniques

For large bending machines, it is recommended to:

Use an electronic level with professional leveling software

Perform final leveling after the equipment is preheated

Consider the impact of workshop temperature changes on the equipment

Establish a leveling data record file

Maintenance specifications

To ensure long-term accuracy, the following should be established:

Weekly quick inspection system

Monthly comprehensive inspection plan

Quarterly professional calibration

Instant re-inspection after environmental changes

Solutions to common problems

Problem 1: Inconsistent bending angles still occur after leveling

Check mold wear

Confirm hydraulic system pressure balance

Check slide parallelism

Problem 2: Levelness changes after equipment has been used for a period of time

Check foundation settlement

Confirm whether the anchor bolts are loose

Consider temperature deformation factors

Through this systematic leveling method, operators can ensure that the bending machine is always in the best working condition, providing a solid foundation for high-quality production. Remember, accurate leveling is not only the first step in equipment installation, but also the key to ensuring long-term processing accuracy.