How to adjust the pressure imbalance of the press brake

Are you facing challenges with inconsistent bending angles on your NC press brake? Understanding the underlying causes and implementing targeted solutions can help you achieve precise and repeatable results.The methods of adjusting the pressure imbalance of the press brake mainly include solving external factors and machine internal factors. First of all, it is necessary to determine the cause of the pressure imbalance, which usually includes external factors and machine internal factors. External factors such as nearby heavy objects affect the uneven force of the sliders on both sides of the working cylinder, while the machine internal factors may be due to the two working cylinders pressurizing at both ends of the slider, causing the working center of gravity to deviate to the middle, thereby affecting the molding and subsequent work of the product.

Solution

Solve external factors: remove the heavy objects that affect the operation of the press brake, and ensure that the sliders on both sides of the working cylinder are evenly stressed.

Solve the machine's own factors: adopt the deflection compensation and pressure compensation methods, and place the deformation amount opposite to the force deformation direction on the workbench to achieve variable compensation for the slider and the workbench, so as to make the pressure distribution of the working cylinder sliders on both sides of the press brake more uniform.

Specific steps

Adjustment of external factors:

Remove heavy objects that affect the operation of the press brake.

Ensure that there are no foreign objects on the press brake body, and always pay attention to the working conditions of the press brake to reduce the occurrence of uneven pressure on both sides.

Adjustment of machine internal factors:

Place a deformation amount in the opposite direction of the force deformation on the workbench between the slider and the upper die of the press brake to achieve deflection compensation.

Use hydraulic compensation and mechanical compensation to achieve pressure compensation.

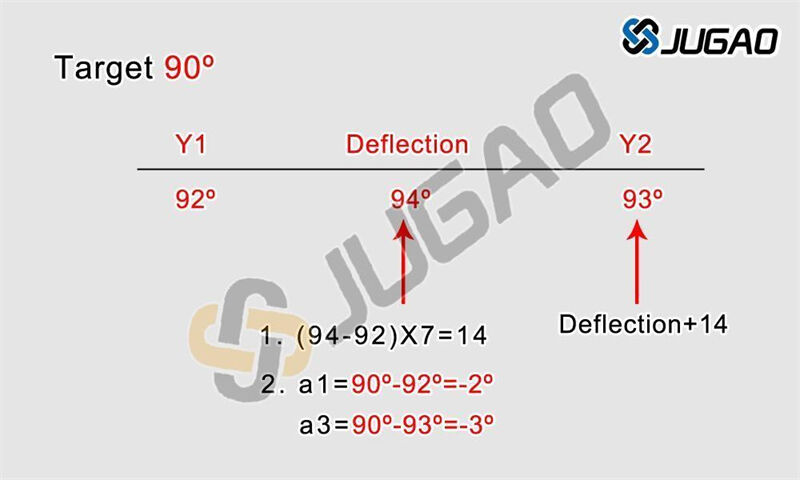

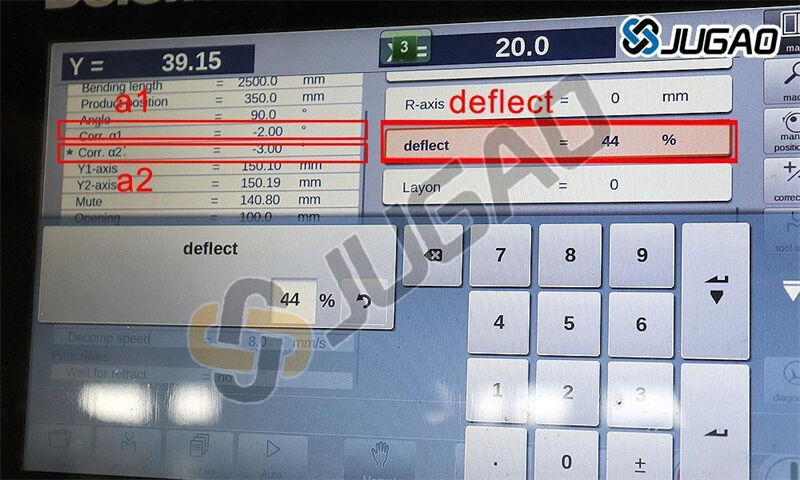

Take the following figure as an example

Inspect and Align Tools

Misaligned or worn tools are a common culprit behind angle discrepancies. Ensure the upper and lower dies are properly aligned and free from damage. Replace any worn components to maintain accuracy.

Recalibrate the CNC Controller

Over time, the machine’s controller may drift from its original settings. Recalibrate the CNC system to ensure it accurately interprets and executes bending commands.

Verify Material Consistency

Variations in material thickness, hardness, or grain direction can affect bending outcomes. Check the material properties and ensure uniformity before proceeding with the bending process.

Perform Regular Maintenance

Routine maintenance, including lubrication, hydraulic system checks, and mechanical inspections, can prevent many issues before they arise. A well-maintained machine operates more reliably.

Fine-Tune Machine Settings

Adjust parameters such as bending speed, pressure, and back gauge position to optimize performance for specific materials and designs.

Troubleshooting Common Scenarios

A frequent issue encountered with hydraulic NC press brakes is inconsistent angles along the same bending line. For instance, a target angle of 90° may result in 89° on one side and 91° on the other. This problem often stems from uneven pressure distribution or misalignment.

By systematically addressing tool alignment, controller calibration, and material checks, you can restore precision to your bending operations.

Precautions

* Before using the press brake, ensure that there are no foreign objects on the machine body and always pay attention to the working condition of the press brake.

* Clean and maintain the press brake regularly to reduce the frequency of failures.

* Follow the specific operating instructions in the manufacturer's manual to ensure safe and effective adjustments.

Conclusion

Maintaining consistent bending angles requires a combination of proper machine setup, regular upkeep, and attention to material details. Follow these best practices to minimize errors and enhance the efficiency of your NC press brake.