How to Choose a Press Brake Controller

A bending machine controller is the core component of a press brake,responsible for ensuring precision, efficiency, and ease of operation in metalforming processes. Selecting the right controller is crucial for optimizingproductivity, reducing errors, and improving overall workflow. This guideprovides an in-depth analysis of the key factors to consider when choosing abending machine controller.

1. Understanding press brake Controllers

A bending machine controller is an advanced CNC (Computer Numerical Control)system that manages the movement of the press brake, back gauge, and othercomponents. It processes input data (e.g., bend angle, material thickness,tooling) and executes precise bending operations.

Key Functions of a press brake Controller:

Angle Control – Ensures accurate bending angles using real-timefeedback.

Back Gauge Positioning – Controls the rear stops for consistent partdimensions.

Tool Management – Stores and selects appropriate dies and punches.

Material Compensation – Adjusts for springback based on materialproperties.

Multi-Axis Control – Manages complex bending sequences with multiple axes(Y1, Y2, X, R, Z).

User Interface (UI) – Provides an intuitive interface for programming andmonitoring.

2. Factors to Consider When Choosing a Press Brake Controller

(1) Compatibility with the Press Brake

Ensure the controller supports the machine's mechanical structure (e.g.,hydraulic vs. electric press brakes).

Check axis configurations (e.g., 2-axis, 4-axis, 6-axis).

Verify compatibility with existing tooling and automation systems.

(2) Ease of Programming & Operation

Graphical Interface – A user-friendly touchscreen with visual bendsimulations reduces setup time.

Offline Programming – Software compatibility (e.g., CAD/CAM integration)allows pre-programming bends.

Manual vs. Automatic Modes – Flexibility for both simple and complexbending operations.

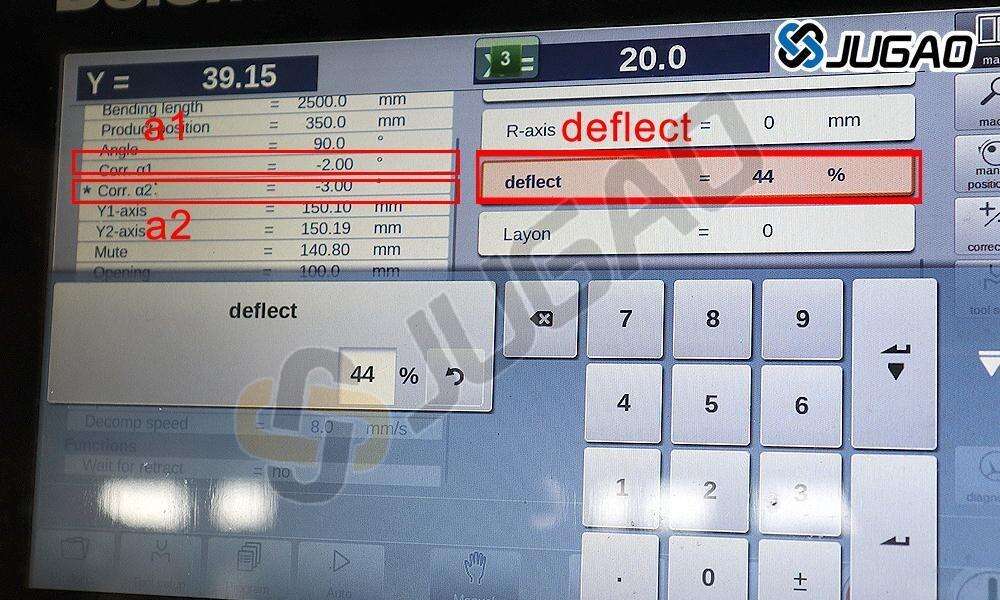

(3) Precision & Compensation Features

Real-Time Angle Measurement – Laser or probe-based systems for highaccuracy.

Springback Compensation – Automatically adjusts for materialelasticity.

Crowning Compensation – Corrects deflection in the machine bed for uniformbends.

