The Incredible Metal Pipe Bending Machine: Revolutionizing the Manufacturing Industry

Introduction:

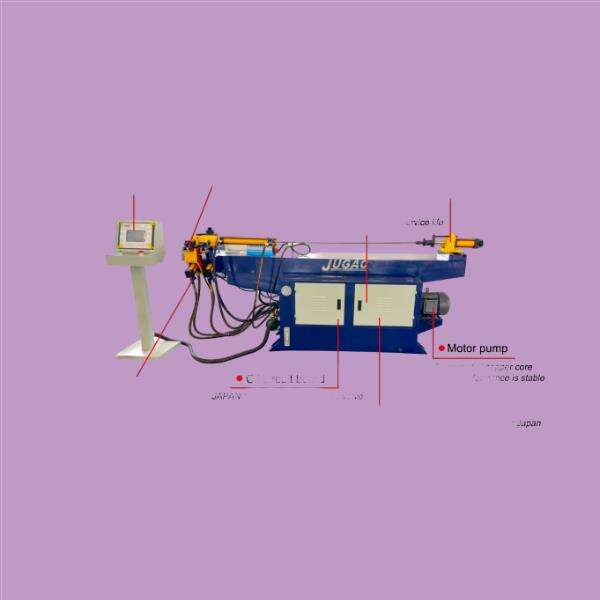

Metal pipe bending machines are essential equipment in the manufacturing industry, as well as the JUGAO's pipe bending machine. These machines allow manufacturers to bend pipes into various shapes and sizes according to their requirements. If you are looking for an efficient, reliable, and safe machine that can make your manufacturing process faster and more precise, then a metal pipe bending machine is an excellent investment. We will explore the advantages, innovation, safety, use, quality, application, and service of metal pipe bending machines.

Metal pipe bending machines have numerous advantages, same with the lazer welders built by JUGAO. One of the primary benefits of these machines is that they can bend metal pipes into almost any desired shape or angle. This level of flexibility allows manufacturers to create unique designs that were previously not possible. Another advantage of metal pipe bending machines is that they can produce pipes of various lengths, thickness, and diameters. This capability makes these machines suitable for a wide range of manufacturing processes.

The innovation of metal pipe bending machines is evident from the various features incorporated in the latest models, the same as JUGAO's steel plate bending machine. Current models come equipped with advanced software and automated systems that simplify the pipe bending process. Furthermore, these machines employ advanced technologies like CNC controlled bending systems and robotic arms, which make the process more accurate and precise. The result is a machine that can bend pipes with incredible accuracy and speed.

Safety is of utmost importance, especially when dealing with heavy machinery, identical to metal pipe bending machine by JUGAO. Metal pipe bending machines come with various safety features to ensure that the user is protected while operating the machine. For instance, the machines feature emergency stop buttons, protective barriers, and safety interlocks that prevent the machine from operating unless all safety measures are in place. The machines operate at relatively low noise levels, reducing the risk of hearing damage.

The use of metal pipe bending machines is relatively straightforward, similar to the JUGAO's product like metal plate rolling machine. You load the pipe into the machine, set the desired angle and radius, and let the machine do the rest. The latest models come with user-friendly software that allows operators to input the desired bending specifications easily. Furthermore, these machines have a relatively small footprint and can operate in tight spaces, providing excellent versatility.

Metal pipe bending machine Machines specialize metal sheet forming production quality. Pipe Bending Machines flexible solutions pipe bend. range products focused precision, efficiency, stability order increase effectiveness quality products.

appreciate importance RD after-sales support. offer complete variety after-sales products include Spanish-speaking after-sales press brakes well as other products. continue invest product development upgrade using latest technologies. helps meet changing needs customers keep position leader Metal pipe bending machine.

their precision efficacy laser cutting machines Metal pipe bending machine range different materials. Rolling machines thanks excellent forming abilities efficient production meet needs many customers. Mass production requirements; Pipe Bending machines ideal variety pipe processing thanks flexible bending capabilities long-lasting performance. products embody essence latest industrial technology allow manufacturing industry tackle various challenges effectively, accurately flexibly.

Quality Builds Trust: Metal pipe bending machine sheet metal machines meticulously supervise quality control ensure machine is line industry standards. strive provide highest quality products customers. laser cutters press brakes, pipe bending well as rolling machines.Rapid Market Response: leveraging efficient production supply chain management, we able quickly meet market demands. ample inventory, delivery time reduced week, enabling prompt equipment acquisition market advantage.

To use a metal pipe bending machine, you start by preparing the pipe that you want to bend, same with the laser weld machine price created by JUGAO. This preparation involves ensuring that the pipe is the correct length and diameter. You then turn on the machine and load the pipe into the device's feeding mechanism before setting the desired bending angle and radius. After inputting the specifications, the machine will start bending the pipe automatically. Once the bending process is complete, you can remove the bent pipe and repeat the process for the next pipe.

At every stage of the manufacturing process, having reliable equipment is of the utmost importance, as well as the JUGAO's rolling sheet metal. In the event of a breakdown or malfunction, it is essential to have access to excellent after-sales service. Metal pipe bending machine manufacturers offer a wide range of service packages, installation, training, maintenance, and repair services. These services ensure that your machine remains functional and operational throughout its lifetime.

The quality of a metal pipe bending machine is essential to the manufacturing process, along with the laser cutter for sale from JUGAO. A poor quality machine can negatively impact the final product's quality, while a high-quality machine can ensure precision, accuracy and produce a superior final product. It is essential to choose a metal pipe bending machine manufacturer with a reputation for producing high-quality machines.