How much do you know about clamping systems for torsion press brakes?

It's widely acknowledged that sheet metal bending accuracy depends on several key factors: the performance of the bending equipment, the quality of the tooling system (including the tooling itself, fixtures, and compensation mechanisms), the material characteristics, and the operator's skills. In a torsion press brake, the tooling system consists of three core components: the bending tool, the clamping system, and the compensation system. While the bending tooling and compensation system are highly regarded for their role in precision, the equally important clamping system is often overlooked. This article aims to explain the role of the clamping system, its impact on operational efficiency, and how it helps achieve higher bending accuracy.

Sheet metal parts typically undergo multiple value-added processes, such as punching, laser cutting, and deburring, before entering the bending stage. Therefore, the bending process must deliver exceptional precision and consistency to minimize waste and control costs. While high-quality bending equipment is widely recognized as crucial, the role of advanced clamping systems is often underestimated. An efficient clamping system not only reduces setup time, but also improves repeatability and reduces the need for trial bends. So, what exactly is a clamping system? The following sections explore the characteristics, advantages, and limitations of different types of clamping systems.

Types of Clamping Systems

Press brake die clamping systems fall primarily into two categories: manual and automatic. Each clamping system is available in a variety of configurations to meet different operational needs.

Manual Clamping Systems

Manual clamping systems are a cost-effective and practical solution for operations with infrequent die changes. While inherently simple, manual clamping systems can be labor-intensive and time-consuming, requiring the operator to tighten each clamping plate individually. A significant drawback of this approach is the lack of integrated calibration: as the clamping plates are tightened individually, the clamping force is often applied unevenly along the die. This inconsistency makes it difficult to achieve proper alignment immediately, often requiring time-consuming adjustments and highly skilled operators.

To reduce reliance on manual labor, minimize adjustments, and improve accuracy, some manual systems incorporate a clamping pin mechanism. This design helps distribute the clamping force evenly across the entire working length of the die. Therefore, once each die segment is secured in place, no further adjustments are required. These enhanced manual systems often include built-in automatic positioning and calibration features, ensuring fast and precise tool alignment and consistent bending results.

Automatic Clamping System

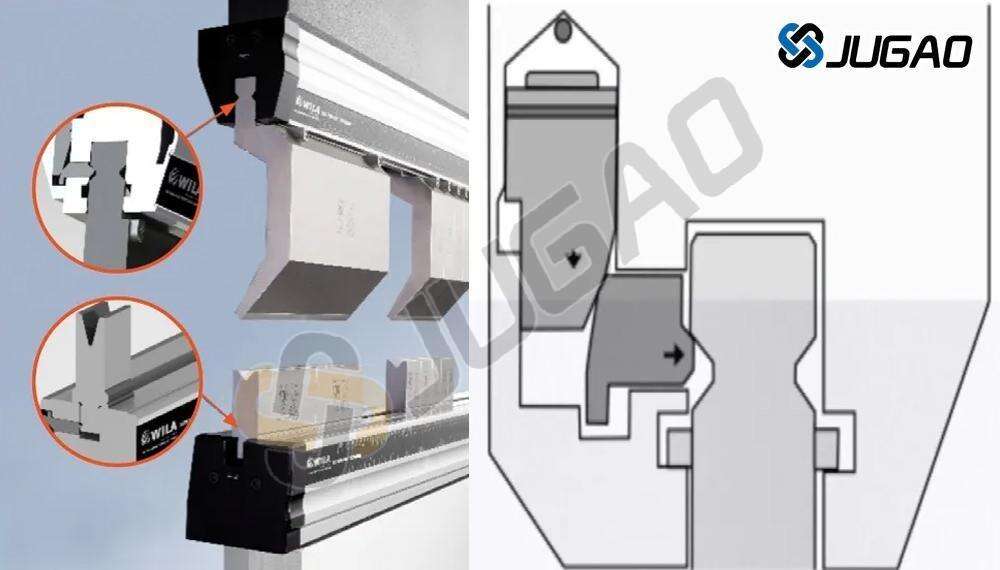

Automatic clamping systems are ideal for press brakes with frequent and rapid die changes, and are particularly suited for small-batch, high-mix sheet metal processing. Based on the "single-point operation" concept, automatic clamping systems clamp and release the die with a single button, eliminating cumbersome manual clamping. Unlike segmented, independent clamping plates, the WILA automatic clamping system utilizes a single-piece assembly, ensuring overall fixture accuracy and improving die clamping efficiency. This allows small segments to be mounted vertically or horizontally anywhere in the fixture.