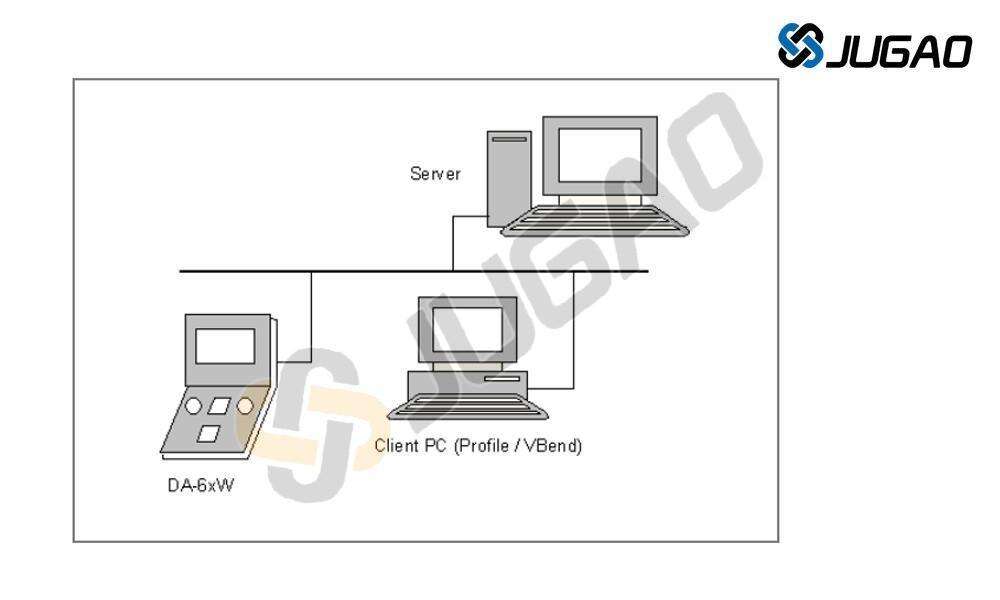

(4) Automation & Connectivity

Integration with Robots – Supports automated part handling for high-volumeproduction.

Network Connectivity – Ethernet, USB, or Wi-Fi for data transfer and remotediagnostics.

Cloud-Based Monitoring – Enables Industry 4.0 capabilities for predictivemaintenance.

(5) Software & Updates

Bend Simulation – Visualizes the bending process to prevent collisions.

Database of Materials & Tools – Pre-loaded parameters for common metals(steel, aluminum, etc.).

Firmware Updates – Ensures long-term compatibility with new features.

(6) Brand Reputation & Support

Choose controllers from reputable manufacturers (e.g., Delem, Cybelec, ESA,LVD).

Verify availability of technical support, training, and spare parts.

3. Types of Press Brake Controllers

| Type | Features | BestFor |

| BasicCNC Controllers | Simpleprogramming, 2-3 axis control | Smallworkshops, low-complexity bends |

| Mid-RangeCNC Controllers | Touchscreen,offline programming, angle correction | Mediumproduction, general fabrication |

| AdvancedCNC Controllers | Multi-axiscontrol, robot integration, cloud connectivity | High-precisionindustries, automated manufacturing |

| PC-BasedControllers | FullCAD/CAM integration, 3D simulation | Complexgeometries, aerospace, and automotive sectors |

4. Future Trends in Press Brake Controllers

AI & Machine Learning – Predictive adjustments for optimal bendingparameters.

Augmented Reality (AR) Assistance – Overlays bend instructions inreal-time.

IoT & Smart Factory Integration – Real-time monitoring and adaptivecontrol.

5. Conclusion

Selecting the right press brake controller depends on production needs,machine compatibility, and future scalability. Investing in an advanced,user-friendly, and precise controller enhances efficiency, reduces waste, andimproves part quality. Evaluate key features such as automation capabilities,software support, and manufacturer reliability before making a decision.

By following this guide, manufacturers can optimize their bending operationsand stay competitive in the evolving metal fabrication industry.

Final Recommendation:

For high-precision and automated bending, opt for controllers with real-timefeedback and Industry 4.0 compatibility. For small-scale operations, a mid-rangeCNC with an intuitive interface may suffice. Always consult with the machinemanufacturer JUGAO CNC MACHINE for the best controller match.