How to Install a Proportional Valve on a Press Brake?

Table of Contents

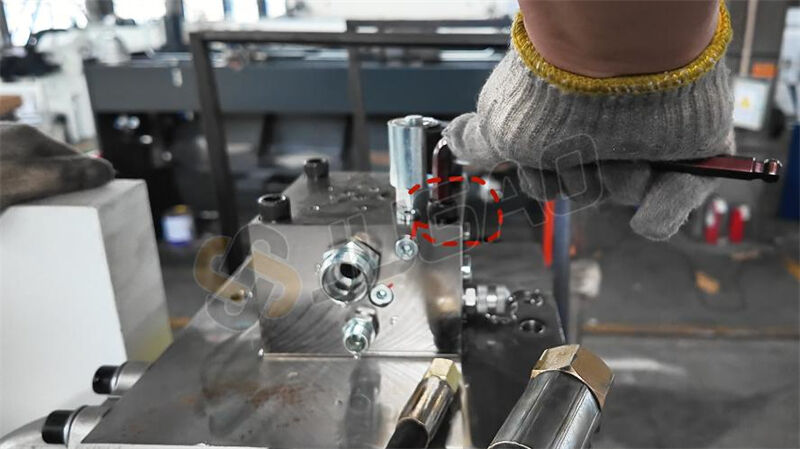

1. Mounting the Proportional Valve – Using a 10mm Allen Key

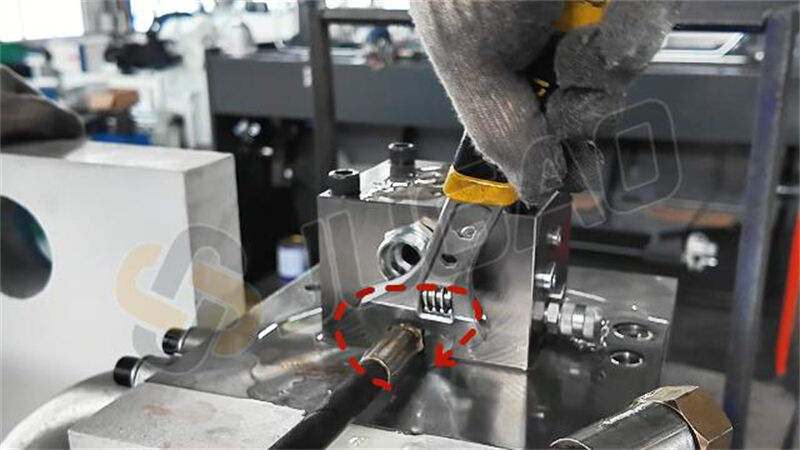

2. Installing the Quick-Exhaust Valve – Using a #24 Spanner

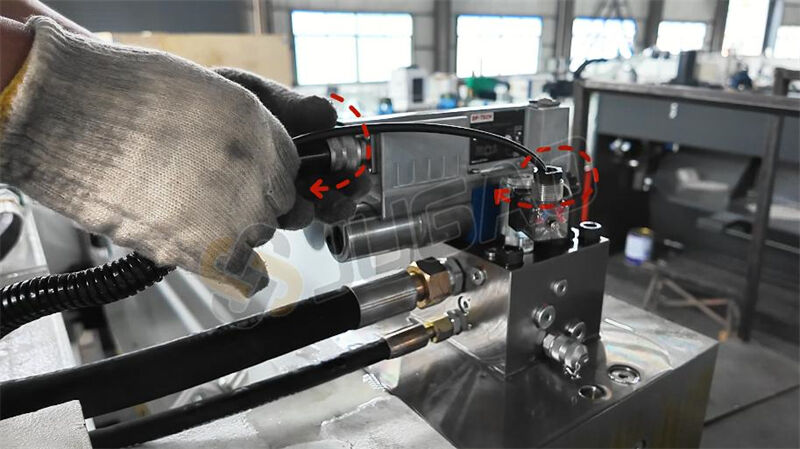

3. Connecting the Hydraulic Line – Using #36 and #19 Spanners

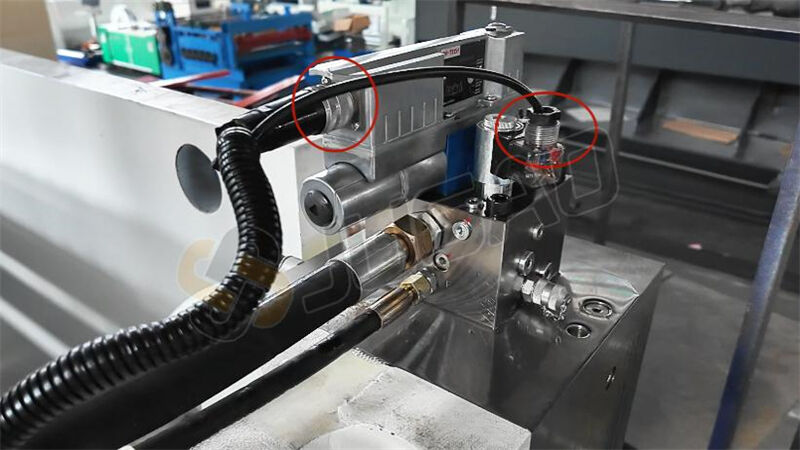

4. Wiring and Securing – Tighten Clockwise

5. Video Demonstration

Importance of Proportional Valve Installation

Proper installation of the proportional valve directly affects the press brake’s control accuracy and operational stability. Correct installation ensures:

Smoother bending operations

More precise pressure control

Higher machine efficiency

Pre-Installation Preparation

Upon receiving your JUGAO CNC press brake, the proportional valve is typically disassembled for shipping. Follow the steps below for proper installation to ensure optimal machine performance.

1. Mounting the Proportional Valve (Using a 10mm Allen Key)

Steps:

1. Align the proportional valve with its mounting position on the hydraulic manifold.

2. Use a 10mm Allen key to tighten the bolts in a crisscross pattern, ensuring even pressure distribution.

3. Avoid over-tightening to prevent damage to the valve or seals.

4. After installation, check for stability and ensure no misalignment or looseness.

Notes:

Proper installation extends valve lifespan and maintains stable hydraulic pressure.

Always follow JUGAO’s technical specifications for best results.

2. Installing the Quick-Exhaust Valve (Using a #24 Spanner)

Steps:

1. Ensure the hydraulic system is powered off and depressurized for safety.