Hydraulic Automatic Clamping System

The hydraulic automatic clamping system automatically clamps the mold by applying hydraulic oil at a certain pressure. The expansion of the hydraulic oil pipe pushes the hardened clamping pins outward, thereby automatically clamping the mold. The hydraulic automatic clamping system has the following features:

(1) Precision: The integrated clamp features a uniform positioning reference surface, achieving ultra-high dimensional accuracy. The clamp's parallelism can be adjusted once, ensuring long-term use.

(2) Durability: Made of high-quality tool steel/high-strength CrMo alloy steel, it has a maximum load capacity of 800 tons/meter and a hardness of 56-60 HRC after heat treatment.

(3) Flexibility: The clamp features built-in Tx/Ty adjustment, effectively compensating for machine processing errors during installation. There's no need to pad paper or tap clamps to adjust angles later.

(4) Speed: The mold automatically seats and the bending line is automatically aligned, permanently eliminating tool setting. A 6-meter-long mold can be fully clamped in just 5 seconds, increasing overall efficiency by 3-6 times compared to conventional clamping systems.

⑸ Safety: When used with molds equipped with the Safety-Click safety button mechanism, installation and removal are safer.

Pneumatic Automatic Clamping System

In a pneumatic automatic clamping system, after a certain pressure of gas is introduced, the pressure in the cylinder pushes the piston rod, causing the clamping pin to extend, thereby automatically clamping the mold. In addition to the features of the hydraulic clamping system described above, the pneumatic automatic clamping system also offers unique advantages:

(1) Cleanliness: No hydraulic oil or hydraulic drive unit is required.

(2) Simplicity: Pneumatic clamping with a self-locking mechanism (premium series).

(3) Convenience: Standard workshop compressed air power of 6-8 bar is sufficient.

(4) Speed: Ultra-fast clamping speed for higher efficiency.

(5) Economical: Lower operating costs.

Intelligent Optional Features

The WILA automatic clamping system can also be equipped with even more intelligent modules—the Intelligent Tool Positioning System and the Tool Identification and Positioning System—to further enhance bending efficiency and intelligence.

Intelligent Tool Positioning System

The core of the Smart Tool Locator (STL) system is a programmable LED-illuminated intelligent ruler. This ruler interacts with the press brake controller to guide the operator in placing the tool and the workpiece in the correct position, reducing the operator's memory requirements and the likelihood of error.

Tool Identification and Positioning System

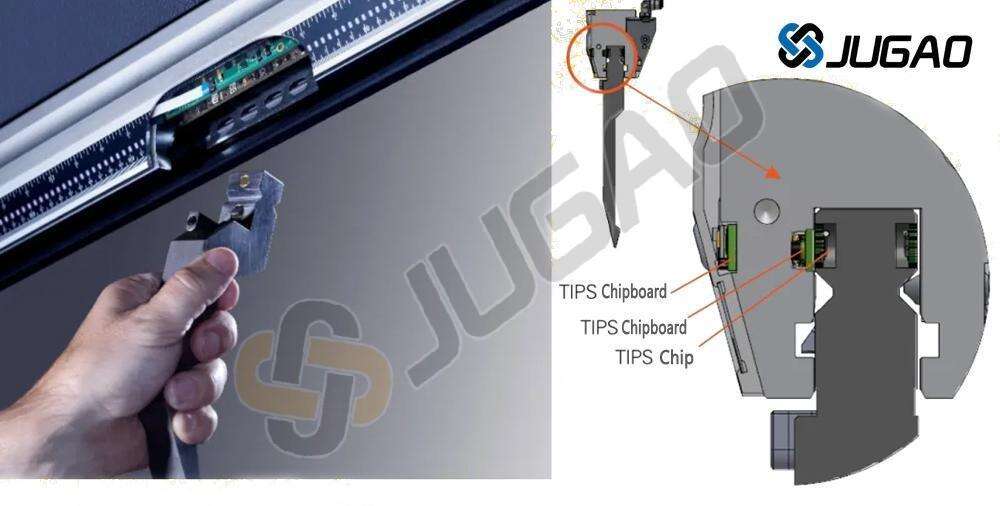

The core of the Tool Identification and Positioning System (TIPS) lies in the TIPS chip in the fixture. As shown in Figure 5, when a TIPS fixture is configured to clamp a TIPS tool, the TIPS fixture can identify all tool information, including model, length, height, and location. This information is transmitted back to the system's main controller via Ethernet, enabling fully automated bending operations, significantly improving yield and efficiency, and ultimately achieving a high return on investment.

In the highly competitive sheet metal bending industry, automatic clamping systems not only meet customer quality requirements for precision sheet metal bending, but also significantly improve bending efficiency, providing a high return on investment and meeting customer demand for automation and intelligence.