A Comprehensive Guide to Budget Planning for Press Brake Procurement

Table of Contents

1. Complete Breakdown of Press Brake Procurement Costs

2. Three-Step Methodology for Accurate Budget Planning

3. Three Critical Budgeting Pitfalls to Avoid

4. Expert Answers to Common Procurement Questions

5. Professional Procurement Recommendations & Conclusion

In the era of manufacturing transformation, press brakes—as core metal-forming equipment—directly impact production efficiency and market competitiveness. A well-structured budget plan not only controls initial investment but also ensures optimal operational performance throughout the equipment's lifecycle. This guide provides a systematic approach to press brake budget planning, helping businesses maximize return on investment (ROI).

Complete Breakdown of Press Brake Procurement Costs

Equipment Acquisition Cost Analysis

Press brake pricing varies significantly based on:

Automation level: Manual models cost a fraction of CNC or fully automated systems.

Processing capacity: Tonnage and bed length directly influence pricing.

Brand premium: Imported brands typically command a 30%-50% price premium over domestic alternatives.

Recommendation: Adopt a "requirements-matching" approach to select the most cost-effective model for your production needs.

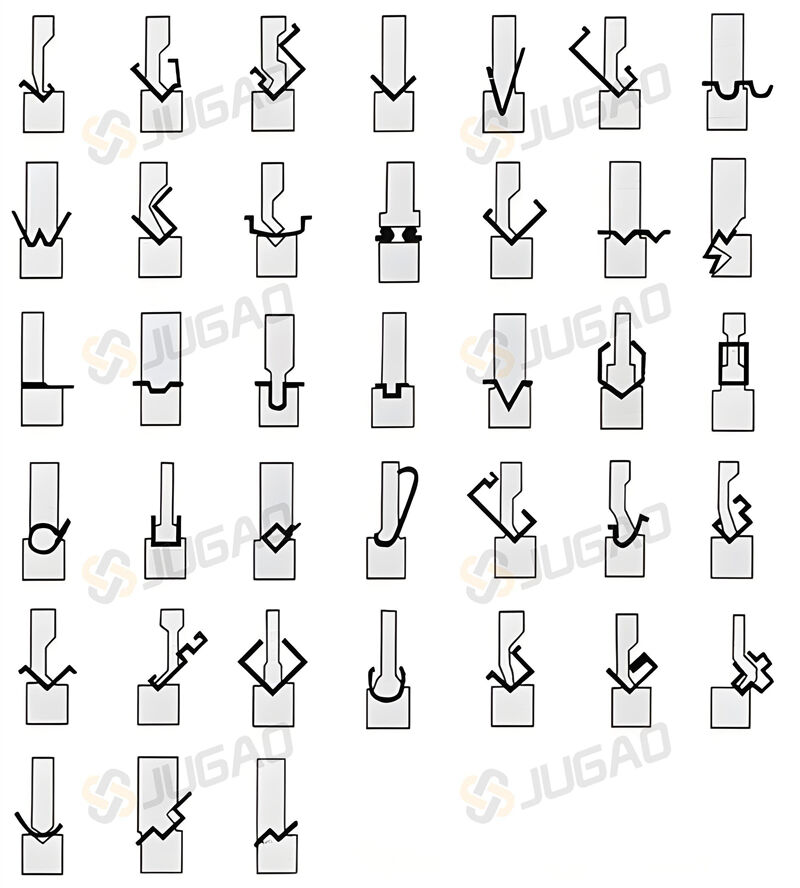

Tooling Investment Strategy

Tooling accounts for 15%-25% of total investment. Key considerations:

1. Standard tooling: Cover 80% of routine bending requirements.

2. Specialized tooling: Plan for unique forming applications.

3. Tooling lifecycle management: Implement predictive replacement schedules.

Total Lifecycle Operational Cost Calculation

Include:

Energy consumption: Hydraulic models consume ~40% more power than servo-electric systems.

Labor costs: Automation can reduce operator headcount by 50%.

Facility modifications: Large machines may require reinforced flooring.

Smart Maintenance System Implementation

Best practices:

Preventive maintenance: Extends equipment lifespan by 30%.

Critical spare parts inventory: Minimizes unplanned downtime.

Remote monitoring: Enables predictive maintenance.

Three-Step Methodology for Accurate Budget Planning

Step 1: Needs Assessment & Machine Selection

1. Define technical requirements for parts production.

2. Evaluate annual production volume.

3. Determine automation level (manual/hydraulic/CNC).

4. Shortlist 3-5 candidate models.

Step 2: Comprehensive Cost Modeling

Recommended budget allocation:

Equipment purchase: 55%-65%

Tooling: 15%-25%

Installation/commissioning: 5%-8%

Operator training: 3%-5%

Operational reserve: 7%-10%

Step 3: ROI Analysis Framework

Key metrics:

Per-part processing cost

Machine utilization rate

Payback period

5-year total cost of ownership (TCO)

Three Critical Budgeting Pitfalls to Avoid

Pitfall 1: Price-Driven Procurement Decisions

Case study: A manufacturer saved $30K upfront by choosing an under-spec machine, only to incur $50K/year in additional labor costs.

Pitfall 2: Overlooking Hidden Costs

Common omissions:

Process debugging expenses

Operator certification fees

Environmental compliance investments

Pitfall 3: Static Budget Planning

Solution: Implement quarterly budget reviews to adapt to market changes.

Expert Answers to Common Procurement Questions

Q: How to Balance Machine Capability vs. Budget Constraints?

A: Follow the "core requirements first" principle—ensure critical specs are met while compromising on non-essential features.

Q: How to Establish Optimal Maintenance Intervals?

A: Base schedules on runtime data:

Every 400-500 hours: Routine maintenance

Every 2,000 hours: Comprehensive service

Annually: Full system inspection

Q: Strategies to Reduce Operational Costs Post-Purchase?

A: Key measures:

1. Implement energy monitoring systems

2. Standardize operating procedures

3. Conduct continuous improvement programs

Professional Procurement Recommendations & Conclusion

4. Form a cross-functional procurement team

5. Compare ≥3 qualified suppliers

6. Demand detailed lifecycle cost analyses

7. Negotiate favorable payment terms

8. Clarify after-sales service agreements

Conclusion: Scientific budget planning is the cornerstone of successful press brake procurement. By adopting a "Total Cost of Ownership" mindset—balancing upfront costs with long-term operational efficiency—manufacturers can maximize equipment value. For customized procurement solutions, consult our technical experts.