2. Align the quick-exhaust valve with its port and hand-tighten initially.

3. Use a #24 spanner to secure it firmly, ensuring a leak-free seal.

4. Verify proper alignment and avoid excessive force.

Notes:

Over-tightening may damage the valve or fittings.

After installation, restart the hydraulic system and check for leaks.

3. Connecting the Hydraulic Line (Using #36 and #19 Spanners)

Steps:

1. Inspect the hydraulic line and fittings for cleanliness to prevent contamination.

2. Align the line with the proportional valve and hydraulic system ports.

3. Use a #36 spanner to hold the larger nut while tightening the smaller fitting with a #19 spanner.

4. Ensure a secure connection without over-tightening

Notes:

Check for leaks after installation.

Ensure smooth hydraulic flow to maintain system performance.

4. Wiring and Securing (Tighten Clockwise)

Steps:

1. Refer to JUGAO’s wiring diagram to connect cables to the correct terminals.

2. Position the valve securely before tightening.

3. Use a spanner to tighten clockwise and fix the bolts.

4. Secure all screws to prevent loosening during operation.

Notes:

Ensure correct polarity to avoid short circuits or signal interference.

Test the hydraulic system after installation to confirm proper valve function.

5. Video Demonstration

For a visual guide, refer to JUGAO’s proportional valve installation video to ensure accurate step-by-step execution.

Conclusion

Proper proportional valve installation is crucial for optimal press brake performance. Following this guide ensures:

✅ Precise pressure control

✅ Stable bending performance

✅ Longer machine lifespan

For further assistance, contact JUGAO Technical Support for expert guidance!