What are the reasons for the rapid increase in water temperature of laser cutting machines?

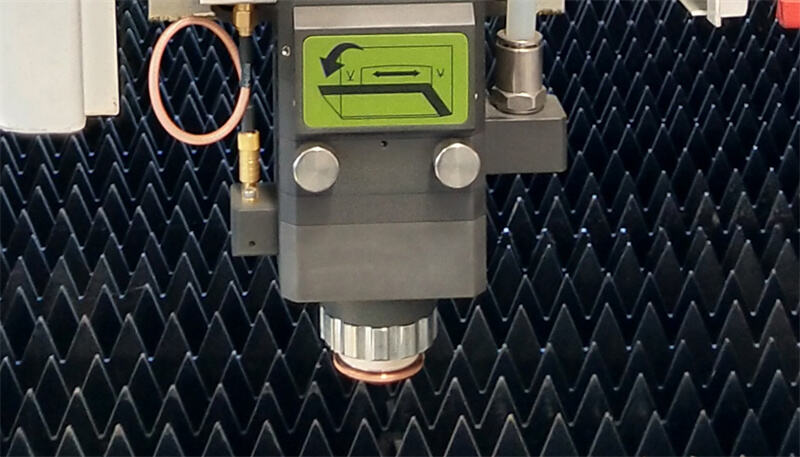

Laser cutting is achieved by applying high-power density energy generated by laser focusing. The pulsed laser beam is transmitted and reflected through the optical path and focused on the surface of the processed object through the focusing lens group, forming a fine, high-energy density spot. The focal spot is located near the surface to be processed, and the processed material is melted or vaporized at an instant high temperature.

The cutting advantages of laser cutting machines include high cutting accuracy, narrow cutting seams of laser cutting machines, smooth cutting surfaces of laser cutting machines, fast laser cutting machines, good cutting quality of laser cutting machines, no damage to workpieces, no influence of workpiece shape, and laser cutting machines can cut and process a variety of materials.

So, what are the reasons for the rapid increase in water temperature of laser cutting machines in actual use?

Analysis of the reasons for the rapid increase in water temperature of laser cutting machines:

The laser cutting machine is a laser emitted from a laser, which is focused into a high-power density laser beam through an optical path system. As the relative position of the beam and the workpiece moves, the material is eventually cut, thereby achieving the purpose of cutting. Laser cutting replaces traditional mechanical knives with invisible beams. It has the characteristics of high precision, fast cutting, no restrictions on cutting patterns, automatic typesetting to save materials, smooth incisions, and low processing costs. It will gradually improve or replace traditional metal cutting process equipment.

When using laser cutting machines in practice, many operators will find that the laser cutting machine occasionally heats up too quickly, and water plays a key role in laser cutting machines. The precautions in actual use are as follows:

1. When the laser cutting machine is operating, the surrounding ambient temperature is high, which will cause the laser cutting machine water temperature to rise too quickly.

2. The working light energy of the laser cutting machine is too large, which causes the laser cutting machine water temperature to rise too quickly.

3. The laser cutting machine has been working continuously for too long, and it is necessary to stop and rest appropriately.

4. The cooling water outlet pipe reflux is abnormal, resulting in insufficient water flow.

5. The inlet and outlet pipes of the water pump are too dirty, and the water protection is blocked, making the water flow unsmooth.

In fact, the method of troubleshooting these abnormalities is very simple and the operation is not troublesome. If the customer does not follow the correct operation method, it may also cause the water temperature to rise rapidly, warning, and affect the processing. Knowing the above reasons for the increase in water temperature, you can solve the problem yourself.

The above is the analysis of the reasons for the rapid increase in water temperature of the laser cutting machine. JUGAO CNC MACHINE's main products include laser cutting machines, fully CNC hydraulic bending machines, laser welding machines, plate rolling machines, pipe bending machines and laser application automation equipment, etc., which are used in sheet metal processing, chassis cabinets, lighting, mobile phones, 3C, kitchenware, bathroom, auto parts machining and hardware and other industries. Welcome to consult online to learn more about the machine information.